Top5 Shredder Blades with HRC 58-62 Hardness from ShengAo for 3X Longer Lifespan

Top5 Shredder Blades with HRC 58-62 Hardness from ShengAo for 3X Longer Lifespan

Table of Contents

- The Importance of Blade Hardness in Industrial Shredding: Why HRC 58-62 Matters

- Top 5 ShengAo Shredder Blades: The Ultimate Breakdown

- #1: ShengAo Single Shaft Shredder Blades - The All-Rounder

- #2: ShengAo Double Shaft Shredder Blades - The Heavy-Duty Performer

- #3: ShengAo Carbide-Tipped Shredder Blades - The Extreme Wear Fighter

- #4: ShengAo Hardfaced Shredder Blades - The Cost-Effective Warrior

- #5: ShengAo Tungsten Carbide Shredder Blades - The Ultimate Lifespan

- Key Selection Factors: Material, Design, and Customization

- ShengAo Blades Compatibility: Seamless Integration with Leading Shredder Brands

- ShengAo Shredder Blades Comparison Table

- Conclusion: Maximize Your Shredding Efficiency with ShengAo

1. The Importance of Blade Hardness in Industrial Shredding: Why HRC 58-62 Matters

In the demanding world of industrial shredding, blade hardness isn't just a specification—it's the difference between profitability and constant downtime. The Rockwell Hardness Scale (HRC) measures a material's resistance to deformation, and in the context of shredder blades, this translates directly to wear resistance and longevity. An HRC rating of 58-62 represents the sweet spot for industrial shredding applications, providing the perfect balance between hardness for wear resistance and toughness to prevent chipping or catastrophic failure.

When processing challenging materials like metal, e-waste, hard plastics, and wood, standard blades with lower HRC ratings quickly dull, leading to reduced throughput, increased energy consumption, and frequent blade changes. The ShengAo advantage lies in our precision heat treatment processes that consistently achieve HRC 58-62 across our entire product line. This controlled hardness ensures our blades maintain their cutting edge up to three times longer than conventional blades, dramatically reducing your operational costs and maintenance intervals. For operations processing abrasive materials, this hardness range is particularly crucial as it withstands the micro-abrasion that quickly degrades softer blades.

2. Top 5 ShengAo Shredder Blades: The Ultimate Breakdown

After rigorous testing in real-world industrial applications, our engineering team has identified five exceptional shredder blade configurations that deliver outstanding performance across various materials and operational requirements. This comprehensive review is based on cutting efficiency, durability, total cost of ownership, and innovative design features.

