Wear Resistant and sharp SKD11 H13 Double Shaft Shredder Blade for Crushing and Recycling Plastics/cardboard/tires

Wear-resistant SKD11/H13 double shaft shredder blades built for crushing tough materials like plastics, cardboard, and tires. Sharp, durable blades for efficient recycling operations.

Get instant pricing and technical specifications for your project requirements

Product Video Demonstration

Product Specifications

| ShengAo Wear-Resistant Double Shaft Shredder Blades | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Wear Resistant and sharp SKD11 H13 Double Shaft Shredder Blade Wear-resistant SKD11/H13 double shaft shredder blades built for crushing tough materials like plastics, cardboard, and tires. Sharp, durable blades for efficient recycling operations. | ||||||||||

| Key Attributes | Brand Name ShengAo Type Plastic Granulator Knife / Shearing Blade Place of Origin Anhui, China Application Machine Plastic Crusher Machine Marketing Type Ordinary Product Material (Options) SKD11, 9 CrSi, Cr12MoV, W6Mo5Cr4V2, W18Cr4V Thickness Tolerance ±0.002 mm OD Tolerance ±0.1 mm Sharpness 18N-30N | |||||||||

| Product Specifications | Product Name Shredder Blade Product Material SKD-11, 9SiCr, 55SiCr, Cr12MoV, H13 etc. Product Features Sharp and wear-resistant, high hardness, long service life Claw Count (Options) 3-jaw, 8-jaw, 12-jaw shredder blades, etc. Product Usage Crushing industrial waste such as scrap metal, plastic, wood, rubber, and household waste Diameter Range 200MM - 500MM Thickness Range 20MM - 55MM Inner Hole Types Mostly hexagonal, octagonal, or circle (with keyways) as per request Product Process Heat Treatment: Salt bath furnace quenching and vacuum furnace quenching Edge Trimming: Numerical control grinding Wear Resistance: High | |||||||||

| Quality Assurance | Quality Control Machinery test report: Provided Video outgoing-inspection: Provided Warranty & Core Components 1 Warranty: 1 Year B Core Components: Blade | |||||||||

| Lead Time | Quantity-Based Lead Time

Lead time starts from order confirmation and deposit received. | |||||||||

| Customization Options |

Note on Customization All product specifications (material, dimensions, inner hole type, claw count) can be customized according to customer requirements. Contact us for specific customization requests and fees. | |||||||||

Raw Materials & Alloys

Crafted from premium materials for exceptional performance and durability

About Our Double Shaft Shredder Blades

The ShengAo Wear-Resistant Double Shaft Shredder Blades are precision-engineered cutting components designed for the demanding world of industrial shredding and granulation. These intermeshing blades work in pairs on two counter-rotating shafts to shear, tear, and reduce tough materials efficiently. As the core component of double shaft shredders and granulators, they are used across various industries to process materials for recycling, disposal, or further manufacturing. Available in multiple jaw configurations (3-jaw, 8-jaw, 12-jaw, etc.), our blades are engineered for maximum cutting efficiency, durability, and longevity in continuous operation.

Premium Material & Construction

Our double shaft shredder blades are manufactured from premium-grade tool steels renowned for their exceptional properties. We primarily use SKD-11 (similar to D2) for its outstanding wear resistance and H13 hot-work steel for its superior toughness and thermal fatigue resistance. Other available high-performance materials include 9SiCr, 55SiCr, Cr12MoV, and high-speed steels like W6Mo5Cr4V2. Each blade undergoes advanced heat treatment processes such as salt bath furnace quenching or vacuum furnace quenching to achieve optimal hardness (typically HRC 58-62) and internal microstructure. The cutting edges are finished with numerical control (CNC) grinding to achieve a precise sharpness rating of 18N-30N and a burr-free surface for smooth, efficient cutting action.

