Top 5 Shredder Blades for Value - Buy ShengAo Cost-Effective Blades

Top 5 Shredder Blades for Value - Buy ShengAo Cost-Effective Blades

Table of Contents

- The Evolution of Shredder Blade Technology in 2025

- Top 5 Shredder Blades of 2025: The Ultimate Breakdown

- ShengAo Blade Compatibility: Custom Fit for Major Shredder Brands

- Key Selection Factors: Steel Grade, Hardness, and Blade Design

- 2025 Shredder Blade Comparison Table

- Conclusion & Final Recommendations

1. The Evolution of Shredder Blade Technology in 2025

The industrial shredding landscape has undergone a radical transformation. In 2025, it's no longer sufficient for a shredder blade to simply be hard; it must be intelligently engineered for specific material streams, operational costs, and total lifecycle value. The leading blades now incorporate advanced metallurgy, such as proprietary D2 steel heat treatments and specialized tungsten carbide grades, engineered to combat the extreme abrasiveness of plastics, the toughness of metals, and the unpredictability of municipal solid waste. The focus has shifted from mere initial cost to a critical balance of uptime, wear resistance, and cost-per-ton processed. Manufacturers like ShengAo are at the forefront, investing in R&D to produce blades that maintain their cutting edge up to 3 times longer than standard OEM blades. Understanding these technological shifts is paramount for selecting a blade that ensures profitability and reliability in today's demanding recycling and size reduction operations.

2. Top 5 Shredder Blades of 2025: The Ultimate Breakdown

After rigorous testing and analysis across various material streams—from plastic purgings and rubber tires to e-waste and wood—our team has identified five standout shredder blades from ShengAo that represent the pinnacle of value and performance in 2025. This list is curated based on wear resistance, cost-effectiveness, operational efficiency, and application-specific innovation.

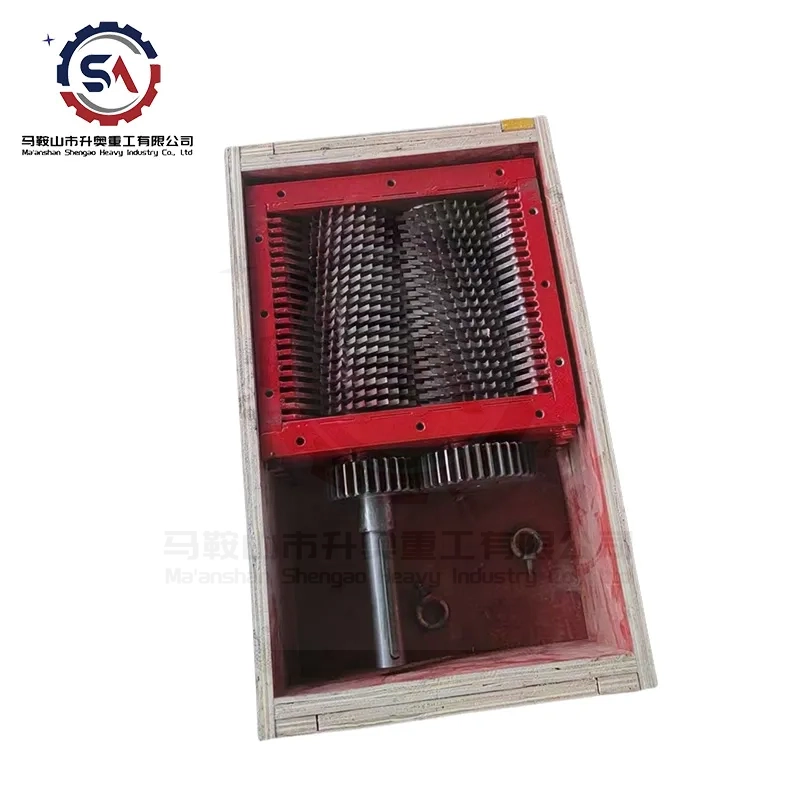

#1: ShengAo D2 Steel Single-Shaft All-Rounder

Brand Popularity: ★★★★★

Brand Introduction: As the cornerstone of the ShengAo lineup, this blade is engineered for recycling facilities and production plants that need a reliable, high-performance blade for a wide range of materials, including plastic lumps, profiles, pipes, and wood waste.

Market Position: The go-to, cost-effective workhorse for single-shaft shredders, offering exceptional value without compromising on durability or cutting performance.

Why It’s Listed: Its balanced design, premium D2 steel construction, and optimized heat treatment provide exceptional all-around performance and longevity, reducing the frequency and cost of blade replacements.