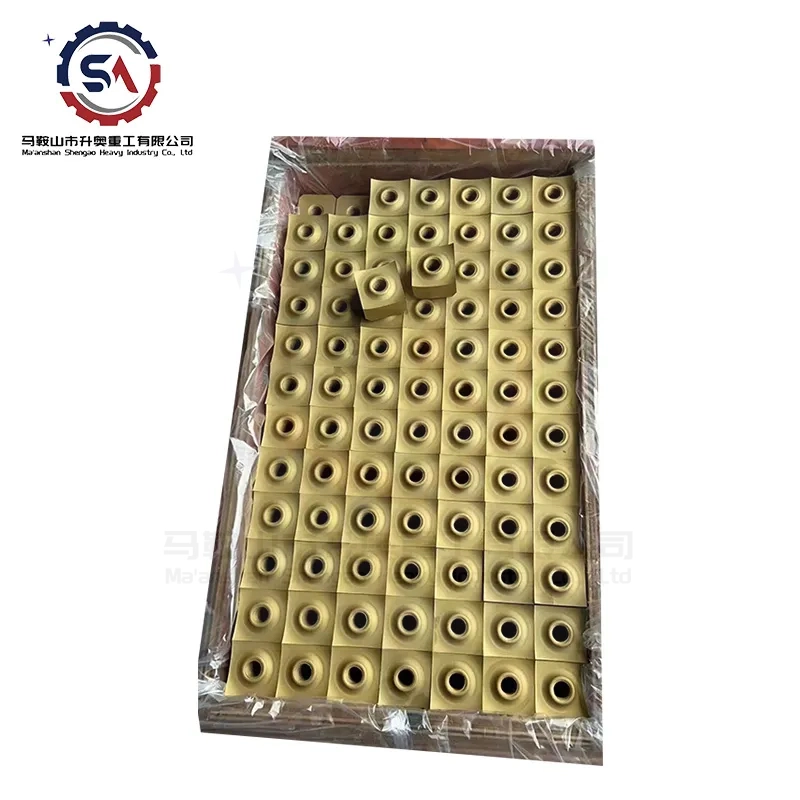

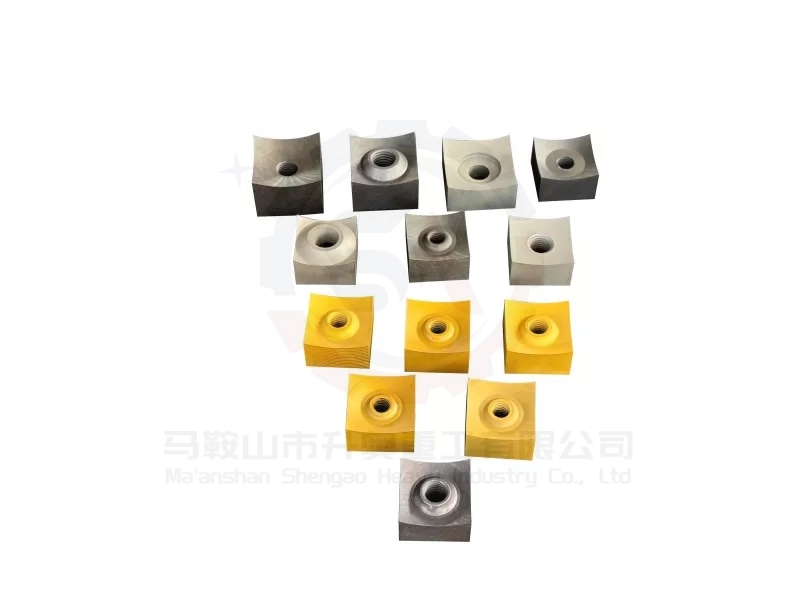

#1: ShengAo Single Shaft Shredder Blades - The All-Rounder

Brand Popularity: ★★★★★

Brand Introduction: As the flagship product from ShengAo, these single shaft shredder blades represent our core expertise and manufacturing excellence. Engineered for versatility, they handle everything from plastic recycling to wood processing and municipal solid waste with exceptional efficiency.

Market Position: The preferred choice for operations requiring high-torque, controlled shredding with consistent output size and minimal maintenance.

Why It's Listed: Unmatched performance in single shaft applications with proprietary heat treatment that ensures consistent HRC 60-62 hardness throughout the blade body.

1. Optimized Hook Angle Design:

Our single shaft blades feature a carefully calculated hook angle that maximizes material grab while minimizing energy consumption. This design creates an aggressive cutting action that pulls material into the cutting chamber efficiently, reducing cycle times and preventing jamming.

2. Reinforced Cutting Edges:

Through specialized forging and heat treatment processes, we create blades with exceptional edge retention. The HRC 60-62 hardness is maintained precisely at the cutting edges where wear occurs most rapidly, while the core maintains necessary toughness to withstand impact loads.

3. Customizable Geometry:

Available in various tooth configurations including hook, flat, and ripper designs to match specific material characteristics. This customization ensures optimal performance whether you're processing film plastics, rigid containers, or composite materials.

>> Click to Explore Industrial Shredder Blades

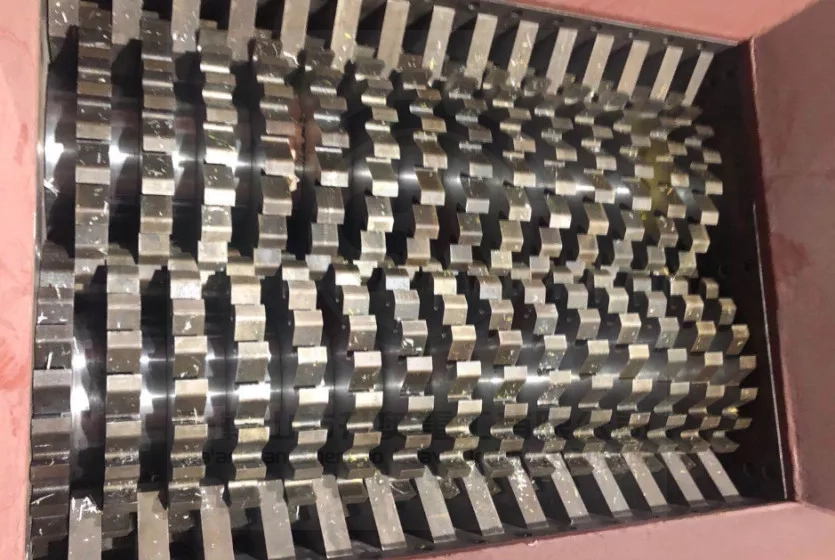

#2: ShengAo Double Shaft Shredder Blades - The Heavy-Duty Performer

Brand Popularity: ★★★★☆

Brand Introduction: Designed for the most demanding dual-shaft shredding applications, these blades deliver exceptional performance in metal processing, e-waste recycling, and tire shredding where shear strength and durability are paramount.

