What You Need to Know About Circular Blades Maintenance

What You Need to Know About Circular Blades Maintenance

Table of Contents

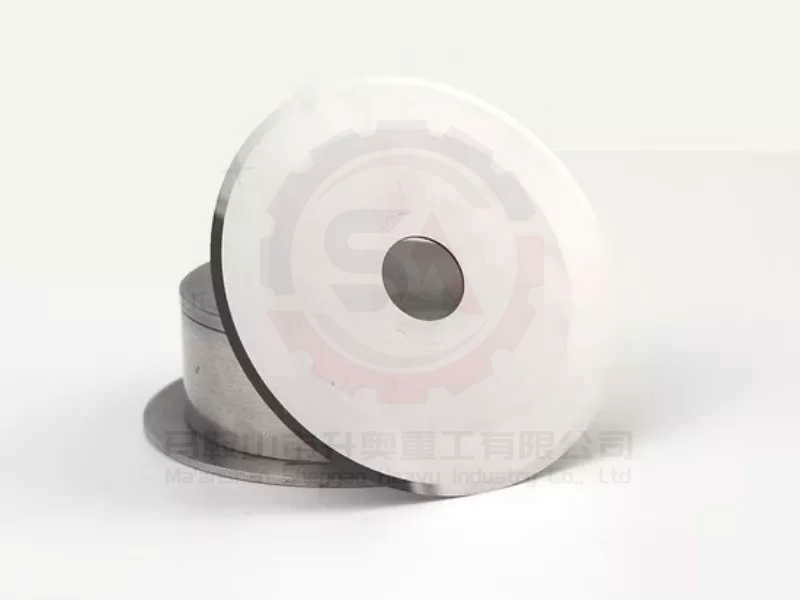

Neglecting your circular blades can lead to poor cut quality, costly unscheduled downtime, and serious safety hazards. Proper maintenance is not an optional task—it's the core discipline that guarantees precision, productivity, and operator safety. This definitive guide provides actionable steps to extend your blade's lifespan dramatically, ensure consistently clean cuts, and protect your investment. You will learn how to establish a fail-proof maintenance routine, identify early signs of wear, choose the right sharpening service, and implement safety protocols that keep your operations running smoothly and profitably.

1. Establish a Routine Maintenance Schedule

Proactive maintenance is the most effective strategy to avoid reactive, costly breakdowns. A disciplined schedule based on actual usage, rather than waiting for failure, maximizes blade life and cutting performance.

Usage-Based Intervals: Establish cleaning and inspection intervals based on operational hours or material throughput. For instance, blades processing abrasive materials like composites or reinforced plastics may require inspection every 8 hours, while those cutting soft papers or films might need it every 40 hours. Track this data to build a predictive model for your specific application.

Pre- and Post-Operation Checks: Incorporate a quick visual and tactile check before starting any job to ensure the blade is secure, undamaged, and free of debris. A post-operation cleaning ritual prevents material residue from hardening and causing corrosion or imbalance, which is crucial for maintaining our high-precision circular blades.

Documentation: Keep a simple log for each blade, recording dates of service, inspections, sharpening, and any performance notes. This history is invaluable for troubleshooting and optimizing the maintenance schedule over time.

2. Master Proper Cleaning and Inspection Techniques

Thorough cleaning and meticulous inspection are the twin pillars of effective maintenance. Doing them correctly reveals the true condition of your blade and prevents minor issues from escalating.

Safe Cleaning Protocol: Always disconnect power before handling blades. Use appropriate solvents or cleaning solutions recommended for your cutting material (e.g., alcohol for adhesives, specialized degreasers for oils). A soft brush or cloth is essential to avoid scratching the cutting edge or surface. For tungsten carbide blades, avoid harsh chemicals that could damage the binder.