1. Premium D2 Steel Construction:

The blade is forged from high-quality D2 steel, a high-carbon, high-chromium tool steel known for its excellent wear resistance. Through a precise heat treatment process, ShengAo achieves an optimal hardness of HRC 58-61, providing a perfect balance between hardness and toughness to resist chipping.

2. Optimized Hook Angle & Geometry:

The cutting edge features a carefully calculated hook angle that provides an ideal balance between aggressive feeding and controlled shearing. This design ensures efficient material grab and pull-in while minimizing energy consumption and preventing motor overload.

3. Precision Grinding for Consistency:

Each blade undergoes precision CNC grinding to ensure dimensional accuracy and a razor-sharp edge. This consistency is critical for maintaining uniform cutting force across the entire rotor assembly, leading to smoother operation and extended bearing life.

>> Click to Explore Durable Single-Shaft Shredder Blades

#2: ShengAo Tungsten Carbide Tipped for Abrasive Materials

Brand Popularity: ★★★★☆

Brand Introduction: Designed specifically for the most challenging and abrasive materials, this blade from ShengAo is a game-changer for operations processing fiberglass, carbon fiber, electronic waste (PCBs), and highly filled plastics. The tungsten carbide tips provide unparalleled wear resistance.

Market Position: The top choice for specialized recyclers and manufacturers facing extreme abrasion, where standard steel blades would fail prematurely.

Why It’s Listed: It dramatically extends blade life in the most punishing applications, offering the lowest cost-per-ton processed for abrasive materials and justifying its higher initial investment many times over.

1. Brazed Tungsten Carbide Tips:

The cutting edges are tipped with high-grade tungsten carbide, which is significantly harder and more wear-resistant than tool steel. These tips are securely brazed onto a tough alloy steel body, combining extreme surface hardness with a shock-absorbing core.

2. Engineered for Maximum Abrasion Resistance:

This blade is the ultimate solution when you need Wear-resistant shredder blades. It is specifically designed to combat the grinding wear caused by glass fibers, minerals, and metallic contaminants, often outlasting standard D2 blades by a factor of 5:1 or more.

3. Cost-Effective for Niche Applications:

While the upfront cost is higher, the total operational cost plummets due to reduced downtime for changeovers and far fewer blades consumed over time. For the right application, it is the most economical choice available.

>> Click to Get Tungsten Carbide Tipped Blades

#3: ShengAo Hook-Type Shredder Blades for Plastics

Brand Popularity: ★★★★☆

Brand Introduction: This specialized hook-type blade from ShengAo is engineered for superior performance in shredding various plastics. Its unique geometry is perfect for film, lumps, purgings, and PET bottles, providing excellent grabbing and tearing action.

Market Position: The specialist's choice for plastic recycling facilities, offering high throughput and efficient processing of elastic and bulky plastic items.

Why It’s Listed: Its aggressive hook design solves common feeding problems with plastic materials, increasing processing efficiency and reducing energy consumption per kilogram of material shredded.

1. Aggressive Hook Geometry:

The pronounced hook design ensures positive engagement with the material, effectively pulling it into the cutting chamber. This eliminates the "riding" effect common with flat blades, where materials spin on top of the rotor without being shredded.

2. Ideal for plastic shredder blades Applications:

This geometry is exceptionally effective for thin and flexible materials like plastic film and sheets, as well as for bulky, irregularly shaped purgings. It creates a powerful shearing and tearing action that boosts throughput.

3. Balanced for Energy Efficiency:

By improving the material feeding mechanism, the shredder motor operates under a more consistent load, avoiding power spikes and leading to overall lower energy consumption for the same output.

