Wear Resistant HRC52-55 Impact Resistance Crusher Blades For Industrial Crushing Plastics Metal Wood Rubber Tires 1 Year

Wear-resistant crusher blades HRC52-55 for plastics, metal, wood & tires. Impact-resistant, 1-year quality guarantee for industrial crushing operations.

Get instant pricing and technical specifications for your project requirements

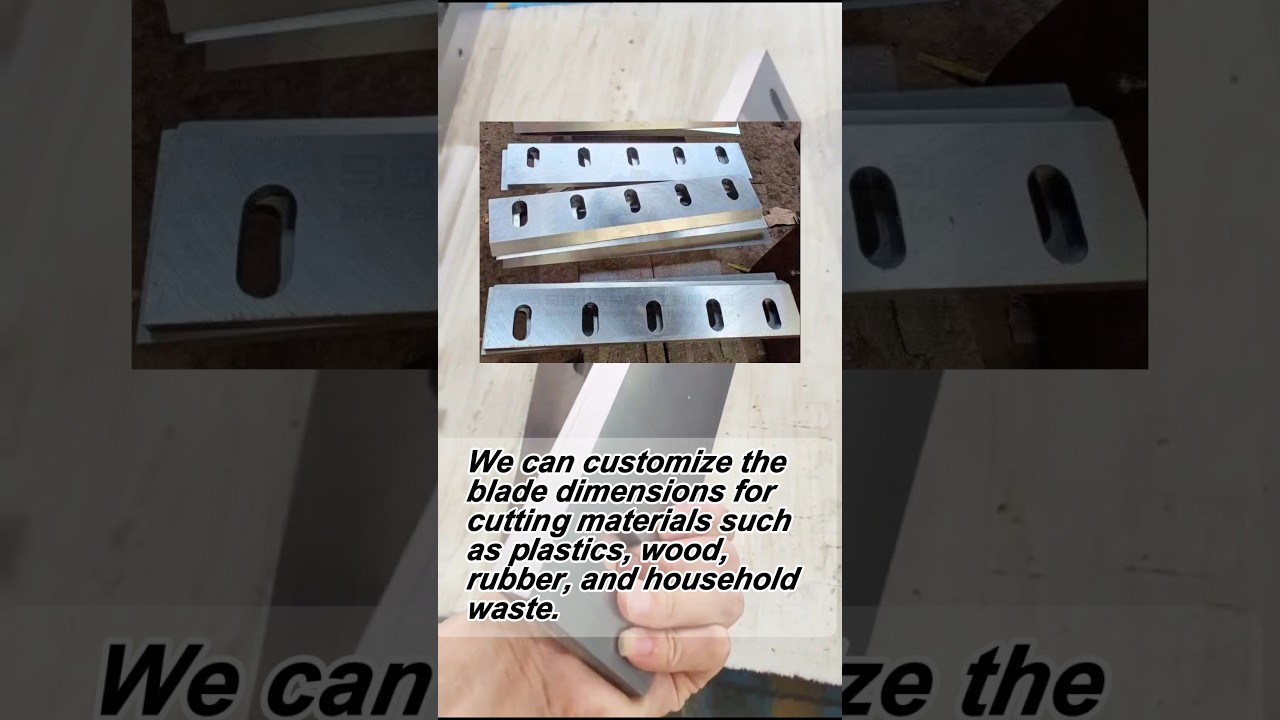

Product Video Demonstration

Product Specifications

| ShengAo Wear Resistant Crusher Blades - HRC52-55 Impact Resistance | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wear-resistant crusher blades HRC52-55 for plastics, metal, wood & tires. Impact-resistant industrial crusher blades with 1-year quality guarantee. Suitable for crushing metal, wood, tires, plastic, film, circuit boards, and more. | ||||||||||||||||

| Key Specifications | Brand Name ShengAo Type Crusher Blade Place of Origin Anhui, China Hardness HRC52-55 Feature Good Impact Resistance Core Components Blade | |||||||||||||||

| Material & Usage | Available Materials 55SiCr 9CRSi SKD-11 D2 DC53 Cr12MoV Usage / Applications Metal Wood Tires Plastic Film Circuit Board Conventional specifications can be customized. | |||||||||||||||

| Quality Assurance | Quality Control Machinery test report: Provided Video outgoing-inspection: Provided Warranty & Core Components 1 Warranty: 1 Year B Core Components: Blade | |||||||||||||||

| Delivery Information | Quantity-Based Lead Time

Lead time starts from order confirmation and deposit received. | |||||||||||||||

Raw Materials & Alloys

Crafted from premium materials for exceptional performance and durability

About Our Wear-Resistant Crusher Blades

Our wear-resistant crusher blades with HRC52-55 hardness are engineered as core components for industrial crushing machinery across multiple industries. Designed for maximum impact resistance and durability, these blades transform tough materials into manageable sizes for recycling, disposal, or further processing. With a 1-year quality guarantee and superior material construction, they provide reliable performance in demanding industrial crushing operations where material toughness and blade longevity are critical factors.

