Tungsten Carbide Hard Metal Crusher Blades - Long-Lasting Industrial Shredder Blades for Plastic Film

Industrial-grade Tungsten Carbide Crusher Blades for plastic shredders. High wear resistance, long-lasting sharpness for plastic film, bottles & waste.

Get instant pricing and technical specifications for your project requirements

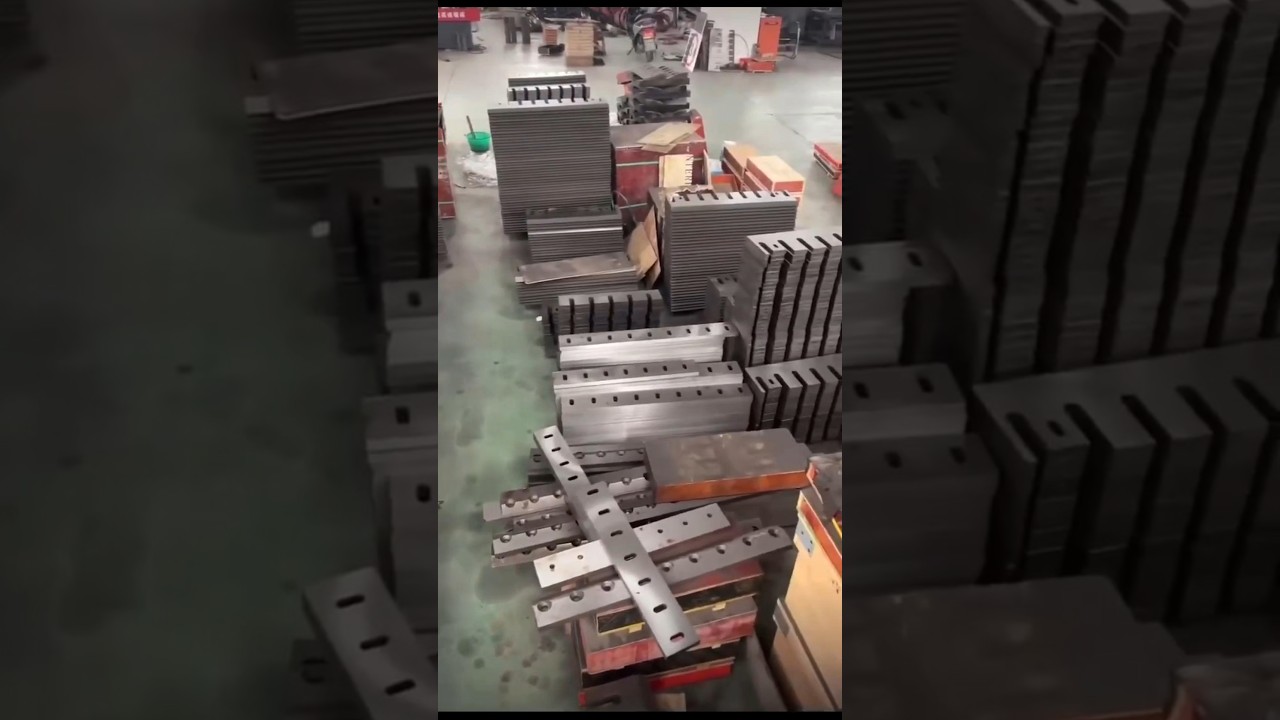

Product Video Demonstration

Product Specifications

| ShengAo Tungsten Carbide Crusher Blades - Industrial Shredder Blades | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Industrial-grade Tungsten Carbide Crusher Blades for Plastic Shredders High wear resistance, long-lasting sharpness for plastic film, bottles & waste. Designed for heavy-duty recycling applications. | |||||||||||||

| Key Attributes | Brand Name ShengAo Type Shredder Blade Place of Origin Anhui, China Condition New Application Shredder Blade And Knives for Plastic, Rubber, Metal, Waste Recycling Applicable Industries Manufacturing Plant, Machinery Repair Shops, Retail Core Components Blade Edge | ||||||||||||

| Design & Customization | Design Adjusted According To Your Requirement Knife Edge Adjusted According To Your Requirement Thickness Customized Thickness Available All design aspects can be tailored to meet specific machinery and material requirements. | ||||||||||||

| Quality Assurance | Inspection & Reports Machinery test report: Not Available Video outgoing-inspection: Provided Warranty & Support 6 Warranty: 6 Month WC Material: Tungsten Carbide | ||||||||||||

| Lead Time | Production Lead Time Based on Order Quantity

Lead time calculated from order confirmation and deposit receipt. | ||||||||||||

| Customization Options |

Note: Customization options available for bulk orders. Contact for detailed quotation. | ||||||||||||

Raw Materials & Alloys

Crafted from premium materials for exceptional performance and durability

About Our Tungsten Carbide Crusher Blades

Tungsten carbide crusher blades represent the pinnacle of cutting technology for industrial shredding applications, offering unparalleled wear resistance and longevity. These premium blades are engineered as the ultimate solution for demanding plastic recycling operations where conventional steel blades fail prematurely. Our ShengAo tungsten carbide blades feature advanced carbide-tipped construction that delivers exceptional cutting performance, maintaining razor-sharp edges through extended production runs in the most challenging recycling environments.

