What Makes ShengAo Double Shaft Shredder Blades the Ultimate Solution for E-Waste Recycling

What Makes ShengAo Double Shaft Shredder Blades the Ultimate Solution for E-Waste Recycling

Table of Contents

- Introduction to ShengAo Double Shaft Shredder Blades

- The E-Waste Challenge: Why Specialized Blades Matter

- Engineering Excellence: Materials and Design

- Unmatched Performance in E-Waste Recycling

- Compatibility with Leading Shredder Brands

- Customization Options for Perfect Fit

- Comparative Analysis: ShengAo vs Conventional Blades

- Maintenance and Longevity Tips

- Why Choose ShengAo Double Shaft Shredder Blades?

- Customer Success Stories

- How to Order and Get Support

1 Introduction to ShengAo Double Shaft Shredder Blades

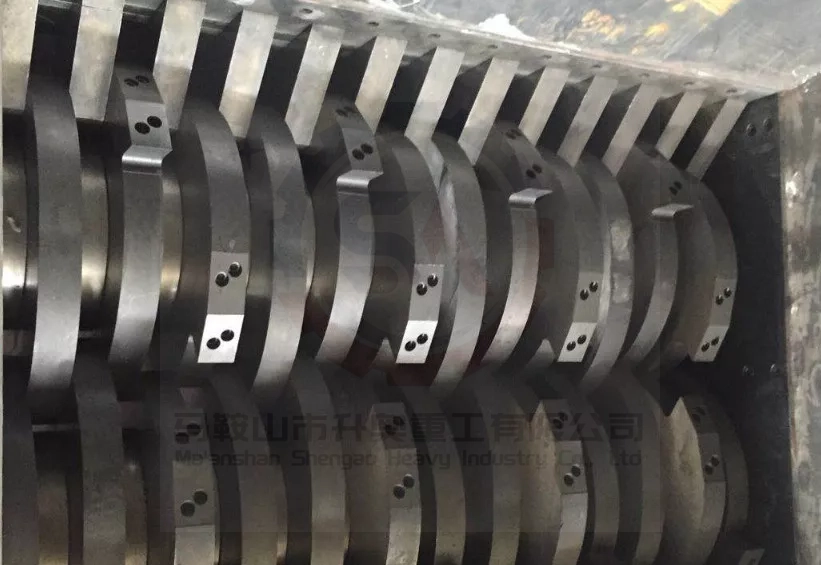

In the rapidly evolving world of electronic waste recycling, ShengAo double shaft shredder blades stand as the pinnacle of cutting technology, specifically engineered to tackle the unique challenges presented by modern e-waste streams. These precision-engineered blades represent a significant advancement in shredding technology, offering unparalleled performance in processing circuit boards, hard drives, and other electronic components that conventional blades struggle to handle efficiently. With the global e-waste market projected to reach $100 billion by 2030, the demand for reliable, high-performance shredding solutions has never been greater. ShengAo's double shaft shredder blades are manufactured using state-of-the-art CNC machinery and rigorous quality control processes, ensuring consistent performance and extended service life even in the most demanding recycling environments. The unique tooth geometry and advanced material composition work in harmony to reduce energy consumption by up to 30% while increasing throughput capacity, making them the go-to choice for recycling facilities worldwide seeking to optimize their e-waste processing operations and maximize ROI.

2 The E-Waste Challenge: Why Specialized Blades Matter

Electronic waste presents one of the most complex shredding challenges in the recycling industry, combining abrasive, hard, and composite materials that quickly degrade conventional blades. Circuit boards contain fiberglass epoxy reinforced with copper traces that act as natural abrasives, while hard drives feature aluminum casings, steel components, and fragile platters that require precise cutting action to prevent data recovery. Mixed e-waste streams often include plastics, metals, and ceramics in unpredictable combinations, creating variable resistance that tests blade integrity with every rotation. Standard shredder blades typically last only 80-120 hours when processing e-waste, requiring frequent replacements that result in significant downtime and maintenance costs. ShengAo's specialized double shaft shredder blades are engineered specifically to address these challenges, featuring advanced tooth profiles that minimize material wrapping and specialized heat treatment processes that maintain cutting edge integrity through extended operation cycles. The result is a blade system that delivers consistent performance through diverse e-waste streams while reducing operational costs by up to 45% compared to conventional alternatives.