Market Position: The go-to solution for high-volume operations processing abrasive or tough materials that would quickly destroy conventional blades.

Why It's Listed: Superior intermeshing design and balanced hardness profile that provides consistent cutting action while withstanding extreme operational stresses.

1. Precision Intermeshing Technology:

Each blade is manufactured to exacting tolerances ensuring perfect alignment and clearance between opposing rotors. This precision engineering eliminates unnecessary wear points and ensures clean, efficient cutting throughout the blade's lifespan.

2. Multi-Material Compatibility:

Engineered to handle diverse material streams without compromising performance. The optimized hardness (HRC 58-60) provides the perfect balance for processing mixed materials commonly found in e-waste and automotive shredding applications.

3. Enhanced Shear Design:

The scissor-like cutting action of our double shaft blades creates cleaner cuts with less dust generation. This design is particularly beneficial when processing metals and electronics where fine particulate can be problematic.

>> Click to Get Heavy-Duty Double Shaft Blades

#3: ShengAo Carbide-Tipped Shredder Blades - The Extreme Wear Fighter

Brand Popularity: ★★★★★

Brand Introduction: For operations processing highly abrasive materials like fiberglass, carbon fiber, or mineral-filled plastics, our carbide-tipped blades offer unparalleled wear resistance and lifespan extension.

Market Position: The premium solution for applications where standard steel blades fail prematurely due to extreme abrasion.

Why It's Listed: Revolutionary brazing technology that securely bonds tungsten carbide tips to high-strength steel bodies, creating blades that last 5-7 times longer in abrasive applications.

1. Advanced Carbide Formulation:

We utilize specialized tungsten carbide grades specifically formulated for shredding applications. The micro-grain structure provides exceptional hardness (HRC 62+) while maintaining necessary fracture resistance.

2. Proprietary Brazing Process:

Our vacuum brazing technology creates a metallurgical bond between carbide tips and steel bodies that withstands the extreme forces of shredding. This process eliminates the tip loss that plagues conventionally brazed blades.

3. Optimized Tip Geometry:

Each carbide tip is precision-ground to create self-sharpening cutting edges that maintain their sharpness throughout the blade's life. This design significantly reduces power consumption and improves throughput.

>> Click for Carbide-Tipped Shredder Blades

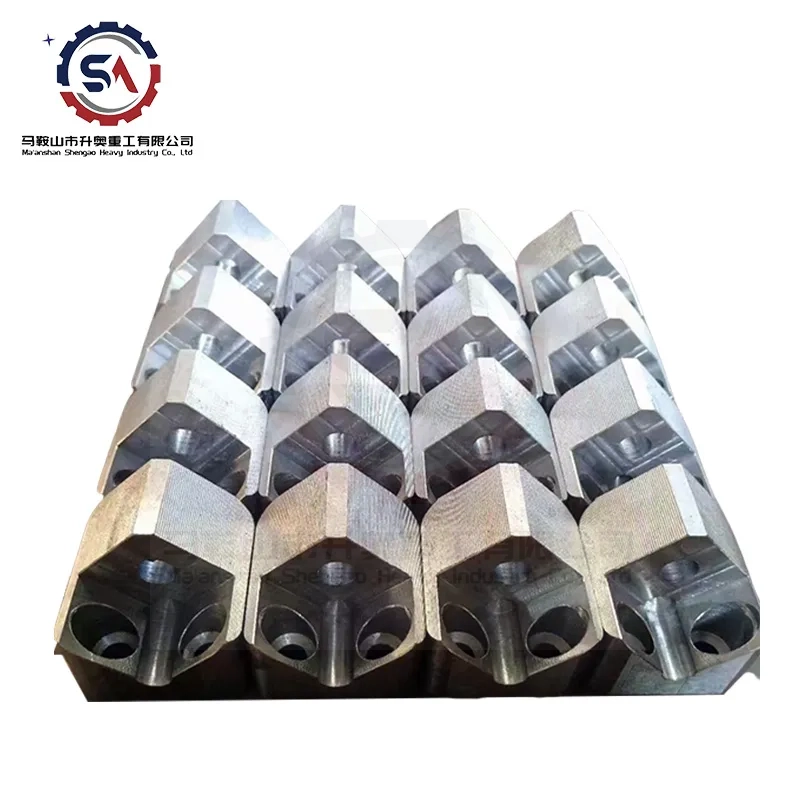

#4: ShengAo Hardfaced Shredder Blades - The Cost-Effective Warrior

Brand Popularity: ★★★★☆

Brand Introduction: Offering exceptional value for operations processing moderately abrasive materials, our hardfaced blades provide enhanced wear resistance at a more accessible price point than full carbide solutions.

