What Are the Key Signs That Your Single Shaft Shredder Blades Need Replacing?

What Are the Key Signs That Your Single Shaft Shredder Blades Need Replacing?

Table of Contents

Is your shredder suddenly struggling, consuming more power, or producing inconsistent output? Ignoring the warning signs of worn Single Shaft Shredder Blades can lead to catastrophic downtime, damaged equipment, and skyrocketing operational costs. This guide is your essential diagnostic tool. We will clearly outline the critical physical, auditory, and performance indicators that signal an immediate blade replacement is due. From diminished cutting efficiency and unusual vibrations to increased energy bills and poor particle quality, learning to recognize these signs early can save you thousands in preventable repairs and lost productivity. Leverage ShengAo's expertise in precision blade manufacturing and technical support to make informed decisions and keep your operation running smoothly.

Reduced Cutting Efficiency: Visual & Performance Signs

The most direct sign of blade wear is a visible decline in performance. A sharp blade cuts cleanly and efficiently; a dull blade tears, crushes, and strains the entire system.

Longer Cycle Times: If processing the same material batch takes significantly longer than before, your blades are likely losing their edge. The shredder motor works harder to achieve the same result, indicating the blades are not shearing effectively.

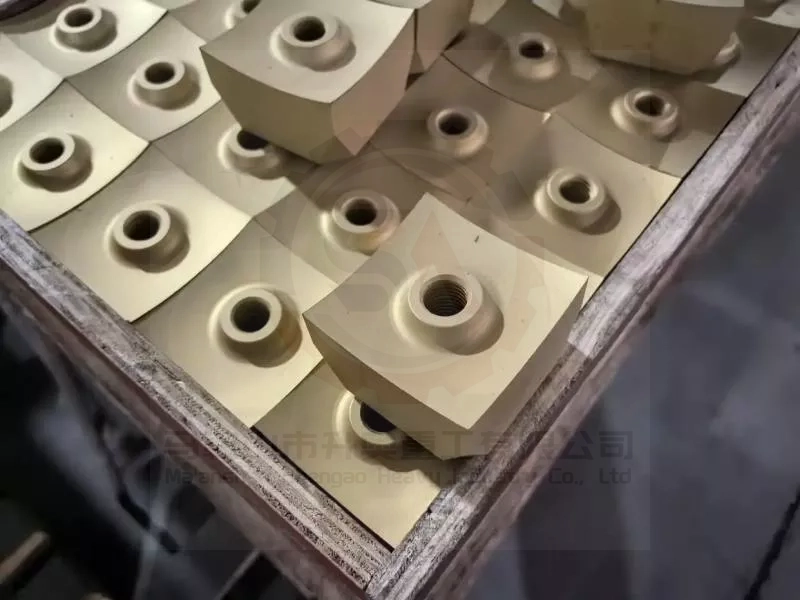

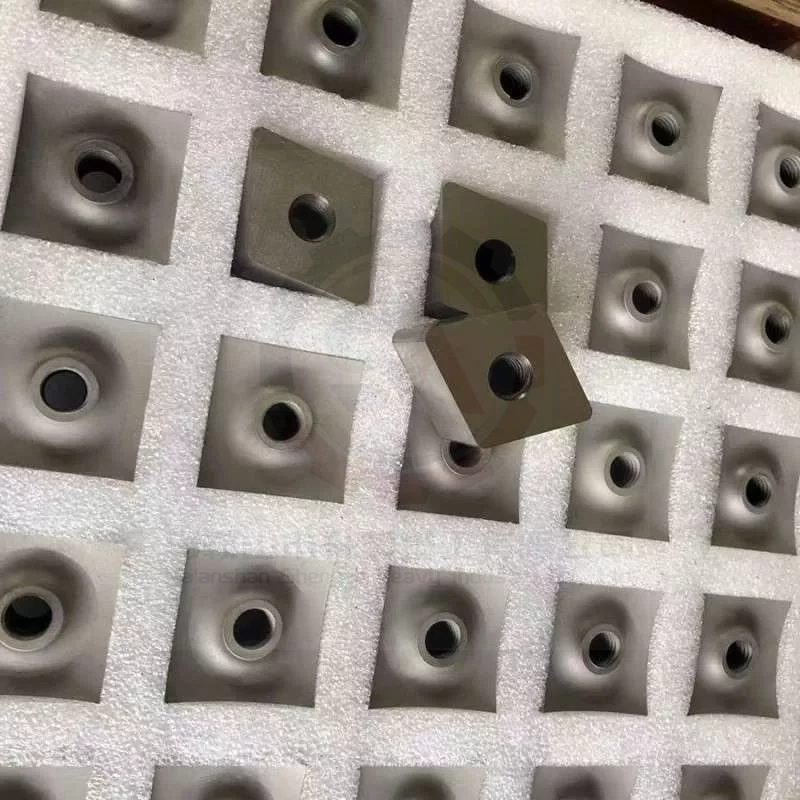

Visible Blade Wear & Damage: During routine inspection, look for these tell-tale signs:

- Rounded Edges: The sharp cutting edge is visibly worn down, rounded, or chipped.

- Cracks or Fractures: Stress fractures, especially near mounting holes or cutting tips, are a severe safety risk and demand immediate replacement.

- Excessive Grooving: Deep grooves or uneven wear patterns on the blade surface caused by abrasive materials.

- Corrosion or Pitting: Chemical reactions with certain materials can degrade the blade material, weakening its structure.