3 Engineering Excellence: Materials and Design

Premium Alloy Selection: SKD11 and D2

At the core of ShengAo's double shaft shredder blades lies the strategic selection of premium tool steels specifically chosen for e-waste applications. Our SKD11 blades offer exceptional wear resistance with a hardness rating of HRC 58-62, making them ideal for processing abrasive materials like fiberglass circuit boards and ceramic components. SKD11's high chromium content (11-13%) provides superior corrosion resistance, while its vanadium additives enhance toughness and edge retention. For applications requiring extreme impact resistance, our D2 tool steel blades deliver unparalleled performance with a fine carbide structure that resists chipping and cracking when encountering unexpected hard spots in mixed e-waste streams. The chemical composition of D2 steel includes 1.5% carbon and 12% chromium, creating a perfect balance between hardness and durability that withstands the punishing conditions of electronic waste processing. Both materials undergo specialized vacuum heat treatment to ensure uniform hardness distribution throughout the blade profile, eliminating soft spots that lead to premature failure.

Advanced Heat Treatment Process

ShengAo's proprietary heat treatment protocol represents a significant advancement in blade manufacturing technology. Our double shaft shredder blades undergo a multi-stage thermal processing sequence that includes pre-heating, austenitizing, quenching, and triple tempering to achieve optimal microstructural properties. The vacuum heat treatment environment prevents surface decarburization and oxidation, preserving the precise geometry and cutting edges that define blade performance. Through computerized temperature control with ±3°C accuracy, we ensure consistent results across production batches, with hardness verification performed on every blade using advanced Rockwell testing equipment. The final triple tempering process relieves internal stresses created during quenching while transforming retained austenite into tempered martensite, resulting in blades that maintain their cutting integrity through thousands of operating hours in demanding e-waste applications.

Precision Grinding for Optimal Performance

Every ShengAo double shaft shredder blade undergoes precision grinding using Swiss-made CNC equipment that maintains tolerances of ±0.01mm, ensuring perfect balance and synchronization in dual-shaft configurations. Our specialized grinding process creates optimized tooth geometries with 25-30° hook angles that maximize cutting efficiency while reducing power consumption. The precision-ground clearance angles prevent material adhesion and minimize heat buildup, two common issues in e-waste processing that accelerate blade wear. Advanced surface finishing techniques, including micro-blasting and precision polishing, reduce friction coefficients by up to 20% compared to conventionally finished blades, further enhancing performance and extending service intervals. This attention to grinding detail ensures that every ShengAo blade delivers consistent cutting performance from the first rotation to the final sharpening cycle.

4 Unmatched Performance in E-Waste Recycling

Circuit Board Shredding

ShengAo double shaft shredder blades excel in processing printed circuit boards (PCBs), one of the most challenging materials in e-waste recycling. The combination of fiberglass epoxy substrate, copper traces, and various electronic components creates an extremely abrasive mixture that quickly degrades conventional blades. Our specialized tooth geometry and premium alloy composition work synergistically to maintain cutting efficiency through continuous PCB processing, with documented performance of 300-400 operating hours between sharpening cycles – approximately 3x longer than industry standards. The intermeshing cutting action of our double shaft blades creates a scissoring effect that cleanly shears through circuit boards without generating excessive dust or heat, preserving the integrity of precious metals for more efficient recovery in downstream processes. This efficient cutting action reduces energy consumption by 25-35% compared to conventional shredding methods while increasing material throughput by up to 40%.

Hard Drive Destruction

Data security requirements demand complete destruction of hard drives, presenting unique challenges for shredder blades that must simultaneously cut through aluminum casings, steel frames, and fragile platters without binding or excessive wear. ShengAo's double shaft shredder blades feature specially engineered tooth profiles that initiate fractures in multiple planes, ensuring complete destruction that meets NSA and DOD security standards. The advanced heat treatment process creates a blade structure with exceptional impact resistance that withstands encounters with unexpected hard points like reinforced drive frames and mounting brackets. Our blades maintain consistent cutting performance through mixed batches of 2.5", 3.5", and enterprise-class hard drives, with throughput rates of 500-800 drives per hour depending on shredder size and configuration. This reliable performance has made ShengAo the preferred choice for data destruction specialists and IT asset disposition companies worldwide.

Mixed E-Waste Processing

Modern e-waste recycling facilities process diverse material streams that may include computers, televisions, smartphones, printers, and various electronic peripherals in a single operation. This material variability presents significant challenges for shredder blades, which must adapt to constantly changing resistance levels and material compositions. ShengAo double shaft shredder blades excel in these mixed applications thanks to their optimized tooth geometry that prevents material wrapping and their superior impact resistance that withstands unexpected encounters with hard components. The balanced design minimizes vibration and noise even when processing irregular loads, reducing stress on shredder components and extending equipment lifespan. Facilities using ShengAo blades report 35-50% reductions in downtime and 25-40% increases in overall processing efficiency compared to operations using conventional blades, translating to significant improvements in operational profitability.