Market Position: The smart choice for operations seeking to extend blade life without the premium investment of carbide-tipped options.

Why It's Listed: Advanced hardfacing technology that applies wear-resistant alloys to critical areas, tripling blade life in abrasive applications.

1. Precision Hardfacing Application:

Using automated welding systems, we apply chromium-carbide and tungsten-carbide composites precisely to the cutting edges and high-wear areas. This targeted approach maximizes wear resistance where it's needed most.

2. Multi-Layer Protection:

Our hardfacing process builds up multiple layers of wear-resistant material, creating a composite structure that gradually exposes fresh cutting surfaces as the blade wears. This design significantly extends operational life between sharpenings.

3. Cost-Per-Cut Optimization:

By focusing wear-resistant materials only where needed, we create blades that deliver 80% of the performance of full carbide solutions at approximately 40% of the cost, providing outstanding value for many applications.

>> Click to Power Through with Hardfaced Shredder Blades

#5: ShengAo Tungsten Carbide Shredder Blades - The Ultimate Lifespan

Brand Popularity: ★★★★☆

Brand Introduction: Representing the pinnacle of shredder blade technology, our solid tungsten carbide blades are engineered for the most extreme applications where maximum lifespan and minimal downtime are critical.

Market Position: The ultimate solution for processing highly abrasive materials like fiber-reinforced composites, mineral wool, and filled plastics.

Why It's Listed: Unmatched wear resistance with hardness ratings exceeding HRC 85, providing service life that can be 10 times longer than premium steel blades in extreme applications.

1. Solid Carbide Construction:

Unlike tipped blades, our solid carbide blades are manufactured from premium tungsten carbide blanks, providing consistent hardness and wear resistance throughout the entire blade structure.

2. Extreme Hardness Profile:

With hardness ratings between HRC 85-92, these blades laugh in the face of materials that would destroy conventional steel blades in hours. This extreme hardness comes with carefully engineered toughness to prevent chipping.

3. Specialized Geometry for Brittle Materials:

The cutting geometry is optimized for the unique properties of carbide, creating efficient cutting action while managing the inherent brittleness of these ultra-hard materials. Special relief angles and edge preparations maximize impact resistance.

>> Click for Ultimate Lifespan Carbide Blades

3. Key Selection Factors: Material, Design, and Customization

Choosing the right shredder blade involves more than just selecting the hardest option available. Understanding these critical factors will ensure you select blades that deliver optimal performance and value for your specific application.

Material Composition:

- D2 Tool Steel: Excellent all-around choice with good wear resistance and toughness. Ideal for general-purpose shredding of plastics, wood, and non-ferrous metals.

- H13 Hot Work Steel: Superior thermal stability makes it perfect for applications where friction heat is a concern. Maintains hardness at elevated temperatures.

- 420 Stainless Steel: Corrosion-resistant option for processing wet materials or in humid environments. Essential for food processing or medical waste applications.

- Tungsten Carbide: The ultimate in wear resistance for highly abrasive materials. Available as solid construction or as tips brazed to steel bodies.

Blade Design Elements:

- Tooth Geometry: Hook teeth for aggressive feeding, flat teeth for shearing action, or ripper teeth for tearing fibrous materials.

- Cutting Angle: The angle between the cutting face and material being processed affects both cutting efficiency and blade life.

- Clearance Angles: Proper clearance prevents rubbing and reduces heat buildup, extending blade life and reducing power consumption.

Customization Options:

At ShengAo, we understand that off-the-shelf solutions rarely deliver optimal performance. Our engineering team works directly with customers to develop custom blade configurations tailored to specific materials, machine types, and operational requirements. From specialized heat treatment protocols to unique tooth geometries, we create Wear-resistant shredder blades that solve your specific challenges.

