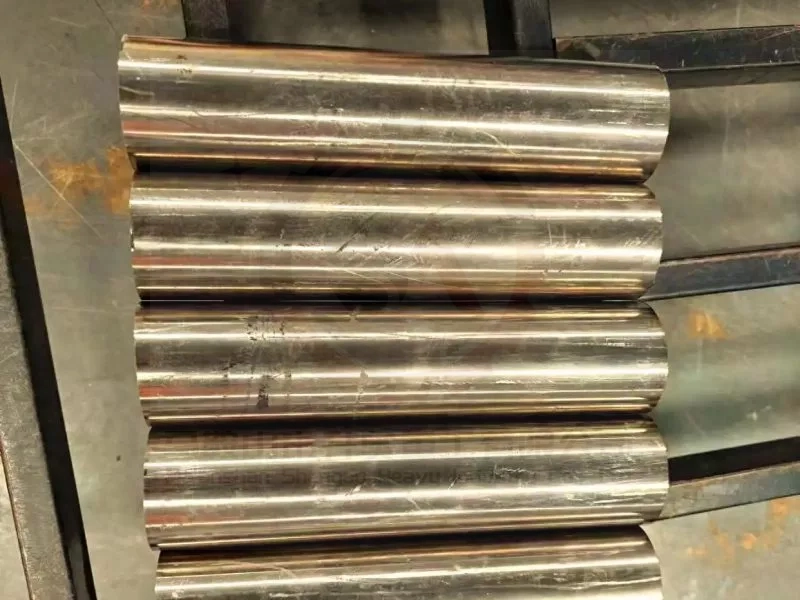

Stainless Steel Industrial Blades for Demanding Applications

Our stainless steel industrial blades are engineered for superior corrosion resistance and durability in harsh environments. Featuring food-grade AISI 304/316 stainless steel, these blades maintain optimal performance in high-moisture, chemical-exposed, and sanitary applications with hardness up to 58-60 HRC.

Material Compatibility: Specially formulated stainless steel alloys (18% chromium, 8-10% nickel) and coatings (TiN, DLC) for cutting abrasive materials including plastics, metals, composites, and food products with minimal contamination risk.

Precision Engineering: CNC grinding ensures consistent edge geometry (5-20μm sharpness) for clean cuts and extended service life, maintaining optimal cutting precision.

Corrosion Resistance: Chromium oxide layer provides exceptional protection against rust, pitting, and chemical degradation, complying with FDA/NSF standards for food contact applications.

Hygienic Design: Electropolished surfaces and non-porous finishes prevent bacterial adhesion, enabling easy cleaning and sterilization for food processing and pharmaceutical applications.

Custom Solutions: Tailored dimensions, edge geometries, and hardness levels (44-60 HRC) to match specific machine requirements and operational parameters in recycling, metal processing, and chemical industries.