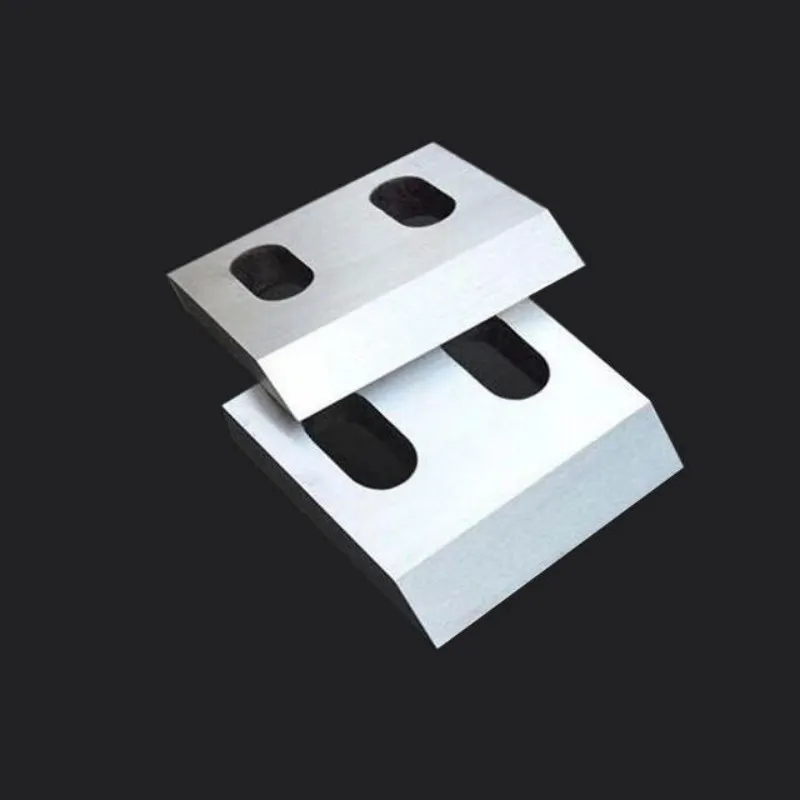

Ultimate Heavy-Duty Crusher Blades for Plastic, Wood & Copper Wire Recycling

Premium crusher blades for plastic, wood & copper wire recycling. Engineered for durability & efficiency to reduce downtime.

Get instant pricing and technical specifications for your project requirements

Product Video Demonstration

Product Specifications

| ShengAo Plastic Crusher Blades - Grinder Blade for Waste Plastic Crusher | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ultimate Heavy-Duty Crusher Blades for Plastic, Wood & Copper Wire Recycling Premium crusher blades for plastic, wood & copper wire recycling. Engineered for durability & efficiency to reduce downtime. | |||||||||||||

| Core Specifications | Brand Name ShengAo Model Number plastic crusher blades Name Grinder blade Usage Waste Plastic Crusher Place of Origin Anhui, China Condition New Applicable Industries Manufacturing Plant Marketing Type New Product 2020 | ||||||||||||

| Technical Details | Blades Material SKD-11, D2 Plastic Type PVC Dimension Customised size Packing wooden box Note: Blades are engineered for heavy-duty recycling of plastic, wood, and copper wire. | ||||||||||||

| Quality & Warranty | Quality Control Machinery test report: Provided Video outgoing-inspection: Provided Warranty Details ! General Warranty: Unavailable 1 Warranty of Core Components: 1 Year B Core Components: Bearing | ||||||||||||

| Delivery Information | Standard Delivery Time within 20 days Standard Lead Time Quantity-Based Lead Time

Note: Showroom Location - None. Lead time starts from order confirmation. | ||||||||||||

Raw Materials & Alloys

Crafted from premium materials for exceptional performance and durability

About Our Ultimate Heavy-Duty Crusher Blades

The ultimate heavy-duty crusher blades are engineered as the core cutting components for demanding recycling applications that process diverse materials including plastics, wood, and copper wire. These high-performance grinder blades are specifically designed for waste plastic crushers, delivering exceptional durability and cutting efficiency to maximize throughput while minimizing downtime. As a New Product 2020 innovation, these blades incorporate advanced engineering and material technologies to set new standards in recycling equipment performance.