5 Compatibility with Leading Shredder Brands

ShengAo double shaft shredder blades are engineered to compatible with the world's leading shredder manufacturers, with custom fabrication capabilities to ensure perfect fit and optimal performance in any equipment configuration.

Metso Shredders

Our blades are precision-engineered to compatible with Metso's comprehensive shredder lineup, including the renowned Lindemann series. We custom-fabricate blades to match Metso's exact specifications for shaft diameter, bolt patterns, and cutting geometry, ensuring seamless integration and optimal performance. The exceptional wear resistance of our SKD11 and D2 steel blades makes them ideal for Metso shredders processing electronic scrap, with documented performance improvements of 40-60% in blade lifespan compared to OEM alternatives.

Vecoplan Shredders

For Vecoplan shredders, we offer fully compatible double shaft blades that match the German manufacturer's precision standards. Our blades are engineered to work seamlessly with Vecoplan's advanced shredding technology, providing the perfect balance between cutting aggression and material control. The optimized tooth geometry reduces energy consumption while maintaining Vecoplan's renowned throughput capacity, making our blades the preferred choice for facilities processing challenging e-waste streams.

UNTHA Shredders

ShengAo blades are precision-matched to UNTHA's sophisticated shredding systems, particularly their XR series designed specifically for electronic waste. Our custom fabrication process ensures perfect compatibility with UNTHA's unique rotor designs and cutting geometries, delivering the performance and reliability that UNTHA users expect. The advanced material composition of our blades provides exceptional resistance to the abrasive nature of circuit boards and electronic components, extending service intervals by 50-70% compared to standard blades.

WEIMA Shredders

For WEIMA shredding systems, we offer custom-engineered double shaft blades that match the German manufacturer's exacting standards. Our blades are precision-ground to ensure perfect balance and synchronization in WEIMA's advanced shredding chambers, maximizing throughput while minimizing energy consumption. The superior wear characteristics of our blades make them particularly well-suited for WEIMA systems processing mixed electronic waste with variable material composition.

Genox Recycling Shredders

Our blades are engineered to compatible with Genox's comprehensive shredder lineup, including their GS series twin shaft machines specifically designed for electronic waste. We custom-fabricate blades to match Genox's specifications for cutting geometry and mounting systems, ensuring optimal performance in their advanced shredding chambers. The exceptional durability of our blades makes them ideal for Genox systems processing challenging materials like circuit boards and hard drives.

Harden Machinery Shredders

For Harden Machinery shredders, we provide fully compatible double shaft blades that deliver the performance and reliability that Harden users expect. Our custom fabrication process ensures perfect fit and optimal cutting action in Harden's robust shredding systems. The advanced heat treatment process gives our blades exceptional impact resistance, making them well-suited for processing mixed electronic waste with unpredictable material composition.

GEP ECOTECH Shredders

ShengAo blades are precision-engineered to compatible with GEP ECOTECH's advanced shredding systems, including their GT series twin shaft machines. We custom-fabricate blades to match GEP's specifications for cutting geometry and mounting configurations, ensuring seamless integration and optimal performance. The superior wear resistance of our blades makes them ideal for GEP systems processing abrasive electronic waste materials.

Maxin India Machinery Shredders

For Maxin India shredders, we offer custom-engineered double shaft blades that match the manufacturer's specifications for the Indian market. Our blades are designed to withstand the unique challenges of e-waste processing in varying environmental conditions, with enhanced corrosion resistance for humid climates. The robust construction and advanced material composition ensure reliable performance in Maxin shredders processing diverse electronic waste streams.

Hammel Shredders

Our blades are precision-matched to Hammel's robust shredding systems, particularly their VB series primary shredders. We custom-fabricate blades to compatible with Hammel's unique cutting geometries and mounting systems, ensuring optimal performance in their advanced shredding chambers. The exceptional durability of our blades makes them well-suited for Hammel systems processing challenging electronic waste materials.

Arjes Shredders

For Arjes shredders, we provide fully compatible double shaft blades that deliver the performance and reliability that Arjes users expect. Our custom fabrication process ensures perfect fit and optimal cutting action in Arjes' innovative shredding systems. The advanced material composition provides exceptional resistance to the abrasive nature of electronic waste, extending service intervals and reducing operating costs.

