Top 3 Reasons to Choose ShengAo Shredder Blades for Your Recycling Business

Top 3 Reasons to Choose ShengAo Shredder Blades for Your Recycling Business

Table of Contents

- Introduction: The Critical Role of High-Performance Shredder Blades

- Top 3 Reasons to Choose ShengAo Shredder Blades

- Advanced Blade Technology: Materials and Manufacturing Excellence

- Optimized Performance Across Recycling Applications

- Universal Compatibility: ShengAo Blades for Your Shredder Brand

- Conclusion: Invest in Performance, Choose ShengAo

Introduction: The Critical Role of High-Performance Shredder Blades

In the competitive world of recycling operations, efficiency and reliability are paramount. At the heart of every successful recycling business lies a critical component that often determines overall productivity: the shredder blade system. These essential components face constant punishment from abrasive materials, impact forces, and shear stress in processing everything from plastics and metals to electronic waste and industrial byproducts. For recycling facility managers and business owners, the choice of shredder blades directly impacts operational costs, maintenance schedules, and ultimately, profitability.

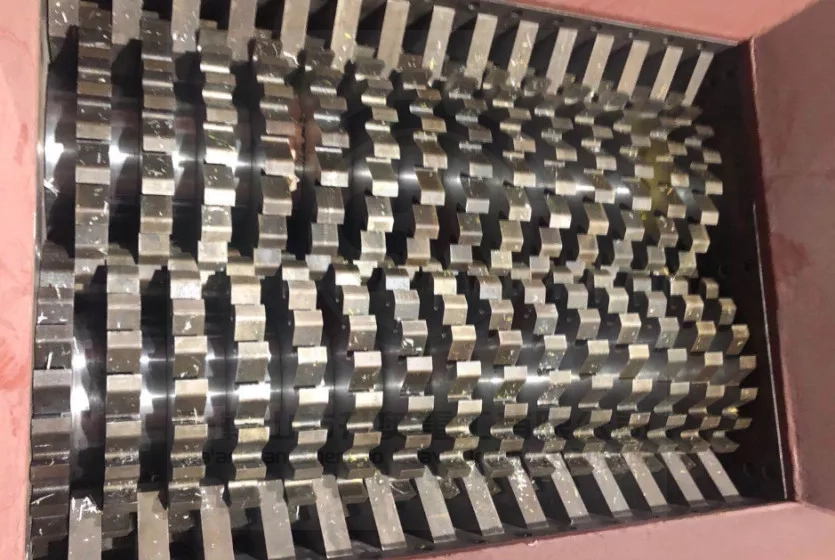

Frequent blade failure, premature dulling, or inconsistent performance can lead to devastating consequences including unplanned downtime, reduced throughput quality, and skyrocketing maintenance expenses. This is where the engineering excellence of ShengAo shredder blades creates a distinct competitive advantage. Specializing exclusively in single shaft and double shaft shredder blades, with particular expertise in single shaft applications, ShengAo has engineered a comprehensive solution that addresses the most challenging aspects of modern recycling operations.

This in-depth analysis explores the three fundamental reasons why ShengAo shredder blades outperform competitors and deliver exceptional value for recycling businesses. We'll examine how high-strength alloy steel construction, precision heat treatment processes, and innovative claw designs work synergistically to extend blade life, reduce operating costs, and maximize productivity in both metal and plastic recycling applications.

Top 3 Reasons to Choose ShengAo Shredder Blades

When evaluating shredder blades for your recycling operation, three critical factors separate premium performance from mediocre results. ShengAo has engineered its blades to excel in each of these areas, creating a comprehensive solution that delivers measurable operational benefits.

1. High-Strength Alloy Steel Construction for Maximum Durability

The foundation of any high-performance shredder blade begins with material selection. ShengAo utilizes premium high-strength alloy steels specifically formulated to withstand the extreme demands of recycling applications. Unlike standard blades that may use generic steel compositions, ShengAo blades are crafted from specialized alloys including D2, SKD-11, and Cr12MoV shredder blades, each selected for specific performance characteristics.

D2 tool steel, with its high carbon and chromium content, provides an exceptional balance of wear resistance and toughness, making it ideal for general-purpose recycling applications. SKD-11 (the Japanese JIS equivalent) offers enhanced performance with superior dimensional stability during heat treatment. For the most demanding applications, ShengAo employs specialized alloys that maintain structural integrity under extreme stress, preventing catastrophic failure and extending service intervals.

The manufacturing process begins with rigorous material verification, ensuring each steel batch meets exacting standards for composition and purity. This meticulous approach to material selection forms the first pillar of ShengAo's performance advantage, creating blades that maintain their cutting integrity through thousands of hours of operation in challenging recycling environments.

Best For: Operations processing mixed materials, including plastics, rubber, wood, and non-ferrous metals where impact resistance and overall durability are paramount.