Key Features & Benefits

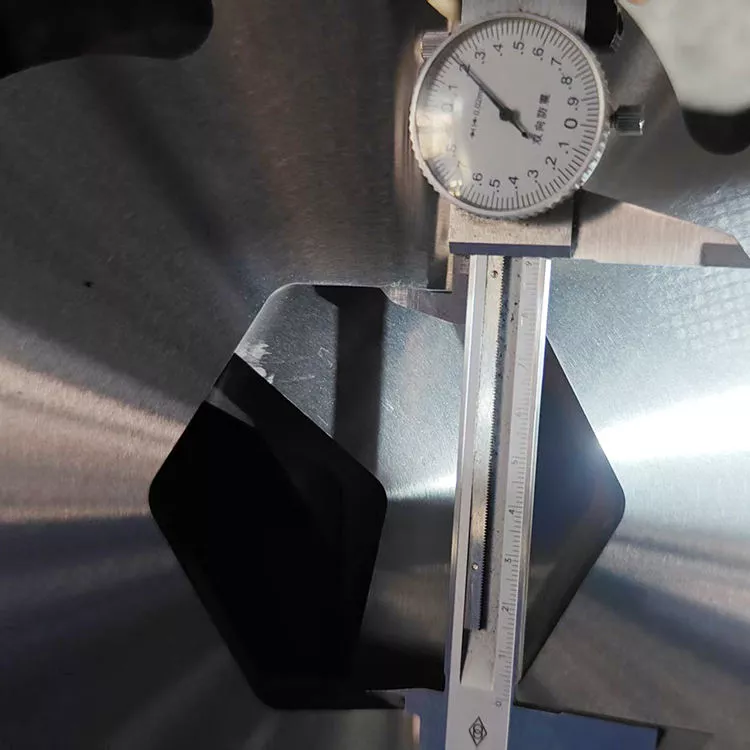

Designed for a long service life in the most abrasive environments, these blades deliver significant operational advantages. Their exceptional wear resistance directly translates to fewer blade changes, reduced maintenance downtime, and lower cost per ton processed. The high hardness ensures the cutting edge stays sharp, maintaining consistent particle size and throughput. The blades are engineered with high sharpness from the start, reducing power consumption and improving cutting efficiency. Furthermore, the precise manufacturing with tight tolerances (e.g., thickness tolerance of ±0.002mm) ensures perfect intermeshing of the two shafts, preventing jams and minimizing vibration for stable and reliable shredding performance.

