How Do You Match Shredder Blades to Your Specific Application?For plastics, wood, metal, and waste r

How Do You Match Shredder Blades to Your Specific Application?

1. Table of Contents

- The Critical Role of the Right Shredder Blade

- Single-Shaft vs. Dual-Shaft Shredders: Choosing the Right Blade System

- Key Factors for Matching Blades to Your Application

- ShengAo Expertise: Engineering Blades for Every Scenario

- Universal Compatibility: ShengAo Blades for Major Shredder Brands

- Conclusion: Partner with ShengAo for Unmatched Performance

The Critical Role of the Right Shredder Blade

In the world of size reduction and recycling, the shredder is only as effective as the blades that power it. Selecting the correct blades for recycling is not a matter of guesswork; it is a precise science that directly impacts your operational efficiency, product quality, maintenance costs, and overall profitability. A mismatched blade can lead to premature wear, frequent downtime, high energy consumption, and an inconsistent output that fails to meet market specifications. This ultimate guide will demystify the process, providing you with the knowledge to perfectly match Industrial Shredder Blades to your specific application, ensuring you unlock maximum productivity and value from your machinery.

Single-Shaft vs. Dual-Shaft Shredders: Choosing the Right Blade System

Before diving into material-specific blades, it's crucial to understand the two primary shredder technologies: single-shaft and dual-shaft. Each employs a distinct cutting action and requires a specific blade design.

Single-Shaft Shredder Blades: The Powerhouse for Tough Materials

Single-shaft shredders feature a robust, slow-turning rotor with blades that work in conjunction with a stationary bed blade. The action is a powerful "tear and shear" process, ideal for voluminous, tough, and stringy materials. The shredder blades for single shaft machine are typically designed as hooks, claws, or diamonds that grab, tear, and pull the material through the screen. At ShengAo, our expertise shines brightest in this category. We engineer our single-shaft blades for exceptional durability and cutting force, making them the go-to choice for:

- Large, bulky waste

- Tough plastics and purgings

- Tires and rubber

- Metal drums and non-ferrous scrap

- Wood pallets and demolition lumber

The key to a high-performance single-shaft blade lies in its geometry, hardness, and the quality of the steel. Our blades are precision-engineered to create an aggressive grip and a clean shear, reducing energy consumption and preventing material wrapping.

Dual-Shaft Shredder Blades: The Efficient Shearers

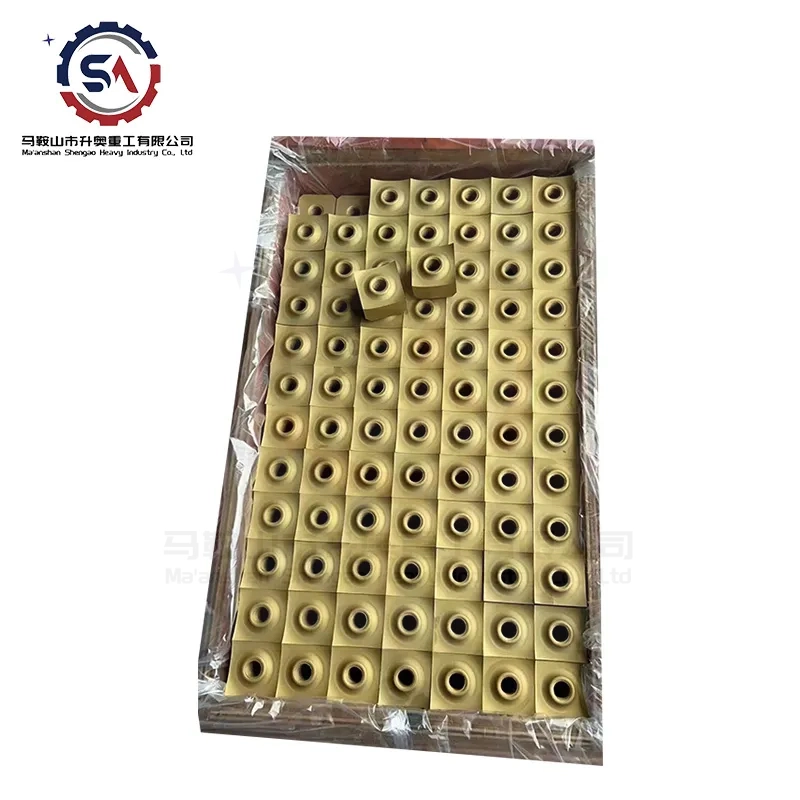

Dual-shaft (or twin-shaft) shredders utilize two intermeshing rotors equipped with cutting discs. The primary action here is shearing and scissoring. The double shaft shredder blades are often hexagonal, square, or star-shaped discs that interlock to slice material into controlled, smaller pieces. This system excels in:

- Homogeneous material streams

- Precise size reduction

- High-volume processing of lighter materials

- Electronic waste (WEEE)

- Paper and cardboard

ShengAo produces durable and precisely calibrated dual-shaft blades that ensure smooth intermeshing, minimal vibration, and a consistent output size, making them perfect for applications where controlled shredding is paramount.