4. ShengAo Blades Compatibility: Seamless Integration with Leading Shredder Brands

One of the significant advantages of choosing ShengAo shredder blades is our extensive compatibility with leading shredder manufacturers worldwide. Our engineering team has reverse-engineered and improved upon OEM designs to create blades that not only fit perfectly but often outperform original equipment.

Metso: Our blades are precision-engineered to match Metso's exacting specifications for their Lindemann and Texas Shredder lines. The improved wear characteristics of our HRC 58-62 blades typically deliver 30-50% longer life in identical applications.

Vecoplan: For Vecoplan single and dual-shaft shredders, we offer both standard replacement blades and custom-engineered solutions for challenging materials. Our blades maintain the precise tolerances required for Vecoplan's high-performance systems.

UNTHA: Compatible with UNTHA's sophisticated shredding technology, our blades are engineered to work seamlessly with their precision cutting systems. The consistent hardness profile ensures reliable performance throughout the blade's life.

WEIMA: Our shredder blade solutions for WEIMA machines include specialized configurations for their unique cutting geometries. We've developed particular expertise in blades for their WLK and WNZ series.

Genox Recycling: For Genox's comprehensive recycling systems, we provide blades that enhance rather than simply replace OEM performance. Our technical team understands the specific requirements of Genox's engineered cutting systems.

Harden Machinery: As a leading Chinese manufacturer, Harden's shredders benefit from our localized engineering support and rapid response customization services. We maintain comprehensive specifications for their entire product range.

GEP ECOTECH: Our collaboration with GEP ECOTECH has resulted in several custom blade developments specifically for their advanced shredding systems. We understand the performance requirements of their sophisticated cutting technology.

Maxin India Machinery: For the challenging conditions often encountered in Indian recycling operations, we've developed reinforced blade configurations that withstand the unique material streams and operational patterns.

Hammel: Compatible with Hammel's powerful primary and secondary shredders, our blades are engineered to handle the extreme forces generated by their high-torque systems while maintaining cutting precision.

Arjes: For Arjes' innovative slow-speed, high-torque shredders, we provide blades optimized for their unique cutting action. The controlled hardness profile ensures clean cutting with minimal dust generation.

Stiler: Our comprehensive understanding of Stiler's engineering principles allows us to provide blades that integrate perfectly with their systems while offering enhanced wear characteristics.

Olnova: For Olnova's specialized shredding solutions, we offer both standard replacements and custom-engineered blades designed for their specific applications and material challenges.

5. ShengAo Shredder Blades Comparison Table

| Blade Model | Best For | Hardness (HRC) | Expected Life Extension | Key Feature |

|---|---|---|---|---|

| ShengAo Single Shaft | Plastic, Wood, MSW | 60-62 | 3X | Optimized Hook Angle |

| ShengAo Double Shaft | Metal, E-Waste, Tires | 58-60 | 2.5X | Precision Intermeshing |

| ShengAo Carbide-Tipped | Abrasive Composites, Minerals | 62+ (tips) | 5-7X | Brazed Tungsten Carbide Tips |

| ShengAo Hardfaced | Moderately Abrasive Materials | 58-65 (surface) | 3X | Precision Hardfacing |

| ShengAo Solid Carbide | Extreme Abrasion Applications | 85-92 | 10X+ | Solid Tungsten Carbide |

6. Conclusion: Maximize Your Shredding Efficiency with ShengAo

The "best" shredder blade is ultimately determined by your specific material stream, operational requirements, and economic considerations. However, the ShengAo blades featured in this comprehensive review represent the pinnacle of current shredding technology across the most common industrial applications.

For general recycling operations processing plastics, wood, and MSW: The #1 ShengAo Single Shaft Shredder Blades deliver exceptional performance and value, with their optimized hook angle and consistent HRC 60-62 hardness.

For metal processing, e-waste, and tire recycling: The #2 ShengAo Double Shaft Shredder Blades provide the perfect balance of hardness and toughness needed for these demanding applications.

For extreme abrasive applications like composites and mineral-filled materials: The #3 ShengAo Carbide-Tipped Shredder Blades or #5 ShengAo Solid Carbide Blades offer revolutionary lifespan extension that can transform your operational economics.

Investing in the right shredder blades is one of the most impactful decisions you can make for your operation's productivity and profitability. Don't let inferior blades be the bottleneck in your recycling or size reduction process. Explore the full range of engineering excellence from ShengAo, a brand committed to providing durable, high-performance cutting solutions that reduce your downtime and maintenance costs.

For our international partners, discover more about our products in your language: 産業用シュレッダーブレード (Japanese) and Промышленные ножи для шредеров (Russian).