The Ultimate Single Shaft Blade for Plastic Recycling

The Ultimate Single Shaft Blade for Plastic Recycling

Table of Contents

1. Core Engineering for Unbeatable Performance

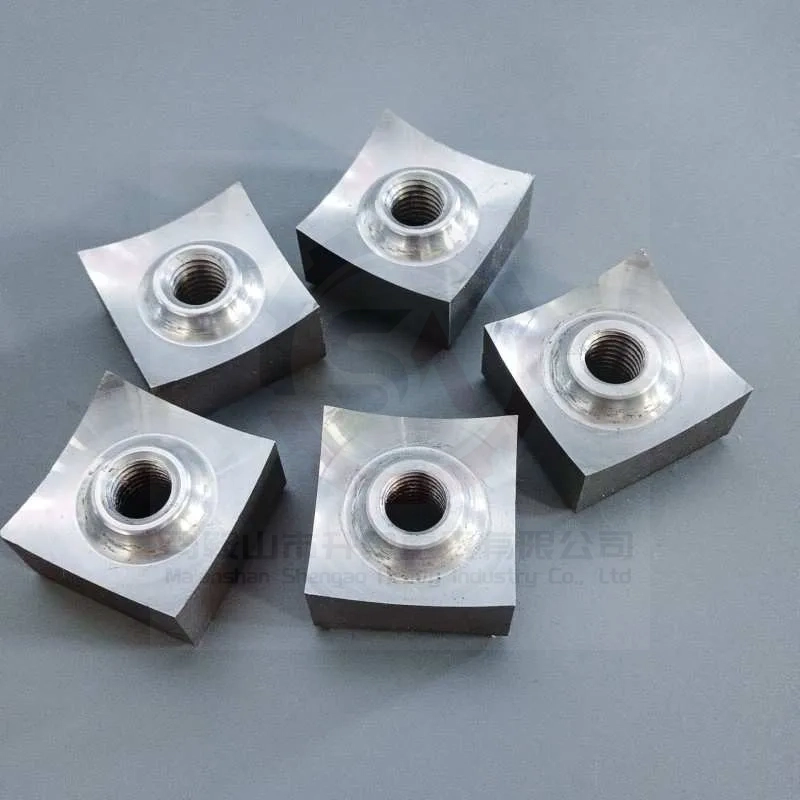

The superiority of a shredder blade is not an accident; it's the result of meticulous engineering at every stage. ShengAo's single shaft shredder blades are built on a foundation of three non-negotiable pillars: precision, hardness, and surface enhancement.

First, CNC Precision Machining ensures every blade is geometrically perfect. This eliminates vibration, reduces uneven wear, and guarantees that each cutting edge engages the material optimally. This precision translates directly to consistent particle size and smoother machine operation.

Second, achieving a hardness of HRC 58-62 is a critical balance. It provides exceptional resistance to abrasion from reinforced plastics and glass-filled materials, yet retains enough toughness to withstand impact without chipping. This specific range is the sweet spot for enduring the punishing environment of plastic shredding.

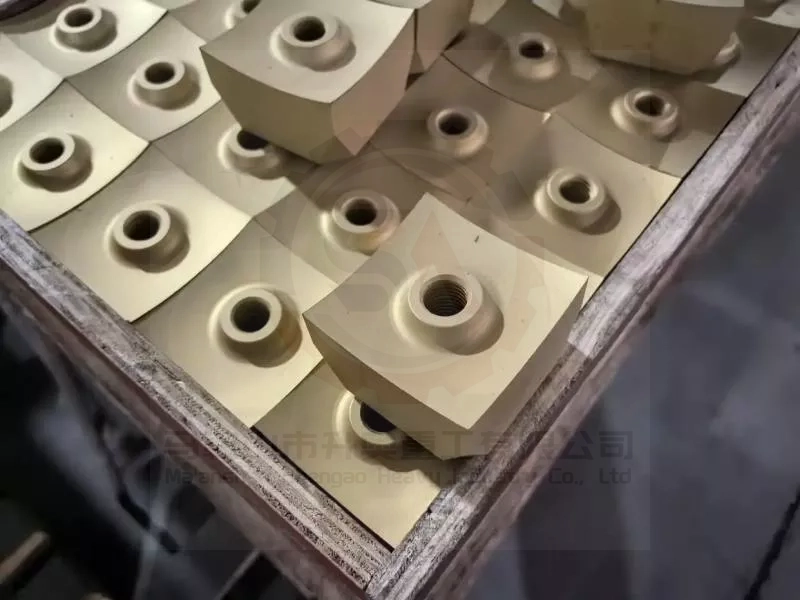

Third, the proprietary Titanium-based Coating is a game-changer. This ultra-hard, low-friction surface treatment does more than just protect the base material. It significantly reduces heat buildup from friction, prevents plastic residue from adhering to the blade (anti-stick properties), and acts as a sacrificial layer, extending the core steel's life. This trio of features—precision, core hardness, and smart coating—works synergistically to deliver the promised 5x lifespan increase.

