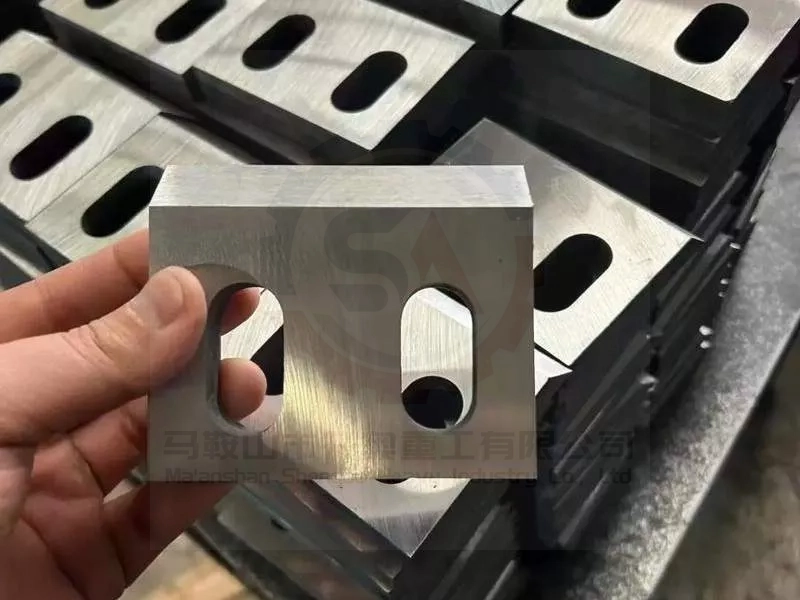

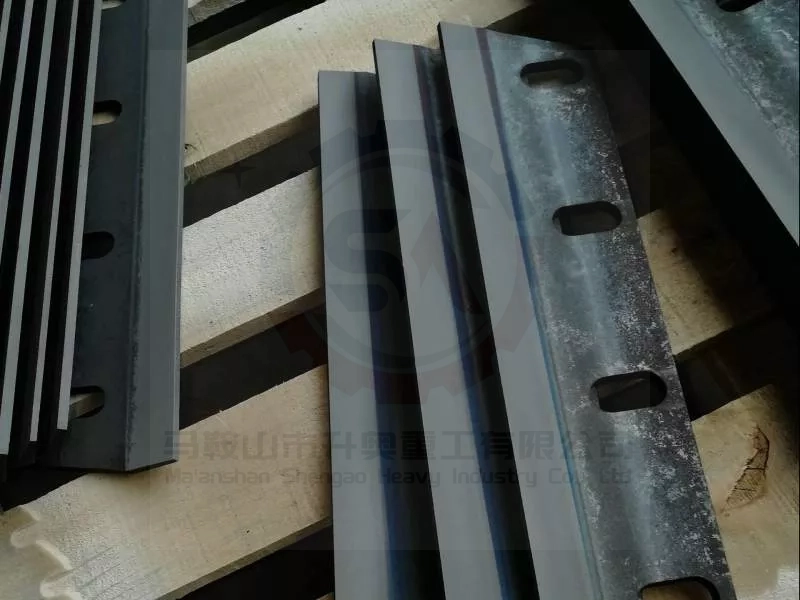

Precision Engineered for Plastic Recycling

Our professional-grade crusher blades are engineered for exceptional performance in plastic recycling applications, specifically designed to handle ABS, PE, PP, and other common polymers with unmatched efficiency. Each blade is manufactured with precision engineering to deliver superior cutting performance and extended operational life. Key technological advantages include:

Advanced Material Composition: Utilizing high-carbon steel and tool steel formulations that provide exceptional hardness and wear resistance, specifically engineered for continuous shredding of abrasive plastic materials without compromising cutting sharpness.

Precision Heat Treatment: Vacuum heat treatment and deep cooling processes enhance blade microstructure, achieving optimal hardness (HRC 58-62) while maintaining necessary toughness to prevent chipping and breakage under heavy loads.

Customized Blade Geometries: Tailored blade designs including slice blades, flat blades, and V-blades optimized for different plastic types and processing requirements, ensuring clean cuts and reduced energy consumption.

Enhanced Wear Resistance: Specialized coatings and surface treatments including titanium nitride (TiN) provide exceptional protection against abrasive wear, extending service intervals and reducing maintenance downtime by up to 40%.

Application-Specific Engineering: Blades are precision-balanced for high-speed operation in various crusher configurations, including single-shaft and multi-shaft systems, with optimized tooth configurations for different material throughput requirements.