Top 5 Customizable Features of ShengAo Shredder Blades for Perfect Compatibility

Top 5 Customizable Features of ShengAo Shredder Blades for Perfect Compatibility

Table of Contents

- The Evolution of Shredder Blade Technology in 2025

- Top 5 Customizable Features of ShengAo Shredder Blades

- ShengAo Blade Compatibility: Custom Fit for Major Shredder Brands

- Material-Specific Customization: E-Waste vs Metal Recycling

- The ShengAo Customization Process: From Design to Delivery

- Conclusion & Final Recommendations

1. The Evolution of Shredder Blade Technology in 2025

The industrial shredding industry has reached a pivotal moment in 2025, where off-the-shelf, one-size-fits-all shredder blades no longer meet the demanding requirements of modern recycling operations. With material streams becoming more complex and contamination levels increasing, the need for precisely engineered, custom-tailored shredder blades has never been more critical. The evolution has shifted from standardized blade production to sophisticated customization that addresses specific material characteristics, machine parameters, and operational goals.

At the forefront of this revolution is ShengAo, a manufacturer that has built its reputation on deep customization capabilities. Unlike conventional blade suppliers who offer limited options, ShengAo approaches each project as a unique engineering challenge. Their philosophy centers on the understanding that optimal shredding performance comes from perfect compatibility between the blade and its intended application—whether that's processing delicate electronic waste with embedded precious metals or tackling tough metal scrap with high tensile strength.

The technological advancements in metallurgy, precision manufacturing, and application engineering have enabled ShengAo to deliver blades that not only fit perfectly but perform exceptionally in their specific roles. This article explores the five key customizable features that set ShengAo shredder blades apart and ensure perfect compatibility with your shredding operations.

2. Top 5 Customizable Features of ShengAo Shredder Blades

Customization is at the heart of ShengAo's manufacturing philosophy. Through extensive research and development, they have identified five critical areas where precise customization can dramatically impact shredding performance, operational costs, and overall efficiency. Each feature represents an opportunity to optimize the blade for specific materials, machine types, and production goals.

#1: Steel Material Selection for Specific Applications

Customization Impact: ★★★★★

Feature Overview: The foundation of any high-performance shredder blade begins with selecting the appropriate steel material. ShengAo offers an extensive portfolio of steel grades, each engineered for specific material types and operational conditions. This goes beyond simple material choice to include custom alloy compositions and specialized steel treatments.

Why It Matters: Using the wrong steel grade for your application can lead to premature wear, chipping, catastrophic failure, or inefficient shredding. The correct steel selection ensures optimal performance, longer service life, and reduced operational costs.

Customization Options:

D2 Tool Steel - The All-Rounder: Ideal for general-purpose shredding of plastics, wood, and non-ferrous materials. ShengAo's D2 formulation offers exceptional wear resistance with good toughness, making it suitable for most single-shaft shredder applications. The high chromium content provides corrosion resistance, while the carbon content ensures edge retention.

H13 Hot Work Steel - For High-Temperature Applications: Specifically engineered for applications where heat generation is significant. H13 maintains its hardness and strength at elevated temperatures, making it perfect for continuous operations processing materials that generate friction heat. This is particularly valuable for plastic shredder blades in high-volume operations.

Tungsten Carbide Solutions - Extreme Abrasion Resistance: For the most challenging materials like fiberglass, electronic waste, and highly abrasive composites, ShengAo offers tungsten carbide tipped blades and full-carbide options. These solutions can extend blade life by 5-8 times compared to standard tool steels in abrasive applications.

Special Alloy Steels - Impact & Toughness Focused: For applications involving unexpected impacts or tramp metal, ShengAo develops custom alloy steels that prioritize toughness over pure hardness. These steels are engineered to withstand shock loading without catastrophic failure.

>> Explore Custom Steel Options for Your Application

#2: Blade Geometry & Claw Design Optimization

Customization Impact: ★★★★★

Feature Overview: Blade geometry directly influences cutting efficiency, material feeding, energy consumption, and output size. ShengAo's engineering team works closely with clients to optimize every aspect of blade geometry, from hook angles and claw designs to clearance angles and edge preparation.

Why It Matters: The wrong geometry can cause poor material feeding, increased energy consumption, inconsistent output size, and premature wear. Optimized geometry ensures efficient operation and consistent performance.