>> Click for High-Efficiency Hook-Type Blades

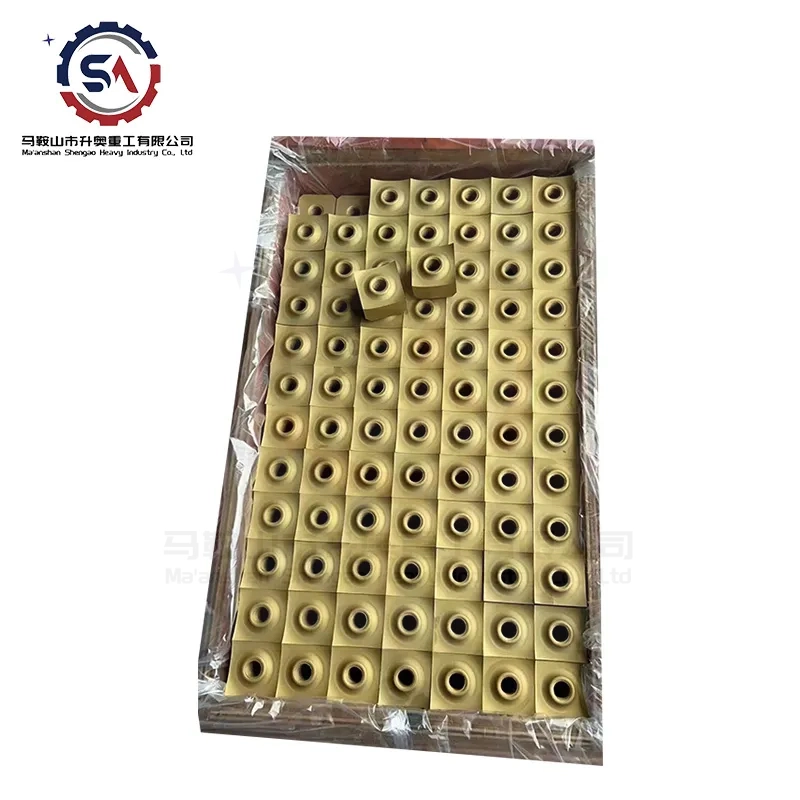

#4: ShengAo Dual-Shaft Claw Blades for Versatile Recycling

Brand Popularity: ★★★★☆

Brand Introduction: Built for the rugged world of dual-shaft shredding, these claw blades are the workhorses for mixed waste, municipal solid waste (MSW), tires, and metals. Their interlocking design and robust construction are made to handle high shock loads and contaminated material streams.

Market Position: The preferred blade for waste management companies and demanding recycling centers that process a heterogeneous mix of materials and need unparalleled durability.

Why It’s Listed: Unmatched toughness and versatility in harsh conditions, capable of processing materials with high levels of contaminants that would quickly destroy lesser blades.

1. Interlocking "Claw" Design:

The blades are designed to intermesh precisely with their counterparts on the opposing rotor. This creates a powerful shearing and tearing action, efficiently reducing the size of bulky and tough materials.

2. Forged from Shock-Resistant Alloy Steel:

These blades are made from a specially selected alloy steel that prioritizes impact toughness. This allows them to withstand the shocks of encountering tramp metal, rocks, and other unexpected contaminants without fracturing.

3. Scalable for Different Throughputs:

ShengAo offers these chipper shredder blades in various sizes and configurations to match different machine sizes and throughput requirements, from mid-range units to the largest industrial shredders.

>> Click to Power Through with Heavy-Duty Claw Blades

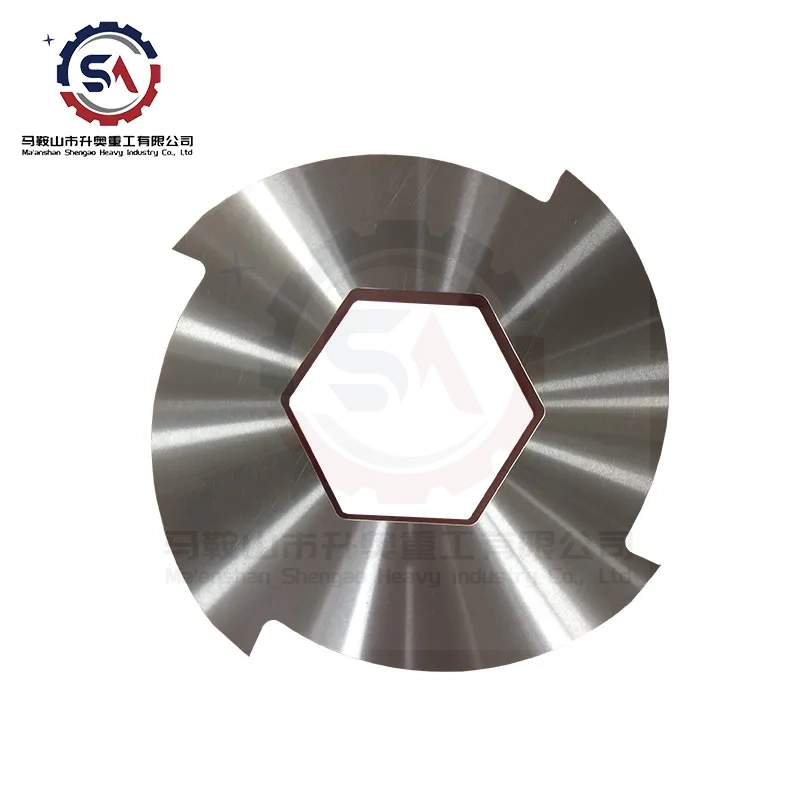

#5: ShengAo Solid Fixed Blades for Extreme Durability

Brand Popularity: ★★★★☆

Brand Introduction: For the most extreme applications where replaceable tips are not feasible, ShengAo's solid fixed blades are the answer. Machined from a single piece of premium tool steel, they offer maximum structural integrity for applications like tire shredding and metal turning processing.