2. Precision Heat Treatment for Superior Wear Resistance

While premium steel selection provides the foundation, it is the precision heat treatment process that unlocks the full potential of ShengAo shredder blades. Heat treatment is both a science and an art, and ShengAo has mastered this critical manufacturing step through decades of experience and technological investment.

The heat treatment process begins with carefully controlled pre-heating phases that prepare the steel microstructure for transformation. This is followed by precise austenitizing at optimal temperatures specific to each alloy composition. ShengAo utilizes advanced vacuum heat treatment furnaces that prevent surface decarburization and oxidation, preserving the integrity of the cutting edges.

The quenching process employs proprietary techniques that ensure uniform cooling throughout the blade cross-section, minimizing internal stresses that can lead to premature failure. Finally, multiple tempering cycles optimize the balance between hardness and toughness, creating blades that resist chipping while maintaining sharp cutting edges.

The result of this meticulous process is a hardened shredder blade with consistent hardness throughout the entire component, not just at the surface. This uniform hardness profile ensures that ShengAo blades maintain their performance characteristics even after multiple sharpening cycles, significantly extending total service life and reducing cost per operating hour.

Best For: Applications involving highly abrasive materials such as e-waste, engineering plastics, fiberglass, and continuous processing operations where extended wear resistance is critical to operational efficiency.

3. Innovative Claw Designs for Extended Blade Life

The third pillar of ShengAo's performance advantage lies in innovative claw geometry and cutting edge designs. Unlike one-size-fits-all approaches, ShengAo engineers specific blade profiles optimized for different material types and processing requirements. These sophisticated designs maximize cutting efficiency while minimizing power consumption and wear.

For single shaft shredders, ShengAo offers specialized hook designs that create superior material grabbing action, preventing slippage and ensuring consistent feed rates. The geometry of these hooks is calculated based on material characteristics, with more aggressive angles for tough, resilient materials and optimized profiles for brittle or flexible feedstocks.

Spiral and staggered claw configurations provide scissor-like cutting action that reduces overall force requirements while creating cleaner particle size distributions. These advanced designs particularly excel in shredder blades for plastic recycling applications where consistent flake size is critical to downstream processing efficiency.

For double shaft applications, ShengAo engineers intermeshing rotor designs that create powerful shear forces with minimal energy consumption. The precise clearance management between opposing blades ensures clean cutting action without excessive friction or heat generation. This attention to design detail results in blades that not only last longer but also operate more efficiently, reducing overall energy costs while maintaining throughput quality.

Best For: Specialized applications requiring specific particle size distributions, operations processing challenging materials with varying physical properties, and businesses seeking to optimize energy efficiency alongside blade longevity.

Advanced Blade Technology: Materials and Manufacturing Excellence

Beyond the three core advantages, ShengAo integrates multiple advanced technologies throughout the manufacturing process to ensure consistent quality and performance. From raw material to finished product, every ShengAo blade undergoes rigorous quality control and precision engineering.

CNC machining centers with sub-micron precision ensure dimensional accuracy that exceeds industry standards. This manufacturing precision guarantees perfect fitment and optimal performance in your specific shredder model. Advanced grinding technology creates razor-sharp cutting edges with exceptional consistency, while specialized edge preparation techniques enhance durability and reduce break-in periods.

For particularly challenging applications, ShengAo offers tungsten carbide-tipped blades that provide exceptional wear resistance in the most abrasive environments. These specialized blades feature carbide inserts strategically positioned at high-wear areas, combining the extreme hardness of tungsten carbide with the toughness of premium alloy steel. This hybrid approach delivers performance characteristics unmatched by conventional blades, particularly in metal scrap and electronic waste processing.

ShengAo's technical team works closely with customers to develop Custom shredder blades OEM solutions for unique applications. Whether modifying standard designs or creating completely new configurations, this collaborative approach ensures optimal performance for specific material streams and operational requirements.

Optimized Performance Across Recycling Applications

The true measure of shredder blade performance lies in real-world application results. ShengAo blades deliver demonstrated advantages across the spectrum of recycling operations, with specific formulations optimized for different material categories.

For metal scrap shredder blades applications, ShengAo employs specialized alloys and heat treatment protocols that withstand the extreme impact forces encountered when processing ferrous and non-ferrous metals. Enhanced toughness characteristics prevent chipping and catastrophic failure, while maintained hardness ensures extended wear resistance against abrasive metal surfaces.

In plastic recycling, ShengAo has developed blade formulations that resist the unique challenges posed by various polymer types. From the abrasive nature of reinforced plastics to the gumming tendencies of certain thermoplastics, specific edge geometries and surface treatments address these material-specific issues. The result is consistent particle size distribution and reduced contamination in the recycled output.

For e-waste shredder blades, ShengAo offers specialized solutions that handle the mixed material composition typical of electronic scrap. These blades maintain sharp cutting edges while processing combinations of plastics, metals, and circuit boards, with enhanced corrosion resistance to withstand potentially reactive material combinations.

