Why Choose ShengAo Shredder Blades for TCM Baler Shredders?

1. Table of Contents

- Why Choose ShengAo Shredder Blades for TCM Baler Shredders?

- Key Benefits

- Comprehensive Blade Selection Guide

- Maximizing TCM Shredder Performance with ShengAo Blades

- ShengAo Blades in Action: Product Videos & Images

- Partner with ShengAo: Your Trusted Blade Specialist

- Why Customers Choose Us?

- Explore Related ShengAo Products

- Conclusion: Upgrade Your TCM Baler Shredder with ShengAo Blades

Why Choose ShengAo Shredder Blades for TCM Baler Shredders?

TCM Baler shredders are globally recognized for their robust construction and efficient processing of diverse materials, including plastics, metals, wood, and industrial waste. However, the performance of any shredder heavily depends on the quality of its blades. ShengAo shredder blades are precision-engineered to seamlessly integrate with TCM Baler single-shaft and double-shaft machines, ensuring optimal compatibility, enhanced efficiency, and extended equipment life.

Our blades undergo rigorous heat treatment processes (achieving HRC 58-62 hardness) to resist wear, impact, and abrasion, reducing downtime by up to 30% and increasing overall productivity. By choosing ShengAo blades, you're investing in durability, precision, and cost-effectiveness tailored for TCM Baler systems.

Key Benefits

Perfect Compatibility: Designed to match TCM Baler machine specifications, ensuring easy installation and smooth operation.

Superior Durability: Made from high-grade materials like SKD-11, Cr12MoV, and D2 steel, offering exceptional wear resistance.

Enhanced Performance: Precision-ground edges provide clean cuts, reduce energy consumption, and minimize material jamming.

Cost Savings: Longer blade life means fewer replacements and lower operational costs.

Comprehensive Blade Selection Guide

Selecting the right blade for your TCM Baler shredder is crucial for achieving desired output quality and efficiency. Here’s a detailed breakdown of ShengAo blades tailored for TCM machines:

Blade Types & Applications

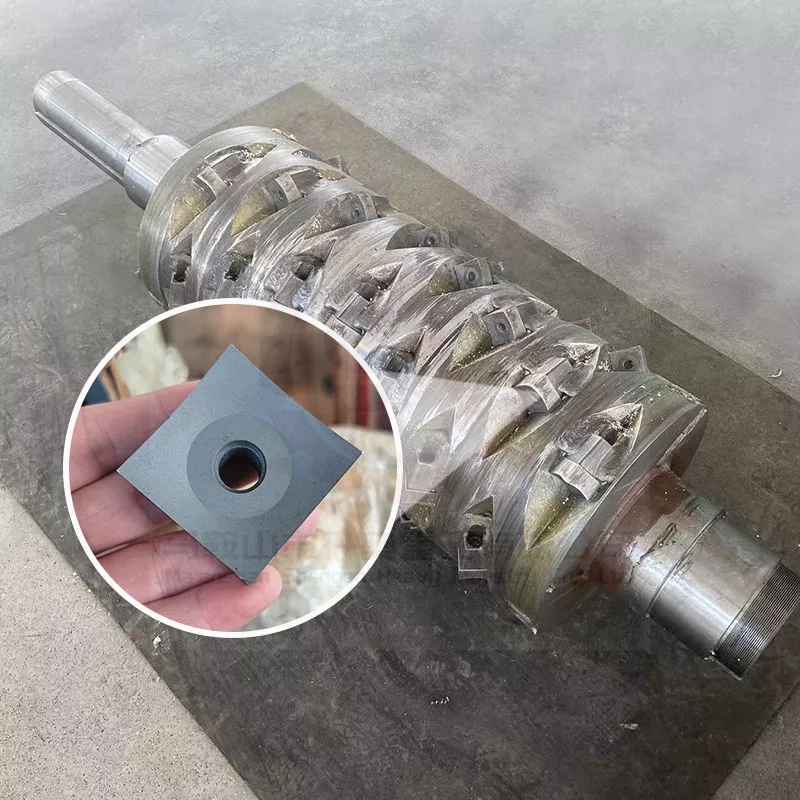

Single-Shaft Shredder Blades

Design: Square-shaped knives with custom hole patterns (convex or flat) for secure mounting.

Applications: Ideal for pre-crushing rigid materials like metals, electronics, engineering plastics, and bulky waste.

Sizes: Custom dimensions available (e.g., 60×60×30mm, 100×100×40mm).

Features: High-impact resistance, minimal vibration, and efficient material reduction.

Double-Shaft Shredder Blades

Design: Circular blades with 3-12 claws (teeth) for shear-tearing action. Claw spacing determines output particle size.

Applications: Perfect for processing bulky waste, tires, wood pallets, plastic barrels, and mixed recyclables.