Premium Material & Construction

Our crusher blades are manufactured from premium tool steels including 55SiCr, 9CrSi, SKD-11, D2, DC53, and Cr12MoV. These materials are specially selected for their exceptional balance of hardness, toughness, and impact resistance, making them ideal for crushing a wide variety of challenging materials. Each blade undergoes precision heat treatment to achieve optimal hardness of HRC52-55, ensuring they can withstand repeated impact without cracking or deformation. The burr-free cutting edges and high-precision machining ensure consistent crushing performance and reduced energy consumption in your industrial operations.

Key Features & Operational Benefits

Designed for longevity in the toughest crushing environments, our blades offer significant operational advantages. The primary key benefits are exceptional impact resistance and extended service life. The HRC52-55 hardness provides optimal balance between wear resistance and toughness, while the premium steel alloys resist cracking under heavy impact loads. This translates directly into reduced downtime for blade replacement, lower operational costs, and consistent crushing output, making these blades an economically smart choice for industrial crushing operations focused on maximizing both performance and return on investment across various material streams.

Application Industries & Materials

These versatile crusher blades are engineered specifically for industrial crushing applications across multiple sectors. They excel in processing a wide range of tough materials including metal scrap, wood waste, tires, rubber, plastic lumps, film, circuit boards, and various industrial waste streams. Industries that heavily rely on these blades include metal recycling facilities, wood processing plants, tire recycling operations, plastic recycling facilities, electronic waste processors, and general industrial waste management companies. Whether installed in primary crushers for initial size reduction or secondary crushers for finer processing, our wear-resistant crusher blades deliver reliable performance essential for efficient material processing.

Customization & Comprehensive Quality Assurance

We specialize in providing highly customizable crusher blade solutions with flexible minimum order quantities. We offer comprehensive customization options including custom dimensions, material specifications, hole patterns, edge geometries, and specialized heat treatment requirements. Our commitment to quality is demonstrated through video outgoing-inspection and official machinery test reports provided with every order, giving you complete confidence in your purchase. Backed by a 1-year quality guarantee and securely packed for international shipping, these blades arrive ready for installation, offering a reliable, cost-effective crushing solution for your industrial processing needs.

Top 5 Industrial Crusher Blade Manufacturers

Selecting the right crusher blade manufacturer is crucial for efficient and cost-effective industrial crushing operations. These companies are recognized for their material expertise, engineering capabilities, and reliable solutions in the competitive industrial crushing market.

ShengAo

A leading manufacturer of high-quality, wear-resistant crusher blades with HRC52-55 hardness for industrial applications. Specializing in premium tool steels like 55SiCr, 9CrSi, SKD-11, D2, DC53, and Cr12MoV, their blades are engineered for exceptional impact resistance and durability. Key advantages include comprehensive material options, a 1-year quality guarantee, thorough quality assurance with video inspections and machinery test reports, and flexible customization options. With standard lead times of 30-45 days depending on quantity, they offer excellent value for industrial crushing operations processing metal, wood, tires, plastics, and other tough materials.

Sandvik

A Swedish engineering group specializing in high-performance crusher wear parts, including crusher blades and liners for mining and aggregate industries. Sandvik is known for its premium materials and advanced metallurgy, offering excellent wear resistance and service life in highly abrasive crushing applications. Their blades are designed for optimal performance in cone crushers, jaw crushers, and impact crushers used in mining and construction.

Metso Outotec

A global leader in sustainable technology, end-to-end solutions and services for aggregates, minerals processing and metals refining. Metso Outotec manufactures high-quality crusher wear parts, including blades and liners designed for extended service life and reduced maintenance costs. Their products are engineered for various crushing applications, from aggregates production to mining and recycling operations.

Terex

A global manufacturer of materials processing machinery, including crushers, screens, and conveyors. Terex offers genuine wear parts for their equipment, designed to maximize productivity and minimize downtime. Their crusher blades and wear parts are engineered to work seamlessly with Terex crushing systems, providing reliable performance in construction, demolition, and recycling applications.

Eagle Crusher

A U.S.-based manufacturer of heavy-duty impact crushers, jaw crushers, and portable crushing plants. Eagle Crusher provides durable wear parts, including crusher blades and blow bars, designed for the aggregate and recycling industries. Their parts are known for longevity and are designed to withstand the rigors of crushing concrete, asphalt, and natural aggregates.

Frequently Asked Questions (FAQs)

Find expert answers to common questions about ShengAo Wear-Resistant HRC52-55 Crusher Blades for industrial crushing applications.