Premium Material & Construction

Our crusher blades utilize industrial-grade tungsten carbide cutting edges bonded to premium tool steel bodies through advanced brazing technology. Tungsten carbide offers exceptional hardness (typically 85-92 HRA) and wear resistance that significantly outperforms even the best tool steels. Each blade features a precision-engineered carbide cutting edge that maintains sharpness 8-10 times longer than conventional steel blades. The steel body provides necessary toughness and impact resistance, while the carbide edge delivers unparalleled abrasion resistance. This hybrid construction ensures optimal performance in demanding applications, with every aspect of design, knife edge geometry, and thickness fully customizable according to your specific requirements.

Key Features & Operational Benefits

Tungsten carbide blades deliver transformative operational advantages for industrial recycling operations. The exceptional wear resistance dramatically extends service life, with blades lasting 8-10 times longer than premium steel blades in abrasive applications. This translates to significantly reduced downtime for blade changes and maintenance, maximizing equipment uptime. The blades maintain consistent cutting performance throughout their extended lifespan, ensuring uniform particle size and optimal material flow. With a comprehensive 6-month warranty, these blades offer superior protection for your investment. The fast 10-day lead time for orders up to 500 sets ensures minimal disruption to your operations. These premium blades represent the ultimate solution for operations processing highly abrasive materials or requiring maximum blade longevity.

Application Industries & Materials

These advanced tungsten carbide crusher blades excel in the most demanding recycling applications across multiple industries. They are particularly effective for: Highly Abrasive Plastics (glass-filled materials, mineral-filled compounds, reinforced plastics), Plastic Film Recycling (agricultural film, stretch film, packaging films), PET Bottle Recycling (including contaminated streams), Engineering Plastics (PEEK, PPS, PBT with high filler content), Rubber Recycling (tire rubber, industrial rubber), and Mixed Waste Streams with significant contamination. Key industries served include plastic recycling facilities, manufacturing plants, machinery repair shops, retail operations with recycling systems, and specialized material recovery facilities (MRFs). These blades are ideal for operations where blade replacement costs and downtime are critical concerns.

Customization & Quality Assurance

We specialize in providing fully customized tungsten carbide blade solutions engineered precisely for your equipment and material requirements. Every design aspect can be tailored, including overall blade design, knife edge geometry, thickness, and specific carbide grade selection based on your application. Our commitment to quality is demonstrated through video outgoing-inspection provided with every order, offering visual verification of blade quality and specifications. While machinery test reports are not available for this product line, our advanced manufacturing processes ensure consistent premium quality. We back our products with a 6-month warranty covering the tungsten carbide core component. Standard lead times are exceptionally fast: 10 days for orders of 1-500 sets, with custom scheduling for larger volumes (>500 sets). Customization options including logos, packaging, and graphics are available for orders of 100+ sets.

Top 5 Tungsten Carbide Crusher Blade Manufacturers

Selecting the right manufacturer for tungsten carbide crusher blades is crucial for achieving maximum blade life, minimizing downtime, and ensuring cost-effective operation in abrasive recycling applications. These brands are recognized for their advanced materials expertise, precision engineering, and proven performance in demanding industrial environments.

ShengAo

A premier manufacturer specializing in industrial-grade tungsten carbide crusher blades for demanding plastic recycling applications. Their advanced carbide-tipped blades offer exceptional wear resistance and longevity, lasting 8-10 times longer than premium steel blades in abrasive applications. Key advantages include comprehensive full customization of all design aspects, video outgoing-inspection for quality verification, a 6-month warranty on core components, and remarkably fast 10-day lead times for orders up to 500 sets. Recognized for providing premium blade solutions that dramatically reduce downtime and operating costs in industrial plastic recycling and waste processing operations worldwide.

Kennametal

A global leader in advanced materials and cutting solutions, Kennametal manufactures premium tungsten carbide blades and cutting tools for industrial applications. Their expertise in carbide technology and metallurgical engineering makes them a top choice for highly demanding shredding applications requiring maximum wear resistance.

Sandvik

A Swedish engineering group specializing in advanced materials technology, Sandvik produces high-performance tungsten carbide cutting tools and blades for industrial applications. Their carbide solutions are known for innovative design, consistent quality, and exceptional performance in abrasive environments.

Iscar

An Israeli multinational company specializing in precision carbide metalworking tools and cutting solutions. Iscar manufactures high-quality tungsten carbide blades and cutting inserts known for their innovative geometries and reliable performance in demanding industrial applications.

Mitsubishi Materials

A Japanese multinational corporation with extensive expertise in advanced materials, including tungsten carbide cutting tools and industrial blades. Mitsubishi Materials produces premium carbide solutions known for exceptional quality, consistency, and performance in demanding applications.

Frequently Asked Questions (FAQs)

Find expert answers to common questions about ShengAo Tungsten Carbide Crusher Blades for industrial plastic recycling and shredding applications requiring maximum wear resistance.