Customization Options:

Hook Angle Optimization: ShengAo engineers calculate the ideal hook angle based on material characteristics. Steeper angles provide more aggressive feeding for elastic materials like rubber and plastic film, while shallower angles offer controlled cutting for brittle materials. This is particularly critical for single shaft shredder blades where feeding efficiency directly impacts throughput.

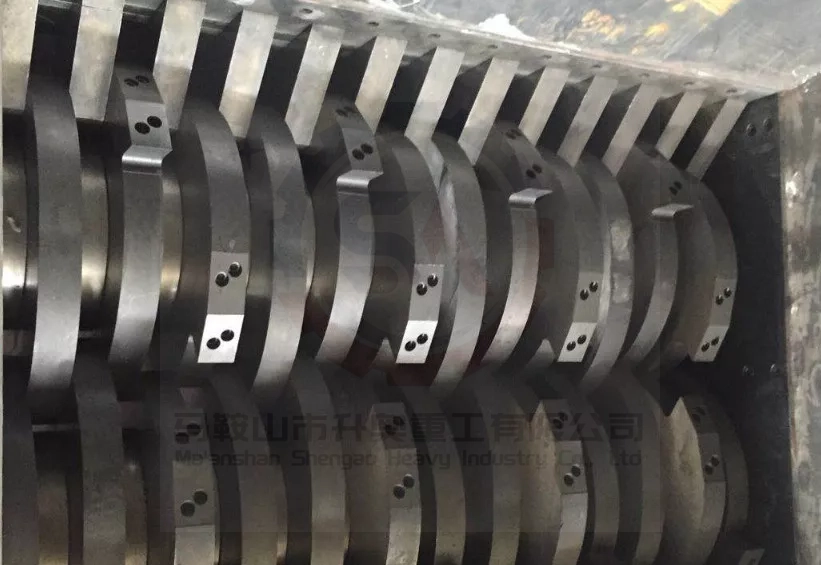

Claw Design & Configuration: For dual-shaft applications, claw design determines the shearing action and material reduction efficiency. ShengAo offers various claw patterns, including standard, spiral, and specialized configurations for specific materials. The intermeshing design can be optimized for maximum shear force or controlled tearing action.

Edge Geometry & Sharpness: Depending on the application, ShengAo customizes edge geometry from razor-sharp for clean cutting to reinforced for impact resistance. Edge preparation includes specialized treatments to enhance durability and maintain sharpness.

Clearance Angles & Relief Grinding: Proper clearance angles prevent material wedging and reduce friction. ShengAo optimizes these angles based on material flow characteristics and desired output size distribution.

>> Discover Optimized Geometry for Your Material

#3: Hardness & Heat Treatment Customization

Customization Impact: ★★★★☆

Feature Overview: Hardness is not a one-size-fits-all parameter in shredder blades. ShengAo customizes both surface hardness and core hardness through precise heat treatment processes tailored to specific applications. This includes specialized treatments like cryogenic processing and tempering cycles optimized for different steel types.

Why It Matters: Incorrect hardness can lead to rapid wear (if too soft) or chipping and catastrophic failure (if too hard). The ideal hardness balances wear resistance with necessary toughness for the application.

Customization Options:

Application-Specific Hardness Ranges: ShengAo tailors hardness to specific materials: HRC 58-62 for clean plastics and wood, HRC 55-58 for general-purpose applications with some contamination, and HRC 50-55 for high-impact applications with tramp metal risk. This high hardness blade approach ensures optimal performance in each scenario.

Differential Hardness Treatment: For some applications, ShengAo implements differential hardening where the cutting edge receives higher hardness than the blade body, providing both extreme wear resistance and shock absorption.

Core Toughness Optimization: While surface hardness resists wear, core toughness prevents catastrophic failure. ShengAo customizes the heat treatment process to create blades with hard surfaces and tough cores, ideal for applications with occasional impacts.

Specialized Heat Treatment Cycles: Beyond standard hardening and tempering, ShengAo offers specialized treatments like multiple tempering cycles for stress relief, cryogenic treatment for enhanced dimensional stability, and surface treatments for specific material compatibility.

>> Learn About Custom Hardness Solutions

#4: Size & Dimension Precision Engineering

Customization Impact: ★★★★☆

Feature Overview: Perfect physical compatibility with existing shredder equipment is non-negotiable for optimal performance. ShengAo specializes in reverse engineering and custom dimensioning to ensure blades fit precisely in OEM equipment or custom shredder designs.