Wood processing applications benefit from ShengAo blades with optimized clearance angles that prevent material wrapping while maintaining efficient cutting action. Specialized surface treatments reduce friction and resin buildup, extending sharpness retention in continuous operation environments.

| Application | Recommended Blade Type | Key Performance Features | Expected Service Life Improvement |

|---|---|---|---|

| Plastic Recycling | D2/SKD-11 with specialized coating | Reduced material sticking, consistent flake size | 30-50% longer than standard blades |

| Metal Scrap | Enhanced toughness alloys | Chip resistance, impact durability | 40-60% longer than standard blades |

| E-Waste Processing | Corrosion-resistant formulations | Mixed material capability, wear resistance | 50-70% longer than standard blades |

| Wood Waste | Anti-wrapping designs | Reduced friction, resin resistance | 35-55% longer than standard blades |

| Tire Shredding | Tungsten carbide enhanced | Steel cord cutting capability, extreme wear resistance | 100-200% longer than standard blades |

Universal Compatibility: ShengAo Blades for Your Shredder Brand

A significant advantage of choosing ShengAo is our extensive capability for customization and reverse engineering. We pride ourselves on producing high-quality shredder blades for single shaft machine and double shaft configurations that are fully compatible with a wide array of international shredder brands. Our engineering team can custom-manufacture blades to perfectly match your machine's rotor and chamber specifications, ensuring optimal performance and fit.

ShengAo blades are precision-engineered for compatibility with the following major shredder brands:

- Metso: Our custom-engineered blades provide reliable performance for Metso's robust shredders used in waste recycling and mining applications. The precise dimensional accuracy ensures perfect fitment and optimal cutting clearance.

- Vecoplan: We offer precision-matched blades for Vecoplan's single shaft shredders, ensuring high throughput in wood, plastic, and waste processing. Specialized geometries match Vecoplan's advanced feeding systems.

- UNTHA: ShengAo blades are designed to meet the exacting standards of UNTHA shredders, delivering durability for tough industrial and commercial waste applications. Enhanced toughness formulations handle UNTHA's high-torque requirements.

- WEIMA: Compatible blades for WEIMA's extensive range of single shaft shredders, perfect for size reduction in plastics, wood, and paper. Optimized for WEIMA's specific rotor designs and cutting principles.

- Genox Recycling: We provide high-wear-resistant blades that match Genox machines, ideal for challenging e-waste and plastic recycling applications. Special corrosion-resistant treatments for Genox's demanding environments.

- Harden Machinery: Custom-fit blades for Harden's shredders, supporting efficient recycling of plastics, tires, and other solid wastes. Engineered for Harden's specific mechanical configurations.

- GEP ECOTECH: Our blades are compatible with GEP ECOTECH shredders, offering solid performance in municipal solid waste and industrial recycling. Enhanced designs for GEP's high-volume processing requirements.

- Maxin India Machinery: We supply durable blades tailored for Maxin shredders, effective for organic waste, plastic, and fertilizer production lines. Climate-adapted formulations for varied operating conditions.

- Hammel: ShengAo manufactures robust blades compatible with Hammel's primary and secondary shredders, built for processing scrap metal, wood, and waste. Heavy-duty construction for Hammel's powerful systems.

- Arjes: Our custom blades fit Arjes shredders, providing the strength needed for slow-speed, high-torque processing of mixed materials. Optimized for Arjes' unique cutting action.

- Stiler: We offer compatible blades for Stiler shredders, ensuring efficient performance in various recycling and waste management setups. Precision engineering for Stiler's specific dimensional requirements.

- Olnova: ShengAo provides reliable blade solutions for Olnova machines, suitable for a variety of recycling and size reduction tasks. Comprehensive compatibility with Olnova's range of shredder models.

If your machine brand is not listed, please contact us. Our technical team can create a perfect OEM shredder blades solution for virtually any shredder model, regardless of manufacturer or age.

Conclusion: Invest in Performance, Choose ShengAo

In the demanding world of recycling operations, the choice of shredder blades represents one of the most significant decisions affecting operational efficiency and profitability. The three core advantages of ShengAo shredder blades—high-strength alloy steel construction, precision heat treatment, and innovative claw designs—work synergistically to deliver unparalleled performance and value.

By investing in ShengAo blades, recycling businesses benefit from extended service intervals, reduced downtime, consistent output quality, and lower operating costs. The specialized formulations for different material types ensure optimal performance across diverse applications, from plastic and metal recycling to electronic waste processing and wood size reduction.

The compatibility of ShengAo blades with major shredder brands, combined with our extensive custom engineering capabilities, makes ShengAo the ideal partner for operations of all sizes. Whether you require standard replacement blades or completely custom solutions, our technical team possesses the expertise to deliver precisely what your operation needs to maximize productivity and profitability.

and discover how our engineering excellence can benefit your specific application.Long life shredder bladesDon't let substandard blades compromise your recycling operation's potential. Experience the ShengAo difference and transform your shredding performance.