5 Tips to Extend Your Circular Blades' Lifespan and Save Money

5 Tips to Extend Your Circular Blades' Lifespan and Save Money

Table of Contents

Premature wear, frequent replacements, and inconsistent cuts are costly headaches in any operation relying on industrial circular blades. The lifespan of your circular blades directly impacts your bottom line through replacement part costs, machine downtime, and product quality. This article provides five actionable, expert-backed strategies to maximize your blade longevity. By focusing on proper cutting techniques, disciplined maintenance, correct cleaning, optimal storage, and smart initial investment, you can significantly reduce operational expenses and enhance productivity. Implementing these tips will help you get the most value from every blade, ensuring cleaner cuts for longer and protecting your machinery from undue stress.

1. Adopt Correct Cutting Techniques for Your Material

Using the wrong cutting approach for your material is a primary cause of accelerated blade wear. The force, speed, and feed rate must be precisely matched to what you're cutting.

Match Blade Specification to Material Hardness

A blade designed for soft plastic will degrade rapidly if used on hardwood or metal composite. Always refer to the blade's material specification and intended application. For challenging materials, consider tungsten carbide circular blades for their superior wear resistance.

Optimize Cutting Speed and Feed Rate

Running blades too fast generates excessive heat, which can soften the cutting edge (tempering). Feeding material too slowly causes friction and grinding instead of clean shearing. Conversely, forcing material too quickly can chip or crack the blade. Consult your machine manual and start with manufacturer-recommended settings.

Ensure Proper Machine Alignment and Support

A misaligned arbor, worn bearings, or insufficient material support forces the blade to cut unevenly, causing one side to wear faster and increasing the risk of breakage. Regular machine calibration is as important as blade care.

2. Implement a Rigorous and Regular Maintenance Schedule

Proactive maintenance prevents minor issues from becoming major failures. A scheduled approach is far more cost-effective than reactive repairs.

Establish Sharpening Intervals Based on Use

Don't wait for a blade to become completely dull. Schedule sharpening based on hours of operation or volume of material processed. A slightly dull blade requires more force to cut, generating heat and stressing the machine. Our video guide on sharpening circular blades demonstrates proper techniques.

Check and Tighten Fasteners Regularly

Vibration can loosen the bolts or nuts holding the blade in place. A loose blade is dangerous and will cut inaccurately, leading to uneven wear. Make torque-checking a part of your routine pre-operation inspection.

Lubricate According to Manufacturer Guidelines

Some cutting applications benefit from appropriate lubrication to reduce heat and friction. Use only the recommended lubricant type and amount, as some materials (like certain plastics or papers) must be cut dry.

3. Master the Art of Proper Cleaning and Inspection

Residue buildup (like adhesive, sap, or plastic melt) on a blade affects its cutting geometry, increases drag, and promotes corrosion. A clean blade is a efficient, long-lasting blade.

Clean Blades After Use or During Scheduled Downtime

Use appropriate cleaners—often a specialized solvent or biodegradable cleaner—to remove residue. Avoid abrasive pads that can scratch the blade surface. Dry the blade thoroughly immediately after cleaning to prevent water spots or rust.

Conduct Detailed Visual and Physical Inspections

Look for the following signs of wear or damage. Catching issues early can allow for repair or timely replacement planning.

| Sign of Wear/Damage | Potential Cause | Action Required |

|---|---|---|

| Small nicks or rolled edges | Hitting foreign objects, improper feed. | Minor sharpening may resolve. |

| Visible rounding of the cutting edge | Normal abrasive wear from use. | Time for professional sharpening. |

| Cracks or chips | Excessive force, material jam, fatigue. | Replace blade immediately. Do not use. |

| Discoloration (blue or brown tints) | Overheating during cutting or sharpening. | Blade may be softened; assess performance. |

| Uniform rust or pitting | Exposure to moisture, improper storage. | Clean and polish; if deep, replace. |

For a deeper understanding of what to look for, our industrial circular blade guide offers comprehensive insights.