Why It Matters: Improperly sized blades cause vibration, reduced efficiency, premature bearing failure, and potential safety hazards. Perfect dimensional compatibility ensures smooth operation and maximum power transfer.

Customization Options:

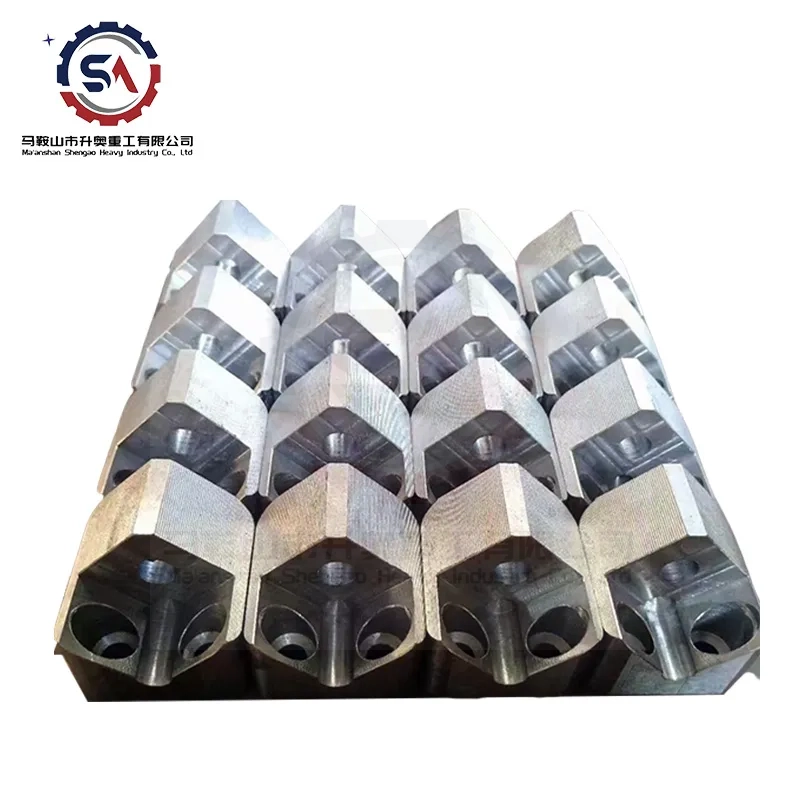

Bore Size & Tolerance Engineering: ShengAo precisely machines bore sizes with tolerances as tight as ±0.01mm to ensure perfect fit on shredder rotors. Custom keyway configurations, splined bores, and specialized mounting systems are available for unique applications.

Blade Thickness & Width Optimization: Blade dimensions are optimized based on the shredder's power, material type, and desired throughput. Thicker blades provide more mass for momentum in heavy-duty applications, while optimized width affects cutting chamber density and efficiency.

Overall Geometry & Mounting Configuration: From standard rectangular designs to specialized shapes for unique shredder configurations, ShengAo engineers blades to match exact equipment requirements. This includes custom corner radii, chamfers, and mounting hole patterns.