Key Factors for Matching Blades to Your Application

Matching the blade to your application involves a careful analysis of several interdependent factors.

Material Type and Composition

The nature of the material is the most critical determinant.

- Abrasive Materials (Glass-filled plastics, minerals, e-waste): These rapidly wear down standard blades. The solution is a wear-resistant shredder blade made from alloys like D2 shredder blades or those with specialized carbide tips that resist abrasion.

- Tough/Ductile Materials (Purgings, rubber, thick plastics): These require blades with high impact strength and a sharp, aggressive hook to grab and tear. A high hardness shredder blade made from Cr12MoV blade or SKD11 blade is often ideal.

- Stringy/Fibrous Materials (Carpet, textiles, cables): These are prone to wrapping around the rotor. Blades with a sharp, clean-cutting geometry and often a non-stick coating are necessary to prevent this.

- Soft/Brittle Materials (Paper, foam, certain plastics): While less demanding on wear, they require sharp blades to ensure a clean cut and prevent dusting or uneven shredding.

Desired Output Size and Shape

The final product specification dictates the blade's cutting chamber design and the rotor speed. A smaller output size requires more cutting edges and a closer tolerance between the rotor shredder knives and the bed knife. The blade geometry (hook angle, cutting edge sharpness) is fine-tuned to produce the desired chip or flake shape, which is crucial for downstream processes like extrusion or pelletizing.

Throughput and Operational Hours

High-volume, 24/7 operations cannot afford frequent blade changes. For these demanding environments, Long life shredder blades are not a luxury but a necessity. This is achieved through the use of premium steel, advanced heat treatment (like cryogenic processing), and specialized wear-protection coatings. Investing in these high hardness shredder blades upfront significantly reduces the total cost of ownership by maximizing uptime.

Blade Material and Hardness (The Heart of Performance)

The base material of the blade is its foundation. ShengAo utilizes a range of high-performance steels to meet every challenge:

- Cr12MoV (AISI D3): An excellent cold-work tool steel offering great wear resistance and toughness after heat treatment. Perfect for plastic recycling blades and general-purpose shredding.

- SKD-11 (AISI D2): A high-carbon, high-chromium steel known for its exceptional wear resistance. It holds an edge longer than Cr12MoV and is ideal for blades for recycling abrasive materials and e-waste shredder blades.

- D2 Steel: Similar to SKD-11, it's a benchmark for hardened shredder blade applications, offering a superb balance between hardness and toughness.

- HSS (M2): Used in specific applications where high red-hardness (ability to retain hardness at high temperatures) is required.

- Carbide-Tipped Blades: For the most extreme abrasive applications, we offer blades with brazed tungsten carbide tips. These wear-resistant shredder blades can outperform standard steel blades by 10-20 times in certain scenarios.

The hardness, measured on the Rockwell C scale (HRC), is precisely controlled. For most shredding applications, a hardness between HRC 58-62 provides the ideal compromise between a sharp, durable edge and the necessary toughness to resist chipping.

ShengAo Expertise: Engineering Blades for Every Scenario

At ShengAo, we don't just sell blades; we provide engineered solutions. Here’s how we match our ShengAo blades to specific material streams.

Shredder Blades for Plastic Recycling

Plastic shredder machine blades must handle a vast spectrum of materials, from soft LDPE film to glass-filled nylon. For film and soft plastics, sharp, clean-cutting blades prevent melting and wrapping. For hard plastics and purgings, we recommend our robust single shaft shredder blades made from SKD11 blade or Cr12MoV blade for their superior impact and wear resistance. The goal is a consistent flake that is ideal for washing and pelletizing lines.

Metal Scrap Shredder Blades

Shredding metal demands the ultimate in toughness and wear resistance. Our metal scrap shredder blades are forged from premium alloys and heat-treated to withstand the immense forces involved. The blade geometry is designed to shear and tear through thin gauge metals, aluminum, and non-ferrous scrap without catastrophic failure. For this application, the durability of our D2 steel shredder blades is often the preferred choice.