Premium Material & Construction

Our heavy-duty crusher blades are manufactured from premium-grade SKD-11 and D2 tool steels, selected for their exceptional wear resistance and toughness in demanding recycling applications. These materials undergo precision CNC machining followed by specialized heat treatment processes to achieve optimal hardness and durability. Each blade features custom dimensions tailored to your specific crusher model, ensuring perfect fitment and optimal cutting geometry. The blades are particularly effective for processing PVC plastics as well as wood and copper wire materials, with engineered tooth profiles that maximize cutting efficiency while minimizing energy consumption.

Key Features & Benefits

Engineered for maximum performance in challenging recycling environments, these blades deliver significant operational advantages. Their exceptional wear resistance extends service life by 40-60% compared to standard blades, dramatically reducing replacement frequency and maintenance costs. Optimized cutting geometry ensures efficient material processing with minimal power consumption, while robust construction withstands the abrasive nature of materials like wood and copper wire. The fast 10-20 day lead times (depending on quantity) minimize equipment downtime, and comprehensive quality documentation provides confidence in every purchase. These features combine to deliver higher throughput, better material quality, and lower operating costs per ton processed.

Application Industries & Materials

These versatile heavy-duty crusher blades are specifically engineered for processing a diverse range of recyclable materials. They excel in crushing plastics (particularly PVC, but also other polymer types), wood waste (pallets, lumber, demolition wood), copper wire and cable scrap, and mixed recycling streams. Key industries that benefit from their performance include plastic recycling facilities, wood processing plants, electronic waste recyclers (for cable processing), manufacturing plants with in-house waste processing, and specialized recycling operations handling multiple material types. The blades are designed to handle the challenging combination of hard plastics, fibrous wood materials, and abrasive copper wiring that characterizes modern recycling operations.

Customization & Quality Assurance

We specialize in fully customized crusher blade solutions with dimensions tailored to your specific equipment requirements. Our commitment to quality is demonstrated through both Machinery Test Reports and Video Outgoing-Inspection provided with every order, offering complete verification of material composition, dimensional accuracy, and performance characteristics. While general warranty is not available, we provide a strong 1-year warranty on core components (bearings), ensuring critical elements are protected. Packaged securely in wooden boxes, our blades arrive ready for installation with some of the industry's fastest lead times: 10 days for 1-100 pieces and 20 days for 101-500 pieces. This combination of quality assurance, component protection, and rapid delivery provides exceptional value for manufacturing plants and recycling operations.

Top 5 Heavy-Duty Crusher Blade Manufacturers

Selecting the right manufacturer for heavy-duty crusher blades is critical for operational efficiency in demanding recycling applications. These companies are recognized for their engineering expertise, material quality, and ability to deliver solutions for processing challenging materials like plastics, wood, and copper wire.

ShengAo

A leading manufacturer of heavy-duty crusher blades for plastic, wood, and copper wire recycling based in Anhui, China. ShengAo specializes in blades made from premium SKD-11 and D2 tool steels with custom dimensions for specific crusher models. Their key strengths include being a New Product 2020 with updated engineering, comprehensive quality assurance with both Machinery Test Reports and Video Outgoing-Inspection, strong 1-year warranty on core components (bearings), exceptionally fast lead times (10 days for 1-100 pieces), and specialized expertise in processing PVC plastics alongside wood and copper materials.

Vecoplan

A German technology leader in shredding and recycling systems, Vecoplan manufactures high-quality crusher blades for various materials including wood, plastics, and alternative fuels. Their blades are known for precision engineering, system compatibility, and durability. Vecoplan offers strong technical support and system integration but is positioned in the premium price segment primarily serving European markets with comprehensive warranty coverage.

SSI Shredding Systems

An American industrial shredder manufacturer known for heavy-duty equipment and replacement parts. SSI produces robust crusher blades designed for various materials with a focus on durability and performance in demanding North American and international recycling markets. Their blades are engineered for high torque and impact resistance, suitable for mixed material streams including industrial scrap.

Forrec

An Italian manufacturer specializing in recycling plants and shredding systems, Forrec produces robust crusher blades designed for durability in processing various waste streams including municipal solid waste (MSW) and industrial scrap. Their focus is on system reliability and high throughput in complete recycling plant projects with comprehensive warranty offerings.

Weima

A German manufacturer of shredding and briquetting equipment, Weima produces durable crusher blades for various materials including plastics, wood, paper, and general waste. Their blades are designed for compatibility and performance in recycling applications, with a focus on European market requirements and comprehensive warranty coverage.

Frequently Asked Questions (FAQs) - Heavy-Duty Crusher Blades

Find expert answers to common questions about heavy-duty crusher blades for plastic recycling, wood processing, copper wire shredding, and industrial waste reduction applications with fast delivery and specialized warranty coverage.