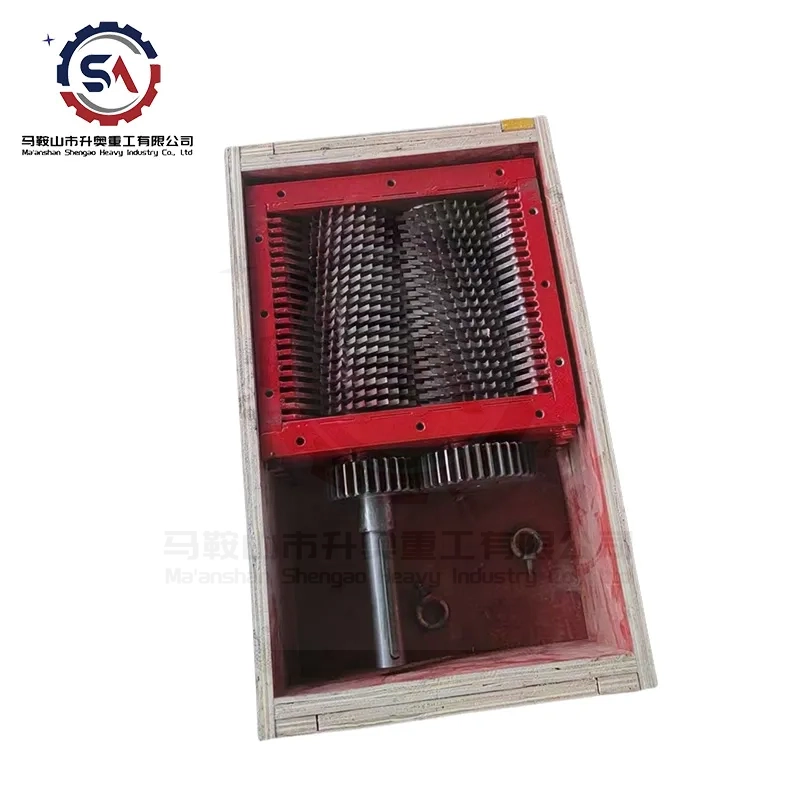

Rotor System Integration: For complete compatibility, ShengAo can engineer blades as part of an integrated rotor system, ensuring perfect balance and optimal performance across the entire cutting assembly.

>> Get Perfectly Sized Blades for Your Equipment

#5: Surface Coating & Special Treatments

Customization Impact: ★★★★☆

Feature Overview: Advanced surface treatments and coatings can dramatically enhance blade performance in specific applications. ShengAo offers a range of coating technologies and surface treatments that reduce friction, enhance wear resistance, prevent material adhesion, and provide corrosion protection.

Why It Matters: Specialized coatings can extend blade life by 30-300% depending on the application, reduce energy consumption, improve material flow, and prevent problematic material buildup on cutting surfaces.

Customization Options:

Wear-Resistant Coatings: Titanium Nitride (TiN), Titanium Carbonitride (TiCN), and Chromium Nitride (CrN) coatings significantly enhance surface hardness and reduce friction. These are particularly valuable for double shaft shredder blades processing abrasive materials.

Non-Stick Surface Treatments: For materials that tend to adhere to cutting surfaces (certain plastics, sticky materials), ShengAo applies specialized non-stick treatments that prevent buildup and maintain cutting efficiency.

Corrosion Protection Systems: For applications involving moist materials, saltwater environments, or corrosive chemicals, ShengAo implements corrosion-resistant coatings and treatments that protect both the cutting edges and structural integrity of the blades.

Hybrid Treatment Systems: Combining multiple surface technologies for maximum performance in challenging applications. This might include hardening treatments followed by specialized coatings for both wear resistance and non-stick properties.

>> Explore Performance-Enhancing Coatings

3. ShengAo Blade Compatibility: Custom Fit for Major Shredder Brands

One of the most significant advantages of ShengAo's customization capabilities is the ability to engineer perfect compatibility with major shredder brands worldwide. Unlike generic replacement blades that claim "universal fit," ShengAo blades are precision-engineered to match OEM specifications or exceed them with performance enhancements. Our reverse engineering process ensures dimensional accuracy while our material science expertise often delivers superior performance compared to original blades.

Metso

ShengAo provides custom-engineered blades compatible with Metso's robust shredding systems, including the Pri-Max primary shredders. Our blades are optimized to handle the high-torque requirements and shock loads typical in Metso equipment, with material selections specifically chosen for mining, recycling, and aggregate applications. The customization includes precise bore sizing, specialized hardness profiles, and geometry optimized for Metso's unique cutting chamber designs.

Vecoplan

As pioneers in single-shaft shredding technology, Vecoplan machines demand precision engineering. ShengAo's single-shaft blades are meticulously crafted to match or exceed OEM specifications for Vecoplan's VAZ, VEZ, and VHZ series. Our customization process includes detailed analysis of Vecoplan's rotor designs, material flow patterns, and performance requirements to deliver blades that maintain the high efficiency Vecoplan users expect.

UNTHA

For UNTHA's precision engineering standards, ShengAo offers compatible blades that deliver the reliability and cutting accuracy these machines are known for. Our customization includes specific geometry for UNTHA's unique cutting systems, specialized hardness ranges for different material streams, and dimensional precision that ensures perfect integration with UNTHA's advanced monitoring and control systems.

WEIMA

ShengAo blades are engineered for perfect compatibility with WEIMA's extensive range of shredders. Whether it's a single-shaft machine for bulky waste or a four-shaft shredder for fine granulation, we provide durable, high-performance blades that integrate seamlessly. Our customization process addresses WEIMA's specific mounting systems, rotor configurations, and application requirements across their product line.

