What to Look for in Industrial Circular Blades

What to Look for in Industrial Circular Blades

Table of Contents

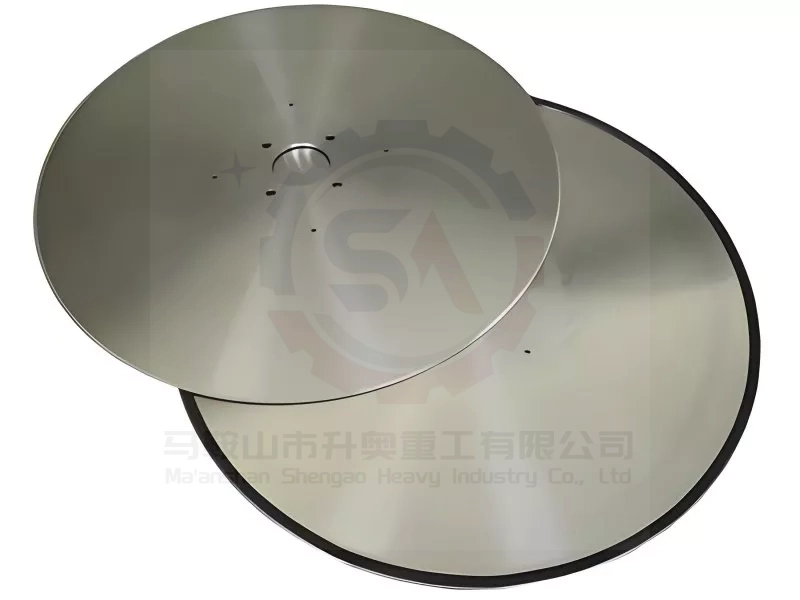

Selecting the optimal industrial circular blades is a critical decision that directly impacts productivity, cut quality, and your bottom line. Whether you're slicing paper, plastic film, metal foils, or composite materials, the right blade ensures clean cuts, minimizes waste, and extends intervals between replacements. This guide will walk you through the key factors—from blade material compatibility and edge geometry to hardness and advanced coatings—to help you choose circular blades that deliver peak performance and durability for your specific application.

1. Understand Your Cutting Needs

The foundation of selecting the right circular blade is a clear understanding of your cutting operation. The material you process dictates every other specification.

Soft, Fibrous Materials (e.g., Paper, Cardboard, Non-wovens): These require blades that are sharp and can maintain a fine edge to prevent tearing or fraying. A focus on sharpness retention and corrosion resistance is key.

Plastic Films & Flexible Packaging (e.g., PE, PP, BOPP): Cutting thin, flexible materials demands extremely sharp, often coated blades to achieve burr-free, sealable edges. Blades must resist material buildup and static.

Metals & Hard Composites (e.g., Aluminum foil, Copper strips, Laminates): These abrasive or hard materials require blades with exceptional wear resistance and hardness. Tungsten carbide or specially hardened steel blades are often necessary to maintain dimensional accuracy and edge integrity.

Defining your primary material, its thickness, and required production speed is the essential first step. For a deeper dive into applications, explore our guide on circular blade applications.

2. Blade Material and Coating

The core material defines the blade's fundamental capabilities. Selecting the right substrate and enhancing it with a coating can dramatically improve performance and lifespan.

| Material | Key Characteristics | Ideal For |

|---|---|---|

| High-Speed Steel (HSS) | Excellent toughness, good wear resistance, can be sharpened to a very fine edge. Balances performance and cost. | General-purpose cutting of paper, textiles, rubber, and some plastics. Learn more about HSS blades. |

| Tool Steel (D2, A8, M2) | High carbon and chromium content provides superior hardness and wear resistance after heat treatment. | Heavy-duty cutting of abrasive materials, corrugated board, and dense plastics. Resists deformation under load. |

| Solid Tungsten Carbide | Extreme hardness and wear resistance, maintains sharpness 10-20x longer than steel. Brittle and requires careful handling. | High-volume, precision slitting of films, foils, electronics materials, and abrasive non-wovens. Discover carbide blades. |

| Ceramic & Cermet | Exceptional heat and chemical resistance, extremely hard. Used in specialized, high-speed dry cutting applications. | Cutting advanced composites, carbon fiber, and materials where metal contamination must be avoided. |

Coatings: Applied like a thin skin, coatings such as Titanium Nitride (TiN), Titanium Carbo-Nitride (TiCN), or Diamond-Like Carbon (DLC) reduce friction, prevent material adhesion, and enhance surface hardness. They are especially valuable for sticky materials like adhesives or certain polymers, extending time between sharpening. Explore the benefits of specially coated blades.

