What Makes Circular Blades the Go-To Tool for Packaging and Textile Industries?

What Makes Circular Blades the Go-To Tool for Packaging and Textile Industries?

Table of Contents

1. The Cutting Edge: Why Circular Blades Are Uniquely Effective

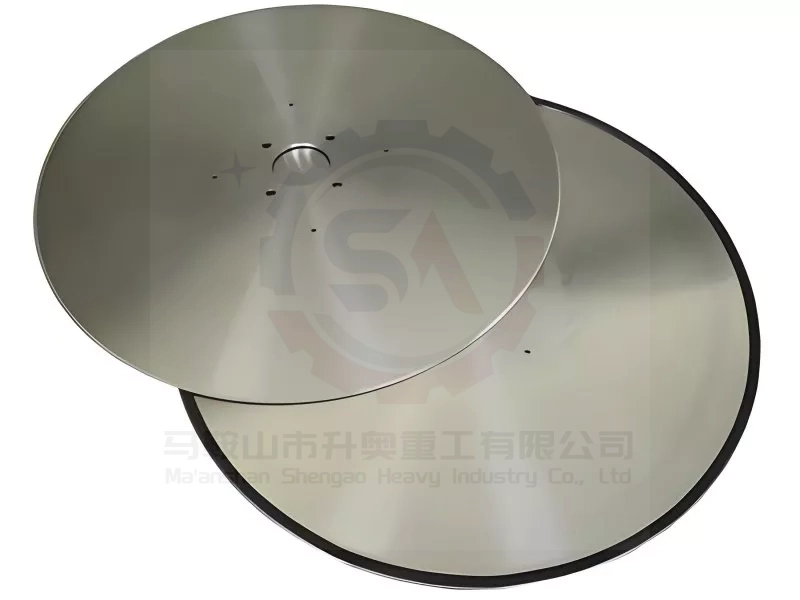

The fundamental geometry of a circular blade is its first advantage. Unlike straight blades, the continuous rotational motion of a circular blade delivers a consistent, shearing cut that minimizes material drag and distortion. This is critical when processing delicate textiles or precision-engineered packaging films where a ragged edge is unacceptable. The circular design allows for extremely high operating speeds, enabling faster production cycles and greater throughput—a key driver of profitability in high-volume industries.

Furthermore, the ability to finely tune the blade's bevel angle, hardness (typically HRC 58-62 for demanding tasks), and edge configuration (plain, serrated, or micro-serrated) allows for unparalleled application-specific optimization. For instance, a micro-serrated edge can perfectly grip and cleanly cut slippery laminated fabrics without slippage, while a polished, plain-edge blade is ideal for achieving glass-smooth cuts in paperboard. This versatility makes the circular blade a universal solution across textile manufacturing and packaging industries.

2. Select the Perfect Material for Your Application

Choosing the correct blade material is the most critical decision to ensure longevity and cut quality. A mismatch leads to rapid dulling, frequent changes, and compromised product finish. The material must be engineered to resist the specific wear mechanisms of your feedstock, whether it's the abrasive nature of fiberglass-reinforced materials, the adhesive quality of melt-blown nonwovens, or the corrosive elements in certain coated papers.

Use this guide to match ShengAo blade materials to common industry challenges:

| Application & Material Challenge | Recommended ShengAo Blade Material | Key Advantage |

|---|---|---|

| Nonwoven Fabrics, Soft Textiles, Paper | High-Grade Tool Steel (D2, SKD-11) | Superior toughness and fatigue resistance for continuous, clean shearing without edge chipping under high-speed operation. |

| Corrugated Cardboard, Rigid Plastics, Composite Films | Through-Hardened Tool Steel (HRC 58-62) | High hardness maintains a keen edge against semi-abrasive materials, ensuring consistent cut quality and preventing premature wear. |

| Abrasive Materials: Fiberglass, Carbon Fiber, Filled Plastics | Solid Tungsten Carbide or Carbide-Tipped | Extreme wear resistance offers 8-10x the service life of tool steel in highly abrasive applications, providing the lowest cost-per-cut. |

| Adhesive Films, Coated Materials, Hygienic Applications | Stainless Steel or Specialty-Coated Blades | Resists material adhesion (anti-stick), prevents corrosion, and meets hygiene standards for sensitive production environments. |

Expert Insight: For textiles prone to fraying, a serrated or toothed circular blade is often the solution. The teeth grab individual fibers, creating a cleaner cut that seals the fabric edge. Consult our blade materials classification guide for a deeper technical analysis.

3. Proactive Maintenance Maximizes Blade Life and Performance

Even the finest blade will underperform without proper care. A reactive approach—waiting for a failure—guarantees downtime and wasted material. A scheduled, proactive maintenance routine is the hallmark of a world-class operation. This involves regular inspection for nicks, burrs, or microscopic edge rolling that degrade cut quality. Implementing a strict schedule for professional sharpening restores the factory edge geometry before excessive damage occurs, preserving the blade's core integrity through multiple life cycles.

Equally important is the care of ancillary components. The blade holder or anvil must be kept clean and perfectly aligned. A worn or misaligned holder will cause poor cutting performance and accelerated blade wear, nullifying your investment in a premium blade. Simple steps like keeping the cutting area free of debris and using the correct blade for the material (never forcing a blade to cut something it's not designed for) dramatically extend service intervals. For more details, explore our technical help resources.

4. Analyze Total Cost of Ownership for Smart Investment

The initial purchase price of a blade is a fraction of its true cost. Smart procurement decisions are based on Total Cost of Ownership (TCO), which evaluates performance and cost over the entire blade lifecycle. Calculate your Cost-Per-Meter or Cost-Per-Hour by factoring in the blade's operational lifespan, maintained cut quality, energy efficiency, and frequency of sharpening. A premium ShengAo blade, with its extended service life and consistent output, invariably delivers a lower TCO than a cheaper, inferior alternative.

Furthermore, quantify the staggering cost of unplanned downtime—lost production, missed deadlines, and labor costs during changeovers. Investing in durable, reliable blades from a trusted partner like ShengAo is an investment in continuous production and revenue protection. Leverage our manufacturer expertise; our engineering team provides actionable advice on selection, maintenance, and optimization, ensuring your operation remains competitive.

5. Conclusion: Choose Expertise, Choose ShengAo

In the fast-paced worlds of packaging and textiles, precision, speed, and reliability are non-negotiable. Circular blades, when expertly matched to the application and maintained with discipline, deliver on all three. By understanding the synergy between blade design, advanced metallurgy, proactive care, and true cost analysis, you can elevate your cutting operations from a necessary function to a strategic advantage. Don't let a suboptimal blade be the weak link in your production chain. Contact the ShengAo engineering team today for a personalized consultation to find the perfect circular blade solution for your unique challenges.