Single Shaft Shredder Blades

ShengAo Single Shaft Shredder Blades: Engineered for high-efficiency size reduction in plastic recycling, wood processing, e-waste disposal, and general industrial waste management. These blades ensure durable performance and reduced downtime for single-shaft shredding systems.

√ High-Wear Material Options: Manufactured from tool steels like Cr12MoV, D2, or SKD11 with standard hardness of HRC 58-62. Optional carbide tips available for highly abrasive materials.

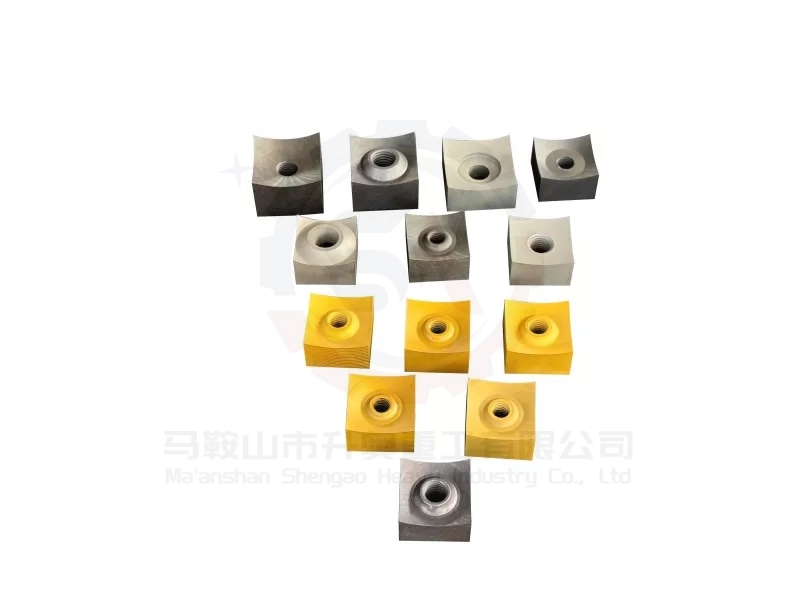

√ Optimized Blade Design: Square-shaped moving blades with four cutting edges, curved design, and center-tapped holes for smooth cooperation with fixed blades, enabling efficient shredding of plastics, wood, rubber, and cables.

√ Enhanced Durability & Easy Maintenance: Excellent wear and impact resistance with optional titanium or chrome coatings to reduce friction and corrosion. Simple structure allows for easy replacement and minimal downtime.

√ Customization & Versatility: Available in standard sizes (e.g., 40x40x25mm, 60x60x30mm) or custom dimensions. Suitable for shredding plastic films, pipes, woven bags, wood pallets, scrap metals, and e-waste.

√ SEO-Friendly Keywords: Single shaft shredder blades, plastic recycling blades, industrial shredder knives, Cr12MoV blades, wear-resistant shredder blades, OEM shredder blades, wood and metal waste recycling blades.

Request Our Latest Price

.webp)