Material "Riding" the Rotor: Instead of being grabbed and pulled into the cutting chamber, material sits on top of the rotor or requires manual pushing. This indicates the blade's hook or cutting geometry is too worn to engage the feedstock properly. When performance drops, it's time to consult our Shredder Blade Guide for selection advice.

Unusual Noises & Vibrations

Your shredder has a familiar operational sound. Significant changes in this acoustic profile are urgent diagnostics.

Knocking, Grinding, or Screeching: These are not normal operational sounds. Knocking or banging often indicates a severely chipped blade striking the counter-blade or chamber wall. A persistent grinding noise suggests metal-on-metal contact due to misalignment from wear or a broken blade segment. High-pitched screeching can point to excessive friction from dull blades struggling to cut.

Excessive Vibration: While some vibration is normal, a noticeable increase that shakes the machine or surrounding structure is a critical alert. This is often caused by:

- Unbalanced Rotor: Uneven wear or damage to one or more blades throws the rotor off balance.

- Broken Blade Segments: A missing piece of a carbide tip or a cracked blade creates a heavy spot.

- Loose Mountings: Wear can elongate mounting holes, causing blades to loosen and vibrate.

Ignoring these sounds and vibrations risks major damage to the rotor bearings, shafts, and the machine frame itself. A proactive check can prevent this. Explore our Video Hub for maintenance tutorials.

Increased Energy Consumption

Your electricity bill can be a surprising indicator of blade health. Dull or damaged blades force the shredder's motor and drive system to work exponentially harder to achieve the same throughput.

Motor Overloads & Tripped Breakers: Frequent thermal overloads or circuit breaker trips are clear signs the motor is drawing excessive amperage (amps). This is a direct result of increased torque demand from inefficient cutting.

Monitoring Power Draw: Plants with energy monitoring systems will see a sustained rise in the kilowatt-hour (kWh) consumption of the shredder for the same tonnage processed. A spike of 15-30% is common with worn blades.

The Physics of Inefficiency: Sharp blades utilize a clean shearing action, which requires less force. Dull blades compress, deform, and tear material, which demands significantly more mechanical energy. This wasted energy converts into heat, further stressing the machine. Upgrading to advanced materials like Tungsten Carbide Blades can maintain lower energy use for longer.

Poor Output Quality & Inconsistent Particle Size

The quality of your output material is a direct report card on your blades' condition. Declining quality affects the value of your recyclate or the efficiency of downstream processes.

Excessive Fines & Dust: Worn blades don't cut; they crush and pulverize. This generates a higher percentage of fine particles and dust than specified, which can be undesirable for pelletizing, washing, or further processing.

Irregular Shred Size & "Strings": Instead of cleanly cut chips or granules, output may contain long, stringy strands of material (especially plastics or films) or wildly inconsistent particle sizes. This indicates the blades are snagging and tearing rather than cutting.

Contamination: Severely worn or chipped blades made of tool steel can begin to shed minute metal particles into the output stream, contaminating the recycled material. This is a critical quality control failure. For consistent output in applications like plastic pelletizing, blade sharpness is non-negotiable.

| Output Symptom | Likely Blade Issue | Impact on Downstream Process |

|---|---|---|

| High dust/fines content | Dull, rounded cutting edges | Poor extrusion, feeding problems, dust collection overload |

| Long, uncut strands | Worn hook geometry, large gaps | Wrapping in granulators, sorting system clogs |

| Metal flecks in output | Chipped or spalling blade material | Product contamination, equipment damage downstream |

| Inconsistent chip size | Uneven wear across blade set | Inefficient drying, combustion, or compression |

Escalating Maintenance Costs & Frequent Jamming

When blades are past their prime, they create a cascade of secondary problems that drive up operational costs.

Increased Frequency of Jams: Dull blades lack the positive "bite" to pull material in. This leads to more frequent bridging in the hopper or jamming in the cutting chamber. Each jam requires downtime for clearing, often involving manual labor and safety risks.

Accelerated Wear on Other Components: The strain doesn't stop at the blades. The entire drive train suffers:

- Bed Knives/Counter Blades: Wear rapidly as they grind against dull rotor blades.

- Bearings & Seals: Excessive vibration and load shorten their lifespan.

- Hydraulic Systems (on feed rams): Experience higher pressure cycles and potential for failure.

Rising Sharpening Costs: While sharpening services are cost-effective, there's a point of diminishing returns. If blades require sharpening too frequently or are so worn that significant material must be removed to restore an edge, their structural integrity and heat treatment are compromised. It becomes more economical to invest in new, durable blades from a trusted industrial blades manufacturer like ShengAo.

Conclusion: Proactive Replacement Strategy

Waiting for a complete failure is the most expensive maintenance strategy. By learning to recognize the key signs—reduced throughput, strange noises, higher energy use, poor output, and frequent jams—you can transition to a proactive, scheduled replacement plan. This approach minimizes unplanned downtime, protects your capital equipment, and ensures consistent product quality and operational efficiency.

Partnering with ShengAo provides more than just premium single shaft shredder blades. It gives you access to expert guidance on wear patterns, optimal replacement intervals for your specific material, and services like precision re-grinding to extend blade life. View your shredder blades as a critical performance investment. By monitoring their condition and acting on these warning signs, you secure maximum uptime, lower your total cost of ownership, and maintain a competitive edge in your recycling or size-reduction operations.