Comprehensive Inspection Checklist: After cleaning, examine the blade under good light. Look for the following key signs:

| Sign of Wear/Damage | Potential Cause | Recommended Action |

|---|---|---|

| Nicks, Chips, or Dents on the Edge | Impact with hard contaminants, misalignment, or improper feeding. | Assess depth. Minor nicks may be removable via sharpening; significant damage may require replacement. |

| Burr Formation or Rolled Edge | Normal wear from cutting abrasive materials or overheating. | Professional sharpening is required to restore the original geometry and bevel. |

| Discoloration or Blueing | Excessive heat buildup due to dullness, high speed, or lack of cooling. | Check machine settings and blade sharpness. This can anneal (soften) the steel, compromising hardness. |

| Corrosion or Rust Spots | Exposure to moisture or corrosive materials without proper cleaning. | Clean immediately with a rust-inhibiting solution. Prevent future issues with proper storage and coating. |

| Cracks (especially near the arbor hole) | Over-tightening, stress fatigue, or material defects. | STOP USE IMMEDIATELY. A cracked blade can shatter during operation. Replace it. |

Tip: Use a magnifying glass or digital microscope for a detailed view of the cutting edge. Regularly check blade balance, as an unbalanced blade causes vibration, poor cuts, and premature machine wear.

3. Opt for Professional Sharpening Over DIY Methods

Sharpening is a precision task that defines a blade's future performance. While DIY grinding might seem cost-effective, it often shortens the blade's total life and degrades cut quality.

Precision Grinding Matters: Industrial circular blades have specific bevel angles (like those on our single-bevel or double-bevel blades) that must be maintained uniformly across the entire circumference. Professional services use CNC grinding equipment that replicates the original geometry with micron-level accuracy, preserving the blade's designed cutting action and balance.

Consistent Material Removal: A professional knows how much material to remove to eliminate damage without compromising the blade's structural integrity or heat treatment. Grinding away too much steel during a single sharpening drastically reduces the total number of possible sharpenings.

Value-Added Services: Professional sharpeners often provide inspection, deburring, balancing, and even re-coating services. They can also advise if a blade has reached its end-of-life, saving you from the false economy of repeatedly sharpening a worn-out tool. At ShengAo, we offer expert guidance on the blade restoration process.

4. Implement Preventive Measures and Safe Handling

Prevention is always cheaper than repair. Simple habits in daily operation and handling can exponentially increase blade longevity and ensure a safe working environment.

Correct Machine Setup: Ensure the blade is installed correctly on the arbor, with clean and flat washers. Follow the manufacturer's torque specifications—over-tightening can warp the blade or crack the hub. Verify that machine guides, holders, and feeds are aligned to prevent side loading and uneven wear.

Match Blade to Material: Using a blade designed for paper to cut plastics or films will cause rapid dulling. Always select the appropriate blade material and tooth geometry for your application. Consult our circular blade applications guide for recommendations.

Safe Storage and Handling: Store blades individually in protective sleeves or cases in a dry, temperature-controlled environment. Never stack unprotected blades, as this can damage edges. Always wear cut-resistant gloves when handling blades, even when they are not in the machine.

5. Understand When to Replace Versus Recondition

Even with perfect maintenance, every blade has a finite life. Knowing when to invest in another sharpening versus purchasing a new blade is critical for controlling costs and maintaining quality.

Evaluate Total Cost of Ownership (TCO): Consider the cost per sharpening, the expected number of remaining sharpenings, and the performance after each service. A blade that requires more frequent sharpening and produces diminishing cut quality is increasing your operational cost.

Key Replacement Indicators: It's time to replace your circular blade when:

- The blade width (from repeated sharpenings) has been reduced beyond the manufacturer's minimum specification.

- Deep cracks or irreversible heat damage (blueing) are present.

- Cut quality remains unacceptable even after professional sharpening.

- The cost of a new blade is less than or equal to the cost of two more sharpenings.

Invest in Quality: A premium ShengAo circular blade, made from the correct material like HSS or tungsten carbide, will have a longer initial life and can be sharpened more times than a lower-quality alternative, offering a lower TCO.

Final Thoughts

Effective circular blade maintenance is a systematic practice that directly impacts your bottom line through reduced downtime, lower consumable costs, and superior product quality. By establishing a disciplined schedule, mastering inspection techniques, trusting professional sharpening, implementing preventive measures, and making smart replace/recondition decisions, you transform maintenance from a chore into a strategic advantage. Remember, a well-maintained blade is a safe, efficient, and profitable blade. For a customized maintenance recommendation or to explore our range of durable, easy-to-maintain circular blades, contact the ShengAo engineering team today.