Sizes: Diameters from 200mm to 800mm, thicknesses from 20mm to 100mm.

Features: Aggressive cutting geometry, reduced wrapping, and high throughput.

Material Comparison Chart

| Material | Hardness (HRC) | Best For | Advantages |

|---|---|---|---|

| SKD-11 | 58-62 | High-impact plastics, e-waste, wood | Excellent wear resistance, long lifespan |

| Cr12MoV | 58-60 | Tough metals, tires, mixed waste | Good toughness and impact resistance |

| D2/LD | 60-62 | Abrasive materials (circuit boards, alloys) | Superior hardness for extreme conditions |

| Tungsten Carbide-Tipped | HRA 90+ | Highly abrasive materials (e.g., glass-filled plastics) | Extreme durability, 5-10x longer life |

Key Specifications

Diameter Range: 100–800mm for dual-shaft; 20–200mm for single-shaft.

Thickness: 15–80mm, customizable based on machine load and material.

Claw Options: 3, 4, 8, or 12 claws for granularity control.

Bore Types: Standard circular with keyway, hexagonal, or custom drive mechanisms.

Hardness: HRC 58–62 (standard), up to HRA 90+ for carbide tips.

Maximizing TCM Shredder Performance with ShengAo Blades

To ensure peak performance and longevity, follow these expert tips:

Maintenance Tips

Regular Inspection: Check blade alignment (±0.02mm tolerance) every 500 operating hours to prevent uneven wear.

Sharpening Schedule: Professional sharpening recommended every 400–600 hours (depending on material processed). ShengAo offers sharpening services to restore original geometry.

Cleaning: Remove debris and residue after each shift to prevent corrosion and maintain cutting efficiency.

Lubrication: Apply anti-seize lubricant to bolts and mounting points to ease disassembly.

Cost-Saving Combo

Pair TCM Baler shredders with ShengAo’s pre-assembled blade sets, which include:

Blades, spacers, bolts, and washers.

Custom packaging for safe shipping.

Technical support for installation and troubleshooting.

This all-in-one solution reduces downtime and ensures compatibility, saving you time and money.

Performance Optimization

Material Testing: Send us samples of your materials for free blade recommendations.

Custom Engineering: We tailor blade geometry (e.g., claw angle, thickness) for your specific application.

Video Support: Watch our tutorial videos on blade installation and maintenance for TCM shredders.

ShengAo Blades in Action: Product Videos & Images

Note: Include high-quality images and videos here for visual reference. Below are descriptions for your content.

Video Demonstration

Title: ShengAo Shredder Blades for TCM Baler – Live Testing

Content: Shows blades processing plastic barrels, metal scrap, and tires in a TCM dual-shaft shredder. Highlights smooth operation, minimal vibration, and consistent output size.

Duration: 3 minutes.

Key Takeaways: Reduced noise, energy efficiency, and no material wrapping.

Image Gallery

Close-up of Blade Teeth: Showcasing precision grinding and claw geometry.

Blade Installation: Step-by-step images mounting blades on a TCM shredder rotor.

Material Output: Comparison of processed materials (e.g., uniform plastic flakes, clean metal chips).

Partner with ShengAo: Your Trusted Blade Specialist

ShengAo is a leading manufacturer based in Ma'anshan, China, with over 10 years of experience serving global clients. We offer:

OEM/ODM Services: Custom blades designed for TCM Baler and other shredder brands.

Quality Assurance: ISO 9001 certification, strict quality control, and material traceability.

Fast Delivery: 15-day production time for custom orders, with global shipping via DHL/FedEx.

Technical Support: Free consultation via WhatsApp/Email for blade selection and troubleshooting.

Why Customers Choose Us?

“ShengAo blades doubled the lifespan of our TCM shredder blades, reducing our costs by 40%.” – Recycling Plant, USA

“Excellent compatibility and support. The pre-assembled kits saved us hours of downtime.” – Waste Management Facility, Germany

Explore Related ShengAo Products

Enhance your shredding operation with these complementary products:

Shredder Rotors & Spacers: Precision-machined for balanced performance.

Granulator Blades: For fine grinding after shredding.

Wear-Resistant Liners: Protect shredder chambers from abrasion.

Maintenance Tools: Sharpening equipment and alignment tools.

Conclusion: Upgrade Your TCM Baler Shredder with ShengAo Blades

ShengAo shredder blades are engineered to unlock the full potential of your TCM Baler equipment. With superior materials, custom options, and expert support, we help you achieve higher throughput, lower costs, and uninterrupted operation. Request a free quotation today and experience the ShengAo difference!

Contact Us:

Email: jack@shenaozg.com

Mobile/WhatsApp: +86 152 1234 9604

Website: www.bladesg.com

Subscribe to our newsletter for exclusive tips and offers!