Perfect for plastic recycling, film processing, and industrial scrap size reduction, our blades provide clean cuts, heat stability, and long-lasting sharpness.

Download our company brochures and product catalogs for detailed information

Comprehensive overview of our company, products, and manufacturing capabilities

Detailed specifications and production capabilities for our industrial blades

Support OEM/ODM services, producing items like slitting knives and cutting blades based on client drawings

Provides comprehensive data on blade specifications and complete dimensional data.

Perfect for plastic recycling, film processing, and industrial scrap size reduction, our blades provide clean cuts, heat stability, and long-lasting sharpness.

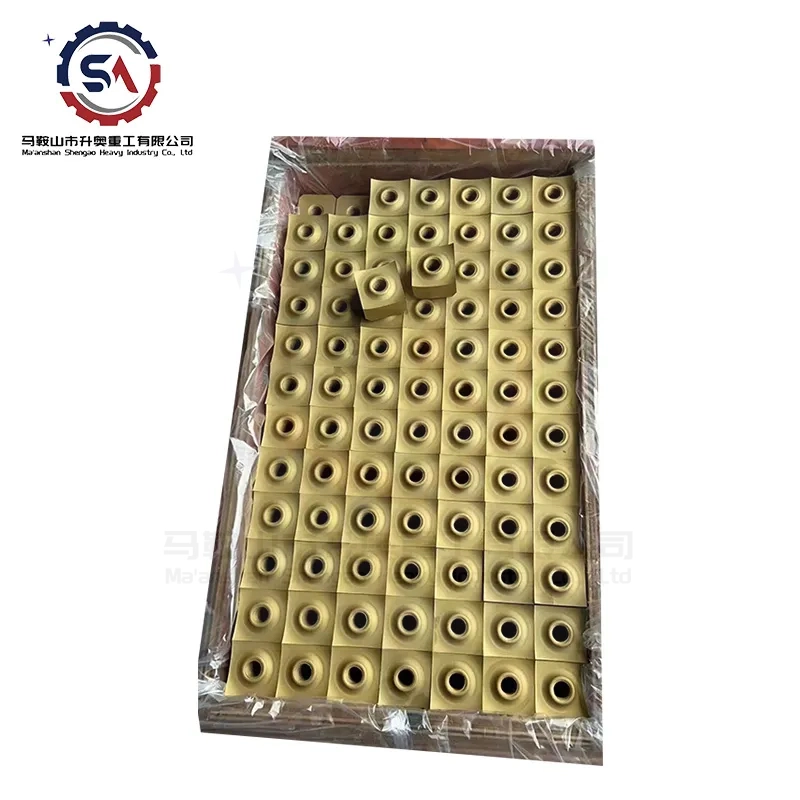

Explore ShengAo's Extended Life Plastic Crusher Blade with advanced heat treatment for superior wear resistance. Perfect for recycling ABS, PE, PP, and reducing downtime.

Our blades are engineered with high-grade tool steel and tungsten carbide for extreme durability, wear resistance, and precision cutting in recycling and size-reduction applications.

Watch this technical demo video to explore the unique design and high-hardness alloy steel of Shengao shredder blades. Ideal for recycling applications.

Watch this video to see our CNC precision grinding process in action, optimizing blade angles and hardness (HRC 58-62) for reduced wear when shredding ABS, PE, and PP plastics.

Our video showcases the quality control and precision engineering behind every tungsten carbide and tool steel blade, perfect for plastic recycling and metal fabrication.

Watch this video to explore how special shaped cutter blades—like curved, tapered, and segmented designs—handle complex cuts standard blades can’t.

Watch how ShengAo's custom-shaped cutter blades work in aerospace and food processing. See the engineering behind fray-free cuts and superior quality control.

Watch our detailed video to discover step-by-step techniques for achieving perfect, clean cuts every time using the ShengAo Paper Cutter.

Watch this video to discover how to select the ideal HSS blade. Learn about heat resistance, toughness, and cost-effectiveness from industrial experts at ShengAo.

Learn key factors like tooth geometry, pitch, and material (HSS vs. Carbide) to boost cutting precision and avoid costly downtime.

Learn how blade material (Tungsten Carbide, HSS, Bi-Metal) impacts precision, durability, and cut quality.

We break down key factors like tool material (high-speed steel, carbide), geometry, and coatings to extend blade life, improve quality control, and reduce costs.

Learn about materials like SKD11, D2, DC53 for plastics & composites, compare OEM vs. aftermarket options, and get expert maintenance tips to extend blade life.

Watch this essential guide video to master cutter selection! We break down the complexities of choosing the right blade for metals, wood, and composites into simple, actionable steps.

This video covers professional techniques including precision grinding, heat treatment for durability, and handle fitting with hardwood. Learn industrial blade quality control secrets.

ShengAo High-Performance Industrial Shredder Blades: Engineered for Maximum Durability in Metal & Plastic Recycling. Reduce Downtime & Boost Efficiency.

Engineered for excellence: Sell ShengAo chipper knives for wood processing. Features dual-tempered steel for superior durability & sharpness.

The top 3 benefits of choosing ShengAo are custom-designed blades (OEM/ODM), expert technical support for your specific application, and guaranteed compatibility with your machinery.

ShengAo offers deep customization from steel selection to claw design for optimal performance in e-waste or metal recycling.

Engineered from high-grade alloys like SKD11 and D2, our blades deliver extreme wear resistance and superior cutting power to efficiently process circuit boards and hard drives.

Discover how to match blade material (like D2, SKD11), design, and hardness to your specific plastic, wood, or rubber recycling needs.

Discover how to select the perfect blades for your machine and material (PET, PVC, PP, ABS). Maximize efficiency, reduce downtime, and cut costs.

Made from premium A8/D2 steel, they deliver longer lifespans (400+ service hours), quieter cutting, and fewer replacements. Ideal for MDF, OSB, and biomass operations.

Video demonstrates durable blades processing metal scraps, plastic waste, and wood debris with precision engineering and exceptional durability.