Genox Recycling

We supply custom blades for Genox recycling equipment, known for processing challenging materials like e-waste and mixed plastics. Our blades offer the toughness and wear resistance needed to handle embedded metals and abrasive composites. Customization includes specialized steel selections for Genox's high-speed applications, optimized geometry for their cutting chamber designs, and specific hardness profiles for their diverse material streams.

Harden Machinery

ShengAo is a trusted partner for Harden Machinery shredder owners. Our blades are engineered to fit Harden's robust designs perfectly, providing an excellent balance of sharpness and durability for recycling various plastic and rubber materials. Customization includes precise dimensional matching, material selections optimized for Harden's applications, and specialized heat treatments for their operating conditions.

GEP ECOTECH

Compatible with GEP ECOTECH's innovative shredders, our blades are built to uphold the high efficiency and intelligence of these systems. We provide reliable cutting solutions that ensure consistent output size and reduced maintenance. Customization includes integration with GEP's smart monitoring systems, specialized geometries for their cutting technology, and material selections that match their application focus.

Maxin India Machinery

For Maxin India's shredders, often used in organic waste and fertilizer production, ShengAo offers corrosion-resistant and durable blades that withstand the moist and chemically active environment, ensuring long service life. Customization includes specialized stainless steel options, non-stick coatings for organic materials, and geometry optimized for their specific rotor designs.

Hammel

ShengAo's heavy-duty blades are engineered to meet the demands of HAMMEL primary and secondary shredders. Our solutions are ideal for processing C&D waste, scrap metal, and logs, offering superior impact resistance. Customization includes specialized claw designs for HAMMEL's dual-shaft systems, impact-resistant steel selections, and hardness profiles optimized for their high-torque applications.

Arjes

We provide compatible blades for ARJES shredders, known for their versatility. Our blades help maintain the high performance and slow-speed, high-torque efficiency that ARJES machines are renowned for in processing wood, green waste, and mixed materials. Customization includes geometry optimized for their unique cutting systems, specialized steel for their application range, and precise dimensional matching.

Stiler

ShengAo manufactures custom-fit blades for Stiler shredders, ensuring they deliver reliable performance in recycling applications. Our focus on material quality translates to longer intervals between sharpening and replacements. Customization includes precise dimensional engineering for Stiler's rotor systems, specialized heat treatments for their operating conditions, and geometry optimized for their specific applications.

Olnova

For Olnova's plastic recycling and pelletizing lines, ShengAo offers precision blades that ensure clean cuts and high throughput, contributing to the overall efficiency of the recycling process. Customization includes specialized geometries for Olnova's granulator designs, optimized clearances for their cutting systems, and material selections that match their processing requirements.

4. Material-Specific Customization: E-Waste vs Metal Recycling

The true value of ShengAo's customization capabilities becomes most apparent when addressing vastly different material streams. Electronic waste (e-waste) and metal scrap represent two extremes in the recycling industry, each demanding unique blade characteristics for optimal processing.

E-Waste Shredding Customization:

Electronic waste presents unique challenges with its combination of brittle components (circuit boards), flexible materials (wires and cables), and embedded metals. ShengAo's customization for e-waste focuses on several key areas:

Abrasion Resistance Priority: Circuit boards contain fiberglass and ceramics that are highly abrasive. ShengAo typically recommends tungsten carbide tipped blades or specialized tool steels with enhanced wear resistance. The customization includes specific carbide grades optimized for the silica content in fiberglass.

Controlled Fracture Geometry: Blade geometry is optimized to create controlled fracture in brittle materials while efficiently shearing flexible components. This often involves specialized hook angles and clearance configurations that prevent wrapping of wires while effectively breaking circuit boards.

Corrosion Protection: E-waste often contains batteries and chemical components that can cause corrosion. ShengAo implements specialized coatings and material selections that resist chemical attack from battery acids and other corrosive elements.

Size Reduction Optimization: For e-waste destined for material separation, precise particle size is critical. ShengAo customizes blade geometry and rotor configurations to achieve the optimal size distribution for downstream separation processes.