3. Blade Edge Type and Design

The geometry of the cutting edge determines how the blade interacts with the material. The wrong edge type can cause poor cuts, excessive force, and premature wear.

Plain/Flat Edge: Features a smooth, continuous cutting bevel. It provides the cleanest, most precise cut for homogeneous materials like paper, film, and foil. It is the standard for most high-precision slitting operations.

Serrated/Toothed Edge: The edge has a patterned "teeth" design. Serrations grip the material, preventing slippage during the cut. This is crucial for cutting slippery materials like laminated films, textiles, or food products. They also reduce cutting force for thicker materials. See our range of serrated cutting blades.

Bevel Design (Single vs. Double):

Single-Bevel: Sharpened on one side only, creating a chisel-like edge. Ideal for scoring, perforating, or creating a clean shear cut against a counter blade.

Double-Bevel: Sharpened symmetrically on both sides. This is the most common design for rotary knives and slitters, offering a balanced cut and easier resharpening. Understand the differences with our guide on double bevel blades.

4. Blade Hardness and Wear Resistance

Hardness, typically measured on the Rockwell C scale (HRC), is a primary indicator of a blade's ability to resist wear and hold an edge. However, hardness must be balanced with toughness.

Low to Medium Hardness (HRC 45-55): Offers high toughness and resistance to chipping. Suitable for cutting irregular or contaminated materials where impact resistance is more important than extreme wear life.

High Hardness (HRC 58-62): The sweet spot for most industrial cutting applications. Provides excellent edge retention for continuous cutting of abrasive papers, plastics, and thin metals. Tool steels like D2 are often hardened to this range.

Very High Hardness (HRC 65+): The domain of tungsten carbide and ceramics. Essential for ultra-high-wear applications but requires perfect machine alignment and no shock loading to prevent brittle fracture.

The blade material classification plays the decisive role in achievable hardness. Advanced precision grinding and heat treatment processes at ShengAo ensure the specified hardness is consistently achieved throughout the blade.

5. Balancing Cost and Quality

While initial purchase price is a factor, the true cost of a blade includes its lifespan, cutting quality, and the downtime required for changeovers and sharpening.

Total Cost of Ownership (TCO): A premium blade made from superior material with an advanced coating may cost 50% more but can last 300% longer and produce consistently higher-quality cuts. This reduces changeover frequency, waste, and labor costs.

Resharpening Potential: High-quality blades are designed to be reground multiple times. Consider the cost and ease of resharpening. A blade that can be reliably resharpened in-house or by the manufacturer offers far greater long-term value than a disposable one.

Investing in blades from a reputable manufacturer like ShengAo, which offers stringent quality control, material traceability, and technical support, mitigates risk and ensures predictable performance. View our manufacturing process to see our commitment to quality.

6. Ensuring Machine Compatibility

The perfect blade is useless if it doesn't fit your machine. Compatibility is non-negotiable for safety and performance.

Physical Dimensions: Precisely match the outer diameter (OD), inner diameter (bore/ID), and thickness (width) to your machine's specifications. Even a minor discrepancy can cause vibration, poor cuts, or machine damage.

Mounting System: Confirm the blade is designed for your machine's mounting method (e.g., arbor, hub, cartridge). This includes matching any keyways, screw patterns, or clamping mechanisms.

Operating Parameters: Ensure the blade is rated for your machine's maximum operating speed (RPM) and can handle the intended material feed rate and tension.

Always consult your machine manual and the blade manufacturer's specifications. For custom or hard-to-find sizes, ShengAo's customized circular blade service can provide a perfect match. Our engineering support team is also available to assist with compatibility questions.

Conclusion

Choosing the right industrial circular blade is a systematic process that balances your material requirements with blade material science, design, and operational economics. By carefully evaluating your cutting needs, opting for the appropriate material and edge type, and prioritizing long-term performance over short-term savings, you can significantly enhance your production efficiency. The correct blade minimizes downtime, reduces waste, and delivers the consistent, high-quality cuts that your operation demands. Partnering with an experienced manufacturer ensures you have the expertise and product quality to keep your lines running smoothly.