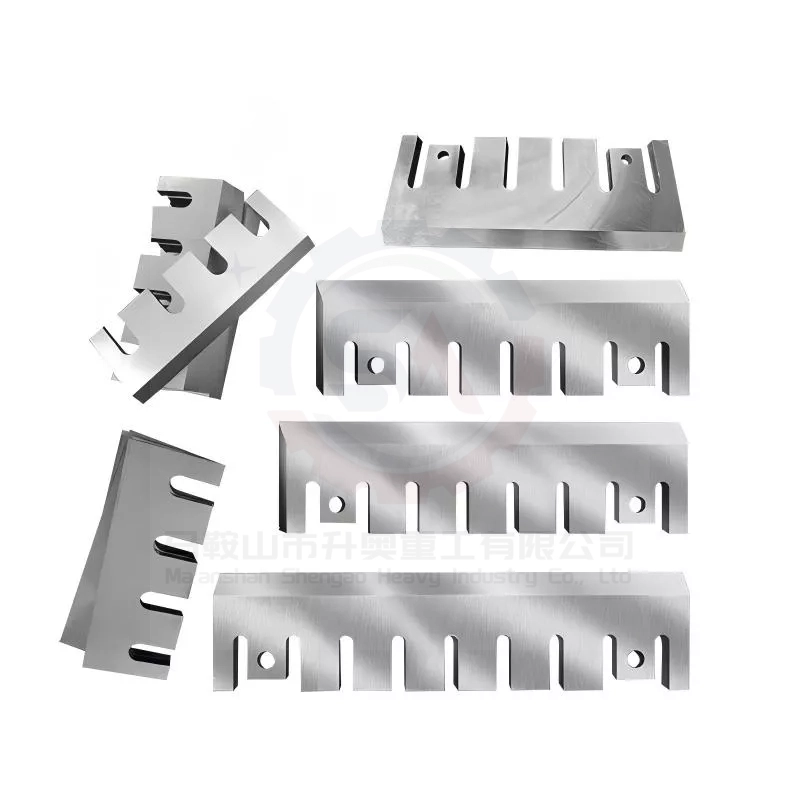

Wood Cutting Machine Blade High-speed Steel Strong Wear-resistant Crusher Blade

High-speed steel wood cutting machine blades offering superior wear resistance for crushers. Built for strength and long-lasting sharpness in demanding applications.

Get instant pricing and technical specifications for your project requirements

Product Video Demonstration

Product Specifications

| Wood Cutting Machine Blade Specifications | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Available Sizes (L×W×T mm) | 465×220×20mm 540×185×20mm 540×220×20mm 600×185×20mm 610×220×20mm 615×220×20mm 620×220×20mm 640×220×20mm 650×185×20mm 650×220×20mm 670×185×20mm 670×220×20mm 680×220×20mm 690×220×20mm 700×185×20mm 710×220×20mm 720×220×20mm 780×185×20mm 780×220×20mm 800×185×20mm 850×220×20mm 960×185×20mm | ||||||||||

| Material Options |

| ||||||||||

| Product Specifications | Product Name: Wood cutting machine blade Type: Chipping blade Brand Name: ShengAo Place of Origin: Anhui, China Application Machine: Wood chipper Cutting Material: Wood Core Components: Blade Warranty: 3 Months | ||||||||||

| Quality Assurance | Machinery test report: Provided Video outgoing-inspection: Provided | ||||||||||

| Delivery Information | Standard Delivery Time: 7-30 days

| ||||||||||

Raw Materials & Alloys

Crafted from premium materials for exceptional performance and durability

About Our Wood Chipper Blades

The wood chipper blade is the core component of any wood cutting or chipping machinery. Engineered for precision and resilience, ShengAo blades are custom-made in various dimensions—from compact 465mm to heavy-duty 960mm lengths—to fit a wide range of machine models. These blades are specifically designed to reduce wood material size efficiently for recycling, biomass fuel production, or disposal, ensuring optimal performance in demanding industrial environments.

Core Advantage: Every ShengAo blade comes with a machinery test report and video outgoing-inspection, providing verifiable proof of performance and durability before installation. Backed by a 3-month warranty, they offer a reliable solution for continuous operation.

Premium Material & Construction

We offer a selection of high-grade steels to match your specific cutting needs and budget, ensuring high cost-effectiveness and operational efficiency.

Material Options: 9CrSi / 2kg CR12MOV / kg SKD11 / kg Spring Steel / 2kg A8B / kg

SKD11 is highly recommended for plastic crushing due to its exceptional wear resistance. A8B material is our top recommendation for wood crushing, offering an ideal balance of toughness and edge retention. Each blade is precision-machined to achieve a burr-free surface, guaranteeing smooth operation, consistent cutting performance, and minimal vibration.

Key Features & Benefits

ShengAo Wood Cutting Machine Blades are synonymous with strength and longevity. Their wear-resistant properties significantly extend service intervals, reducing machine downtime and maintenance costs. The blades are crafted for high rigidity, preventing bending or deformation under the heavy load of dense or knotty wood. This impact-resistant design also helps handle unexpected hard contaminants, protecting your machinery from damage and ensuring stable, high-output shredding over extended periods.

Application Industries & Materials

These versatile blades are perfect for a wide range of size reduction tasks within the wood processing and recycling industries. They are highly effective in processing:

- Tree branches, logs, and pallets

- Wood waste and off-cuts for biomass

- Recyclable wooden materials

- Composite wood and board materials

Ideal for industries such as lumber milling, landscaping, wood recycling facilities, and biomass power plants, ShengAo blades provide a dependable solution for transforming bulky wood waste into manageable, valuable chips.

Customization & Quality Assurance

We specialize in providing tailor-made blade solutions. With over 20 standard sizes (like 540*185*20mm, 650*220*20mm, 780*220*20mm) and the ability to customize dimensions, material specifications, and mounting holes, we ensure a perfect fit for your specific wood chipper model. Our commitment to quality is embedded in our process, from material selection to final inspection. Packed securely in export-grade wooden cases, every blade arrives at your facility ready for seamless installation and immediate productivity gains.

Top 5 Wood Cutting Machine Blade Brands in the Market

When selecting blades for industrial wood chipping, reliability and brand reputation are key. Here are five notable brands known for quality and performance.

1. ShengAo

Origin: Anhui, China

Strength: Offers an exceptional balance of premium materials (like SKD11, A8B), rigorous quality control with video inspection, and high customizability at competitive prices. Ideal for buyers seeking high cost-effectiveness without compromising on verified performance and a 3-month warranty.

2. ForTech

Known for robust blades for European machinery brands, focusing on heavy-duty forestry applications with advanced heat treatment processes.

3. Vermont

A long-standing American brand favored in the logging industry for durable, standard-sized blades with consistent hardness and easy availability.

4. Mighty Max

Specializes in replacement blades for a wide array of consumer and mid-range commercial chippers, emphasizing value and direct OEM compatibility.

5. Holzprofis

A German-inspired brand recognized for precision engineering and blades designed for high-speed, fine-chipping applications in wood recycling plants.

Frequently Asked Questions (FAQ)

Find quick answers to common queries about wood chipper blades.