4. Optimize Storage Conditions to Prevent Damage

How you store blades when they're not in use is critical to preserving their integrity. Poor storage is a common, yet easily avoidable, source of damage.

Use Individual Protective Holders or Cases

Blades should never be stacked loosely in a drawer or box where their edges can knock against each other or other tools. Invest in blade-specific sleeves, wall racks, or original packaging.

Control the Storage Environment

Store blades in a cool, dry place. Humidity is the enemy of steel, leading to corrosion that pits and weakens the cutting edge. Consider using desiccant packs in storage cabinets in humid climates.

Label and Organize Blades

Clearly label blades with their specification (diameter, material, application) to prevent misuse. An organized system ensures the right blade is used for the job and is easily accounted for during inventory checks.

5. Invest in High-Quality Blades from the Start

While upfront cost is a factor, the true cost of a blade is measured over its entire service life. A cheaper, lower-quality blade often proves more expensive due to frequent replacement, downtime, and inferior results.

Choose the Right Material for Long-Term Performance

High-quality tool steels (like D2, A8) or carbide-tipped blades last significantly longer than generic carbon steel blades for demanding applications. They hold their edge longer and resist wear and heat. Explore the options in our blade materials classification guide.

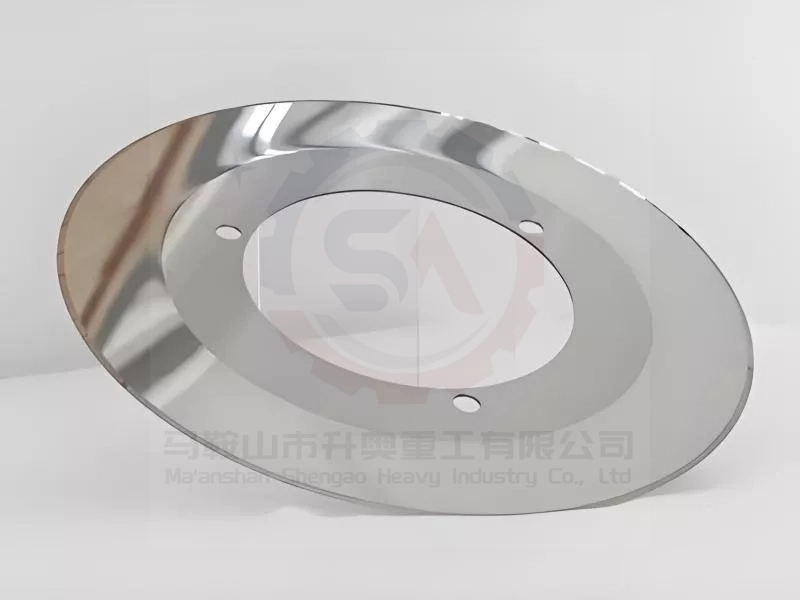

Prioritize Precision Manufacturing

Blades from reputable manufacturers like ShengAo undergo precise heat treatment and grinding. This ensures consistent hardness, perfect balance, and a true cutting geometry, which reduces vibration and wear on your machine spindle.

Consider Specialized Coatings

For specific applications, coatings like titanium nitride (TiN) or chromium nitride (CrN) can dramatically reduce friction, resist adhesion, and enhance corrosion resistance, extending time between sharpening intervals. Learn about professional cutting blade solutions that incorporate these advanced features.

Final Thoughts

Extending the lifespan of your circular blades is a strategic practice that combines operational diligence with smart procurement. It's not merely about saving money on the blades themselves, but about maximizing overall equipment effectiveness, ensuring consistent product quality, and minimizing unplanned downtime. By mastering correct cutting techniques, adhering to a strict maintenance and cleaning regimen, storing blades responsibly, and partnering with a quality-focused manufacturer for your initial purchase, you transform blade management from a cost center into a source of reliability and value. Start applying these five tips today to cut costs, not corners, in your production process.