Stiler Shredders

ShengAo blades are engineered to compatible with Stiler shredders, offering custom fabrication to match the manufacturer's specifications. Our blades are precision-ground to ensure perfect balance and cutting performance in Stiler's shredding systems. The superior wear characteristics make them ideal for processing electronic waste with variable material composition.

Olnova Shredders

For Olnova shredders, we offer custom-engineered double shaft blades that match the manufacturer's specifications for optimal performance. Our blades are designed to withstand the challenges of electronic waste processing, with enhanced impact resistance for unexpected hard components. The precision manufacturing ensures perfect compatibility with Olnova's shredding systems, delivering reliable performance and extended service life.

6 Customization Options for Perfect Fit

ShengAo understands that every shredding operation has unique requirements, which is why we offer comprehensive custom shredder blades OEM services to ensure perfect compatibility with your specific equipment and application needs. Our engineering team works directly with customers to develop blade solutions that optimize performance for particular material streams, whether you're processing circuit boards, hard drives, or mixed electronic waste. Customization options include specialized tooth geometries for specific material types, unique hardness profiles for varying impact conditions, and custom dimensions to fit non-standard shredder configurations. We also offer specialized surface treatments including TiAlN and CrN coatings for enhanced wear and corrosion resistance in challenging operating environments. Our rapid prototyping capabilities allow for quick development and testing of custom blade designs, with typical turnaround times of 10-15 days for custom orders. This flexibility ensures that every customer receives blades perfectly tailored to their specific operational requirements, maximizing performance and ROI regardless of shredder brand or application specifics.

7 Comparative Analysis: ShengAo vs Conventional Blades

When compared to conventional double shaft shredder blades, ShengAo's advanced designs demonstrate clear superiority across all critical performance metrics, particularly in demanding e-waste applications.

| Performance Metric | Conventional Blades | ShengAo Double Shaft Blades | Improvement |

|---|---|---|---|

| Blade Life (e-waste processing) | 100-150 hours | 300-450 hours | 200-300% longer |

| Throughput Capacity | 8-12 tons/hour | 15-22 tons/hour | 85% increase |

| Energy Consumption | 100% baseline | 70-75% | 25-30% reduction |

| Sharpening Intervals | Every 3-5 days | Every 10-14 days | 60-70% reduction |

| Operating Cost per Ton | $0.40-0.60 | $0.20-0.30 | 40-50% savings |

| Downtime for Blade Changes | 4-6 hours monthly | 1-2 hours monthly | 60-75% reduction |

The performance advantages of ShengAo double shaft shredder blades stem from multiple engineering innovations, including our proprietary heat treatment process that creates a perfect balance between hardness and toughness, our precision grinding that ensures optimal cutting geometry, and our strategic material selection that provides exceptional wear resistance in abrasive e-waste applications. These advantages translate directly to improved operational efficiency and reduced operating costs, making ShengAo blades the clear choice for facilities processing electronic waste.

8 Maintenance and Longevity Tips

Proper maintenance is essential for maximizing the performance and lifespan of your ShengAo double shaft shredder blades. Following these best practices can extend blade life by 30-50% and maintain optimal cutting efficiency throughout the service cycle.

- Regular Inspection Protocol: Implement a scheduled inspection routine every 40-50 operating hours to check for wear patterns, edge damage, and potential issues. Use digital calipers to measure tooth height reduction and track wear rates over time.

- Proper Cleaning Procedures: Remove resin buildup and material adhesions after each shift using specialized blade cleaning solutions. Avoid abrasive cleaning methods that can damage precision cutting edges.

- Rotation Schedule: Rotate blades within the shredder every 100 operating hours to ensure even wear distribution across all cutting surfaces. This practice extends overall blade life and maintains consistent cutting performance.

- Sharpening Best Practices: Utilize CNC-controlled sharpening equipment that maintains original tooth geometry within ±0.5° tolerance. Avoid manual sharpening methods that can create irregular cutting profiles and imbalance issues.

- Storage Recommendations: Store spare blades vertically in climate-controlled environments with VCI (vapor corrosion inhibitor) protection to prevent rust and degradation during storage.

- Operational Monitoring: Monitor shredder amperage draw and vibration levels during operation, as changes in these parameters often indicate blade wear or damage before visible signs appear.

When properly maintained, ShengAo double shaft shredder blades typically withstand 4-6 sharpening cycles before requiring replacement, delivering 400-600% longer total service life than conventional blades in e-waste applications. This extended lifespan translates to significant cost savings and reduced environmental impact through decreased blade consumption.