2. Versatility Across Plastic Types & Applications

A common misconception is that one blade fits all plastics. In reality, different polymers and forms present unique challenges, from the abrasive nature of PET bottles to the tough, stringy nature of HDPE film. The adaptability of ShengAo's single shaft system lies in customizable geometry and material specification tailored to these challenges.

Whether you're processing post-consumer bottles, industrial purge, agricultural film, or complex composites, the blade's hook angle, cutting edge configuration, and material grade can be optimized. For instance, a sharper, more aggressive hook is ideal for tearing through bulky items, while a specific edge finish is better for cleanly slicing film without wrapping.

The following table illustrates how our engineered blades tackle diverse plastic streams:

| Plastic Type/Form | Primary Challenge | Recommended ShengAo Blade Configuration | Key Benefit |

|---|---|---|---|

| PET Bottles, HDPE Containers | Abrasion from labels, dirt, and glass fibers; high-volume processing. | Premium D2/SKD-11 Steel with Titanium Coating. Standard hook geometry. | Maximum wear resistance maintains sharpness, ensuring high throughput and clean flakes. |

| LDPE/HDPE Film, Bags | Material wrapping around the rotor, heat buildup, inconsistent cut. | Polished & Coated Surface. Optimized hook design for anti-winding. | Reduces adhesion and friction, prevents melt-back, and ensures steady feeding. |

| PP/PE Pipes, Profiles | High impact load, potential for blade chipping. | High-Toughness Alloy Steel (HRC 58-60). Reinforced blade design. | Absorbs shock loads, prevents catastrophic failure, and handles bulky rigid items. |

| Reinforced Plastics (GF, CF) | Extremely abrasive, rapidly dulls standard blades. | Tungsten Carbide Tipped or Inlaid Options. Special hardened matrix. | Unmatched abrasion resistance. Outlasts standard steel blades by 10x or more in these applications. |

3. Maximizing Lifespan & Minimizing Operational Cost

The true cost of a blade isn't its purchase price, but its total cost of ownership (TCO). Frequent blade changes cripple productivity through unplanned downtime, labor costs for replacement, and lost throughput. ShengAo's blades are engineered from the outset for maximum uptime and predictable maintenance.

The extended 5x service life is achieved through the combination of factors previously detailed. This means fewer changeovers, less machine downtime, and more tons processed per blade set. Furthermore, the robust construction and premium materials make our blades ideal candidates for professional blade restoration and sharpening services. Instead of discarding a worn blade, it can be professionally reconditioned multiple times, restoring its cutting profile and performance at a fraction of the cost of a new blade.

This approach transforms your blade from a consumable into a long-term, repairable asset. By scheduling maintenance around predictable sharpening cycles, you move from reactive, costly stoppages to efficient, planned production management, directly boosting your bottom line.

4. Choosing Your Ultimate Blade

To unlock the full potential of an ultimate single shaft blade, selection must be application-specific. The "best" blade is the one perfectly matched to your machine, material, and desired output size. Partnering with an expert like ShengAo is crucial for this decision.

Key factors to analyze include:

- Material Composition: Are you shredding pure PP, contaminated PET, or glass-filled nylon? Abrasion resistance is the top priority for filled materials.

- Feedstock Form: Bulk vs. film, thick-walled vs. thin. This dictates the optimal hook geometry and rotor configuration to prevent bridging or wrapping.

- Desired Output Size: The size and shape of the screen underneath the rotor determine the final particle dimension. Blade design works in tandem with screen size.

- Machine Specifications: RPM, power, and rotor diameter are fixed parameters that the blade must be designed to complement.

Our technical team at ShengAo doesn't just sell blades; we provide cutting solutions. By reviewing your specific parameters, we can recommend or custom-engineer the exact single shaft shredder blade configuration that will maximize your efficiency and return on investment.

Final Thoughts

In the demanding world of plastic recycling, settling for ordinary blades leads to extraordinary costs and headaches. The ultimate single shaft blade is defined by precision engineering that fights wear at every level: through CNC accuracy, optimized core hardness, and advanced protective coatings. ShengAo's commitment to this philosophy delivers proven results—dramatically extended service life, consistent product quality, and a lower true operational cost. Stop replacing blades and start optimizing your process. Contact ShengAo today for a consultation and let us engineer the ultimate blade solution for your recycling success.