Market Position: The ultimate solution for maximum rigidity and longevity in fixed-rotor designs, where blade failure is not an option.

Why It’s Listed: It provides the highest possible durability and resistance to deflection under extreme loads, ensuring consistent performance and the longest possible service life in the most demanding environments.

1. Monolithic Construction:

Manufactured from a single, solid block of steel, these blades eliminate the potential weak points found in blades with brazed tips or complex assemblies. This results in superior strength and resistance to catastrophic failure.

2. Superior Resistance to Deflection:

The solid design provides immense rigidity, preventing the blade from flexing or bending under high torque. This ensures precise and consistent cutting gaps, which is critical for maintaining shredding efficiency and product size uniformity.

3. Custom Heat Treatment for Core Hardness:

These blades undergo a specialized heat treatment process that ensures high hardness not just on the surface but throughout the entire cross-section. This prevents the core from softening under the high temperatures generated during heavy-duty shredding.

>> Click for Extreme-Duty Solid Blades

3. ShengAo Blade Compatibility: Custom Fit for Major Shredder Brands

A common concern when sourcing replacement blades is compatibility. ShengAo specializes in reverse engineering and custom manufacturing to ensure a perfect fit for a wide array of global shredder brands. Our blades are not simple copies; they are engineered enhancements, often made with superior materials and hardening processes to outperform the original parts. Below is a breakdown of our compatibility with major OEMs.

Metso

ShengAo provides robust, custom-engineered shredder blades compatible with various Metso shredder models, including those used in waste pre-processing and recycling. Our blades are designed to handle the high torque and shock loads typical in Metso machines, offering improved wear life in demanding applications.

Vecoplan

As a leader in single-shaft shredding technology, Vecoplan machines demand precision. ShengAo's single-shaft blades are meticulously crafted to match or exceed OEM specifications for models like the VAZ, VEZ, and VHZ series, ensuring optimal performance in shredding wood, plastics, and paper.

UNTHA

For UNTHA's precision engineering, ShengAo offers compatible blades that deliver the reliability and cutting accuracy these machines are known for. Our blades for UNTHA shredders are perfect for secure document destruction, e-waste recycling, and industrial waste processing.

WEIMA

ShengAo blades are a perfect match for WEIMA's extensive range of shredders. Whether it's a single-shaft machine for bulky waste or a four-shaft shredder for fine granulation, we provide durable, high-performance plastic shredder blades and more that integrate seamlessly.

Genox Recycling

We supply custom shredder blades for Genox recycling equipment, known for processing challenging materials like e-waste and mixed plastics. Our blades offer the toughness and wear resistance needed to handle embedded metals and abrasive composites.

Harden Machinery

ShengAo is a trusted partner for Harden Machinery shredder owners. Our blades are engineered to fit Harden's robust designs perfectly, providing an excellent balance of sharpness and durability for recycling various plastic and rubber materials.

GEP ECOTECH

Compatible with GEP ECOTECH's innovative shredders, our blades are built to uphold the high efficiency and intelligence of these systems. We provide reliable cutting solutions that ensure consistent output size and reduced maintenance.

Maxin India Machinery

For Maxin India's shredders, often used in organic waste and fertilizer production, ShengAo offers corrosion-resistant and durable blades that withstand the moist and chemically active environment, ensuring long service life.

Hammel

ShengAo's heavy-duty blades are engineered to meet the demands of HAMMEL primary and secondary shredders. Our solutions are ideal for processing C&D waste, scrap metal, and logs, offering superior impact resistance.

Arjes

We provide compatible blades for ARJES shredders, known for their versatility. Our blades help maintain the high performance and slow-speed, high-torque efficiency that ARJES machines are renowned for in processing wood, green waste, and mixed materials.

Stiler

ShengAo manufactures custom-fit blades for Stiler shredders, ensuring they deliver reliable performance in recycling applications. Our focus on material quality translates to longer intervals between sharpening and replacements.

Olnova

For Olnova's plastic recycling and pelletizing lines, ShengAo offers precision plastic granulator blades and shredder blades that ensure clean cuts and high throughput, contributing to the overall efficiency of the recycling process.