Metal Recycling Customization:

Metal scrap shredding demands completely different characteristics, focusing on impact resistance and toughness rather than pure abrasion resistance:

Shock Absorption Design: Metal scrap often contains unexpected hard spots and tramp materials. ShengAo customizes blades with enhanced toughness through specialized steel selections and heat treatment processes that prioritize impact resistance over maximum hardness.

Shear-Optimized Geometry: Metal shredding relies more on shearing action than impact fracture. ShengAo engineers specialized claw geometries and hook angles that maximize shear force while minimizing energy consumption.

Mass & Momentum Considerations: For heavy metal scrap, blade mass becomes a critical factor. ShengAo customizes blade dimensions and weights to provide optimal momentum for efficient size reduction of dense materials.

Heat Management: Metal shredding generates significant heat. ShengAo implements specialized heat treatments and sometimes cooling features to maintain blade integrity under high-temperature conditions.

5. The ShengAo Customization Process: From Design to Delivery

ShengAo's customization approach follows a systematic process that ensures every blade is perfectly tailored to its intended application. This comprehensive methodology distinguishes true customization from simple modification and guarantees optimal performance.

Phase 1: Application Analysis & Requirements Definition

The process begins with deep understanding of the customer's specific needs. ShengAo's technical team conducts detailed analysis of:

- Material characteristics (composition, hardness, abrasiveness, moisture content)

- Machine specifications (power, rotor design, operating parameters)

- Operational goals (throughput, output size, efficiency targets)

- Environmental factors (operating temperature, contamination risks)

- Economic objectives (cost-per-ton targets, service life expectations)

Phase 2: Engineering & Design Customization

Based on the application analysis, ShengAo engineers develop customized solutions addressing all five key features:

- Material Selection: Choosing the optimal steel grade or composite material

- Geometry Design: Engineering blade shape, angles, and features

- Hardness Profile: Defining surface and core hardness requirements

- Dimensional Specification: Precise sizing for perfect equipment fit

- Surface Treatment: Selecting coatings or treatments for enhanced performance

Phase 3: Prototyping & Validation

For critical applications or new configurations, ShengAo often creates prototypes for testing and validation. This phase may include:

- Laboratory testing for material properties and wear characteristics

- Field testing in actual operating conditions

- Performance measurement against established benchmarks

- Iterative refinement based on test results

Phase 4: Precision Manufacturing

Once the design is finalized, ShengAo employs advanced manufacturing techniques to produce the customized blades:

- CNC machining for dimensional precision

- Controlled atmosphere heat treatment for consistent properties

- Specialized grinding and finishing for optimal cutting edges

- Quality verification at every manufacturing step

Phase 5: Performance Monitoring & Continuous Improvement

ShengAo maintains ongoing relationships with customers to monitor blade performance and identify opportunities for further optimization. This commitment to continuous improvement ensures that blades evolve alongside changing operational requirements.

6. Conclusion & Final Recommendations

In the evolving landscape of industrial shredding, customization has transitioned from luxury to necessity. The five customizable features offered by ShengAo—steel material selection, blade geometry design, hardness treatment, dimensional precision, and surface coatings—represent the comprehensive approach needed to achieve perfect compatibility in today's demanding recycling environments.

The ability to tailor every aspect of shredder blade performance to specific materials, equipment, and operational goals delivers tangible benefits that directly impact profitability and efficiency. Whether processing delicate electronic waste with embedded valuable materials or tackling tough metal scrap with high tensile strength, ShengAo's customization capabilities ensure optimal performance where it matters most.

For operations seeking to maximize efficiency and reduce operational costs: Focus on comprehensive customization that addresses all five key features rather than partial solutions. The synergistic effect of coordinated customization across material, geometry, hardness, dimensions, and surface treatments delivers performance gains that exceed the sum of individual improvements.

For facilities processing multiple material streams: Consider developing specialized blade sets for different materials rather than compromising with general-purpose blades. The investment in multiple customized blade configurations typically pays for itself through increased throughput, reduced downtime, and extended service life.

For operations using specialized or older equipment: Take advantage of ShengAo's reverse engineering capabilities to create perfect compatibility solutions. The precision dimensional customization ensures optimal performance even for equipment where OEM blades are no longer available or underperforming.

The future of shredding efficiency lies in blades engineered not just for cutting, but for perfect compatibility with specific materials, machines, and operational goals. ShengAo's commitment to deep customization across these five critical features represents the cutting edge of this approach, delivering performance improvements that translate directly to enhanced profitability and operational excellence.