E-Waste Shredder Blades

E-waste is a complex and highly abrasive mix of plastics, metals, and circuit boards. Blades for e-waste recycling must be exceptionally wear-resistant. Our solution often involves SKD-11 shredder blades or even carbide-enhanced designs to combat the silica and glass fibers present. The precise shearing action of our dual-shaft blades is also excellent for liberating and separating materials for recovery.

Blades for Wood Waste Shredding

Whether it's pallets, construction waste, or logging residue, Blades for wood waste shredding need to handle both impact from nails and dirt and the abrasive nature of wood. Our heavy-duty single-shaft blades, with their aggressive hook design, are perfect for this, turning bulky wood into valuable biomass fuel or boiler feedstock.

Shredder Blades for Rubber Tires

Whole tires are one of the most challenging materials to shred due to their toughness and the high presence of steel cord. This application requires immensely strong single shaft shredder blades with a geometry that can grab and rip the rubber while shearing through the steel belts. The high shock load necessitates a blade with excellent core toughness to prevent breakage.

Shredder Blades for Paper and Fiber

For Shredder blades for paper and fiber, the priority is a clean, sharp cut to prevent dust and ensure efficient baling or pulping. Sharp, durable blades made from materials like Cr12MoV provide long life and consistent performance in high-volume paper and cardboard recycling operations.

Universal Compatibility: ShengAo Blades for Major Shredder Brands

A common concern is finding high-quality, cost-effective replacement blades for specific shredder brands. At ShengAo, our core strength lies in our ability to provide Custom shredder blades OEM solutions. We are not just a supplier; we are a manufacturing partner that can reverse-engineer and produce precision blades that are fully compatible with a wide range of international shredder manufacturers. Our blades are engineered to match or exceed the performance of original parts, often at a more competitive shredder blades factory price.

Here are some of the major brands our custom shredder blades are compatible with:

- Metso: We provide durable replacement blades for Metso shredders used in heavy-duty recycling and waste processing.

- Vecoplan: Our precision-engineered single and dual-shaft blades are a perfect match for Vecoplan's high-performance shredding technology.

- UNTHA: We manufacture reliable blades compatible with various UNTHA shredding systems, known for their precision engineering.

- WEIMA: For WEIMA's extensive range of size reduction equipment, we offer robust blades that ensure consistent output and long service life.

- Genox Recycling: Our blades are designed to fit Genox shredders, providing excellent performance in plastic and e-waste recycling applications.

- Harden Machinery: We supply compatible blades for Harden's shredders, focusing on durability for challenging material streams.

- GEP ECOTECH: Our custom solutions work seamlessly with GEP ECOTECH shredders, supporting their smart solid waste disposal systems.

- Maxin India Machinery: We provide effective blade replacements for Maxin's range of recycling and fertilizer shredders.

- Hammel: For Hammel's powerful primary and secondary shredders, we manufacture heavy-duty blades capable of handling the toughest materials.

- Arjes: Our blades are compatible with Arjes shredders, known for their slow-speed, high-torque processing of diverse materials.

- Stiler: We offer precision blades for Stiler shredders, ensuring efficient size reduction in various industrial applications.

- Olnova: Our custom-manufactured blades are designed to fit Olnova machines, providing a reliable and cost-effective replacement option.

By choosing ShengAo as your Shredder blades supplier, you gain the flexibility to buy shredder blades online that are tailor-made for your machine and your specific material, eliminating compatibility issues and performance gaps.

Conclusion: Partner with ShengAo for Unmatched Performance

Matching the right shredder blade to your application is a strategic decision that directly impacts your bottom line. It requires a deep understanding of material science, cutting mechanics, and operational demands. By considering the factors outlined in this guide—shredder type, material composition, desired output, and blade metallurgy—you can make an informed choice that maximizes uptime, reduces operating costs, and ensures a high-quality output.

As a leading Single shaft blades manufacturer and supplier of dual-shaft systems, ShengAo is committed to being your partner in this process. We combine premium materials like Cr12MoV and SKD-11 with precision engineering and a deep commitment to OEM shredder blades customization. Don't let the wrong blade slow you down.

Ready to optimize your shredding operation? Explore our full range of high-performance solutions and discover the ShengAo difference. For our international clients, you can learn more in your preferred language: 日本のお客様は、産業用シュレッダーブレードをご覧ください。 Русскоязычные клиенты могут ознакомиться с информацией на странице: Промышленные ножи для шредеров.

Upgrade to blades engineered for performance and longevity. Contact ShengAo today for a consultation and quote.