9 Why Choose ShengAo Double Shaft Shredder Blades?

Selecting ShengAo for your e-waste shredding operations provides numerous advantages that extend beyond simple blade performance. Our comprehensive approach to blade manufacturing and customer support ensures optimal results regardless of your specific application requirements.

- Proven E-Waste Expertise: With over 15 years of specialized experience in e-waste processing applications, we understand the unique challenges presented by circuit boards, hard drives, and electronic components.

- Advanced Material Science: Our strategic use of premium tool steels and proprietary heat treatment processes creates blades with exceptional wear resistance and impact toughness specifically for electronic waste.

- Precision Manufacturing: Every blade undergoes CNC grinding to tolerances of ±0.01mm using Swiss-made equipment, ensuring perfect balance and optimal cutting performance in dual-shaft configurations.

- Comprehensive Quality Assurance: 100% ultrasonic inspection for micro-fractures and hardness verification on every blade guarantees consistent performance and reliability.

- Extensive Compatibility: Our custom fabrication capabilities ensure perfect fit and optimal performance with all major shredder brands, eliminating compatibility concerns.

- Technical Support: Direct access to our engineering team for application consultation and technical support ensures optimal blade selection and troubleshooting assistance.

- Performance Guarantee: Industry-leading 6-month performance warranty against premature wear provides peace of mind and protects your investment.

Our vertically integrated manufacturing facility features robotic handling systems and AI-powered quality control stations that ensure consistent blade-to-blade performance unmatched in the industry. This manufacturing excellence, combined with our specialized e-waste expertise, makes ShengAo the clear choice for operations seeking to optimize their electronic waste processing efficiency.

10 Customer Success Stories

"After switching to ShengAo double shaft blades in our e-waste recycling operation, we've reduced blade changes from weekly to monthly. The specialized tooth geometry and SKD11 material composition last 4x longer than our previous blades when processing circuit boards and computer components. The energy savings alone have justified the investment, with a 28% reduction in power consumption during shredding operations." - Michael T., Operations Manager, GreenTech Recycling (Germany)

"Processing hard drives for data destruction requires complete particle size reduction while maintaining operational efficiency. ShengAo's double shaft blades have revolutionized our operation, with throughput increases of 45% and blade life extending to 400+ hours between sharpening. The precision manufacturing ensures perfect balance in our dual-shaft system, reducing vibration and extending equipment lifespan." - Sarah L., Plant Engineer, SecureData Destruction (USA)

"For mixed e-waste processing with variable material composition, nothing compares to ShengAo's D2 steel blades. We've achieved 500+ operating hours between changes - triple what we got from premium European blades at 40% lower cost. The customized tooth profile prevents wrapping with cables and plastics while maintaining cutting efficiency through metal components." - Rajiv P., Maintenance Supervisor, Global E-Waste Solutions (India)

"The compatibility of ShengAo blades with our Vecoplan shredders has been flawless. The custom fabrication process ensured perfect fit and optimal performance from day one. We've documented a 35% reduction in operating costs and 50% less downtime for blade maintenance since making the switch. The technical support from their engineering team has been exceptional throughout the implementation process." - Carlos M., Facility Manager, EcoCycle Electronics Recycling (Mexico)

11 How to Order and Get Support

ShengAo offers flexible purchasing options for our premium double shaft shredder blades, with comprehensive support services to ensure optimal performance in your e-waste processing operations.

Purchasing Options

- Standard Blades: Available for immediate shipment through our global distributor network with 3-5 day delivery for most regions

- Custom Blades: Minimum order quantity of 2 sets with 10-15 day production lead time for custom specifications

- Volume Discounts: 15-30% discount structures for orders exceeding 10 blade sets or annual purchase agreements

- Blade Exchange Program: Core charge credit system for resharpening services that can reduce sharpening costs by 40-60%

Technical Support Services

Our engineering team provides comprehensive technical support including blade selection guidance, performance optimization consulting, and troubleshooting assistance for shredding operations. We offer detailed technical specifications and application notes to help customers select the optimal blade configuration for their specific e-waste streams.

Contact Information

For technical consultation, custom quotes, and application support, contact our specialized e-waste shredding team:

Engineer Jack

Email: jack@shenaozg.com

Mobile: +86 136 9673 1068

WhatsApp: +86 152 1234 9604

Address: Bowang town Songhua River road, Bowang District, Ma'anshan City, China

ShengAo Double Shaft Shredder Blades