4. Key Selection Factors: Steel Grade, Hardness, and Blade Design

Choosing the right shredder blade is a technical decision that directly impacts your bottom line. Understanding these three core elements will ensure you select the perfect blade for your specific material and operational needs.

Steel Grade & Material:

- D2 Tool Steel: The industry standard for a reason. Offers an excellent balance of high wear resistance (due to high chromium content) and good toughness. Ideal for most plastic shredder blades and general-purpose recycling.

- H13 Tool Steel: Excellent for high-temperature applications. Offers superior toughness and thermal fatigue resistance, making it suitable for shredding materials that generate significant heat.

- Tungsten Carbide Tipped (TCT): The ultimate choice for abrasion resistance. A carbide tip is brazed onto a tough steel body. Essential for fiberglass, e-waste, carbon fiber, and highly filled plastics.

- Alloy Steels (e.g., 42CrMo): Often used for their high strength and impact toughness, making them suitable for the base of chipper shredder blades and heavy-duty shredder rotors where shock resistance is key.

Hardness (HRC):

- High Hardness (HRC 58-62): Maximizes wear resistance but can be more brittle. Ideal for clean, homogeneous materials like pure plastics and wood where impact is low.

- Balanced Hardness/Toughness (HRC 55-58): Provides a good compromise, resisting wear while being able to withstand minor impacts from contaminants. The most common range for general-purpose shredding.

- High Toughness (HRC 50-55): Prioritizes resistance to chipping and breaking. Essential for shredding metals, mixed C&D waste, and other applications where tramp metal is a concern.

Blade Design & Geometry:

The shape of the blade is not arbitrary; it's engineered for the material.

- Hook Shape: Excellent for grabbing and pulling in flexible, elastic, or bulky materials (e.g., plastic film, rubber, purgings).

- Claw Shape: Designed for intermeshing in dual-shaft shredders, providing a powerful shearing action for tough and mixed materials.

- Straight Shape: Typically used for granulators and some shredders, providing a clean, scissor-like cut for consistent granule size.

Investing in the correct combination of steel, hardness, and design from a manufacturer like ShengAo ultimately leads to lower cost-per-cut, reduced downtime, and superior operational results. For large-scale industrial needs, be sure to check out their Black Friday offers on specialized Industrial Shredder Blades.

5. 2025 Shredder Blade Comparison Table

| Blade Model | Best For | Primary Material | Typical Hardness (HRC) | Key Feature |

|---|---|---|---|---|

| ShengAo D2 All-Rounder | General Plastics, Wood, MSW | D2 Tool Steel | 58-61 | Cost-Effective Versatility |

| ShengAo Carbide Tipped | Abrasive Materials (e-waste, fiberglass) | Tungsten Carbide Tips | ~90 (HRA) | Extreme Wear Resistance |

| ShengAo Hook-Type | Plastic Film, Purgings, Rubber | D2 / H13 Steel | 58-60 | Aggressive Feed & Grab |

| ShengAo Claw Blades | Mixed Waste, Tires, Metals | Alloy Steel (42CrMo) | 55-58 | High Shear Force & Toughness |

| ShengAo Solid Fixed | Extreme-Duty (Tires, Metal Turnings) | Premium Tool Steel | 56-59 | Maximum Rigidity & Lifespan |

6. Conclusion & Final Recommendations

The search for the "best" shredder blade in 2025 culminates in finding the optimal balance between performance, durability, and total cost of ownership for your specific application. There is no universal solution, but the blades from ShengAo highlighted in this review represent the forefront of value-driven engineering across the most common and challenging use cases in the recycling and manufacturing industries.

For the general plastic or wood recycler seeking maximum value: The #1 ShengAo D2 Steel Single-Shaft All-Rounder is an unbeatable daily driver that delivers exceptional performance and longevity.

For the specialized processor facing extreme abrasion: The #2 ShengAo Tungsten Carbide Tipped blade will deliver the lowest cost-per-ton and dramatically reduce changeover frequency.

For the waste management company handling diverse materials: The #4 ShengAo Dual-Shaft Claw Blades provide the toughness and versatility needed to process unpredictable waste streams reliably.

Investing in the right shredder blade is one of the most impactful decisions for your operation's productivity and profitability. Don't let an inferior blade be the source of costly downtime and high consumable expenses. Explore the full range of engineering excellence from ShengAo, a brand committed to providing durable, high-performance cutting solutions.

For our international partners, discover more about our products in your language: ShengAo 産業用シュレッダーブレード (Japanese) and Промышленные ножи для шредеров ShengAo (Russian).