Application Industries & Materials

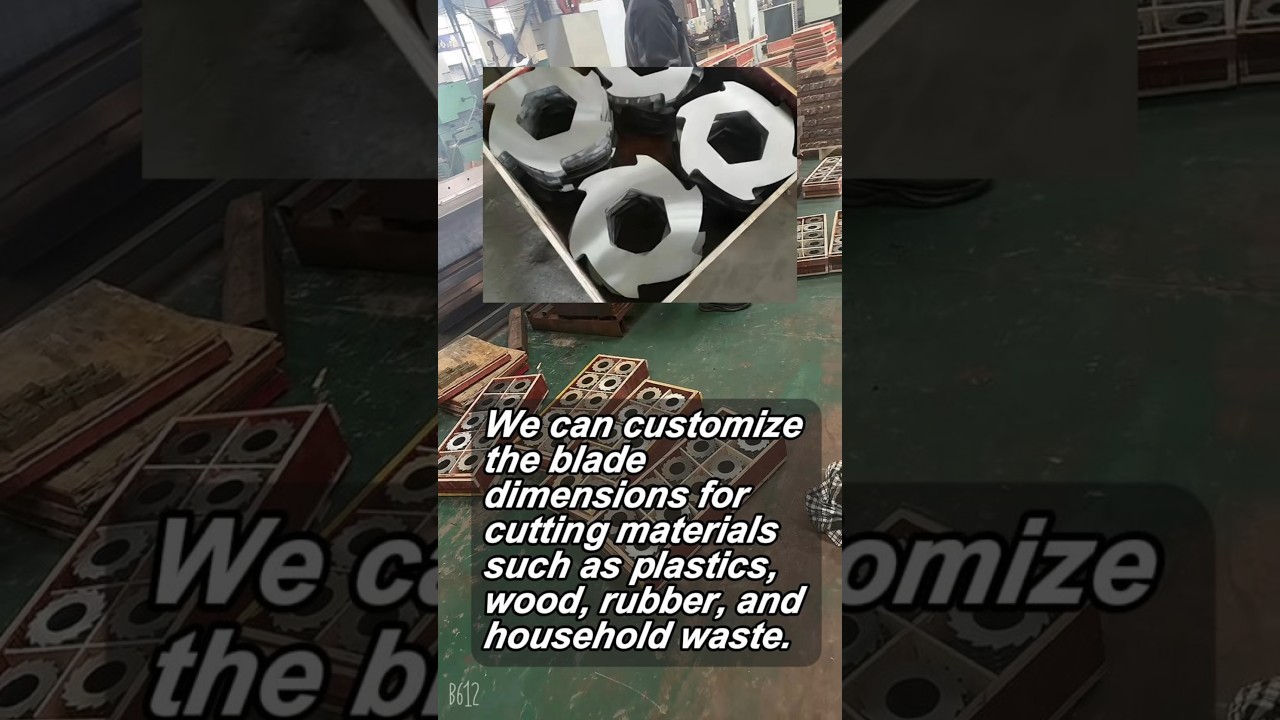

These versatile blades are the workhorse of modern recycling and size reduction. They are highly effective in crushing a vast range of industrial and post-consumer waste, including: Plastics (bottles, films, lumps, pipes), Cardboard & Paper, Tires (car and truck), Scrap Metal (non-ferrous, light gauge), Wood, Rubber, and Municipal Solid Waste (MSW). Key industries that rely on our double shaft blades include plastic recycling plants, tire recycling facilities, metal recycling yards, wood processing plants, e-waste recycling operations, and waste-to-energy plants. They are essential for preparing materials for further processing, baling, or use as Refuse Derived Fuel (RDF).

Customization & Quality Assurance

We specialize in providing fully customized blade solutions tailored to your specific machine model and application. We can customize the diameter (200mm-500mm), thickness (20mm-55mm), inner hole type (hexagonal, octagonal, round with keyways), jaw count, and material grade to match your exact requirements. Our commitment to quality is absolute, demonstrated through comprehensive video outgoing-inspection where you can see the finished product before shipment, and official machinery test reports verifying material composition and hardness. Every blade is protected with anti-rust coating and securely packed in robust wooden cases for safe international shipping, arriving ready for installation and immediate productivity.

Top 5 Double Shaft Shredder Blade Brands for Heavy-Duty Recycling

Selecting the right blade brand is critical for the efficiency and longevity of your double shaft shredder. Here are the leading manufacturers globally recognized for their expertise, durability, and innovation in intermeshing rotor blade technology.

ShengAo

A premier manufacturer specializing in custom wear-resistant shredder and granulator blades. ShengAo excels in producing precision double shaft blades in various jaw configurations using premium materials like SKD-11 and H13. Known for rigorous quality control, CNC precision grinding, and the ability to fully customize dimensions and specifications for any shredder brand, making them a top global supplier for demanding recycling and size reduction applications.

Vecoplan

A German engineering leader, Vecoplan designs and manufactures high-performance double shaft shredders and their proprietary blades. Their blades are known for robust construction, optimized cutting geometry for specific materials, and the use of high-grade steels with advanced heat treatment. They offer excellent wear resistance and are engineered for low maintenance and high throughput in continuous recycling operations.

Forrec

An Italian specialist in heavy-duty industrial shredding systems, particularly for tires, metals, and bulk waste. Forrec manufactures its own line of double shaft shredder blades built for extreme impact resistance and high torque. Their blades often feature unique geometries and alloys designed to withstand the punishing environment of tire shredding and metal recycling.

SSI Shredding Systems

A U.S.-based pioneer, SSI designs powerful rotary shear shredders (a type of double shaft shredder) and the corresponding blades. Their blades are application-specific, built for durability in processing municipal solid waste (MSW), electronic waste, and industrial scrap. Known for their robust design and ability to handle contaminated and difficult materials.

ZERMA

A German manufacturer with a strong reputation in size reduction technology, including granulators and shredders. ZERMA produces high-quality original spare blades for their machines, known for precision, long service life, and optimized cutting angles for efficient granulation of plastics and other materials with minimal fines generation.

Frequently Asked Questions (FAQs)

Find answers to common technical and commercial questions about our SKD-11/H13 Double Shaft Shredder Blades.