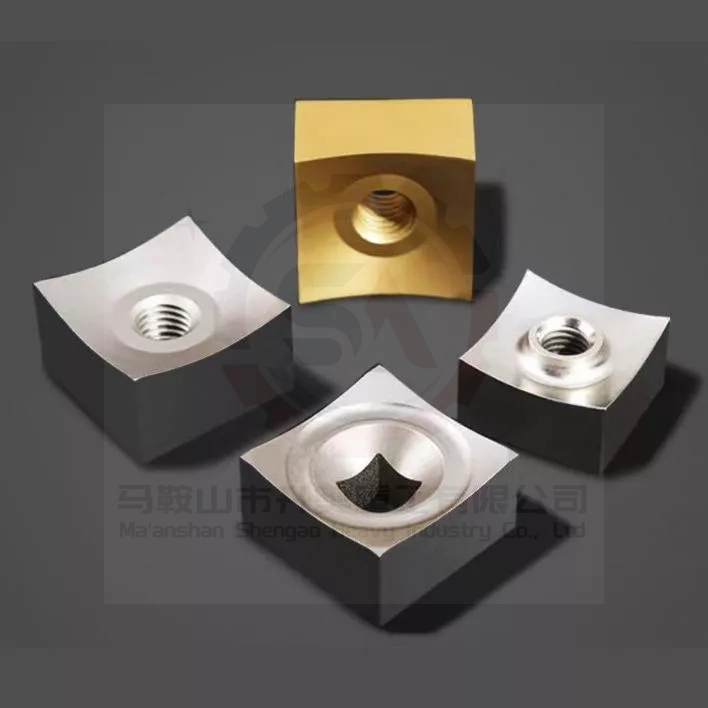

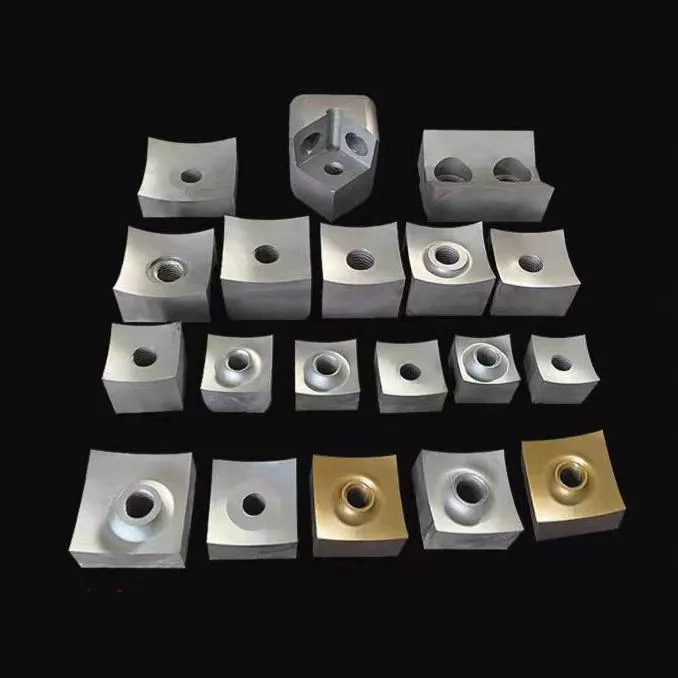

Threaded Hole Single Shaft Shredder Knife Shredder Blades For Waste Recycling Machine

Single shaft shredder knives with threaded holes for easy installation. Designed for waste recycling machines, providing secure fitting and reliable cutting for various recyclable materials.

Get instant pricing and technical specifications for your project requirements

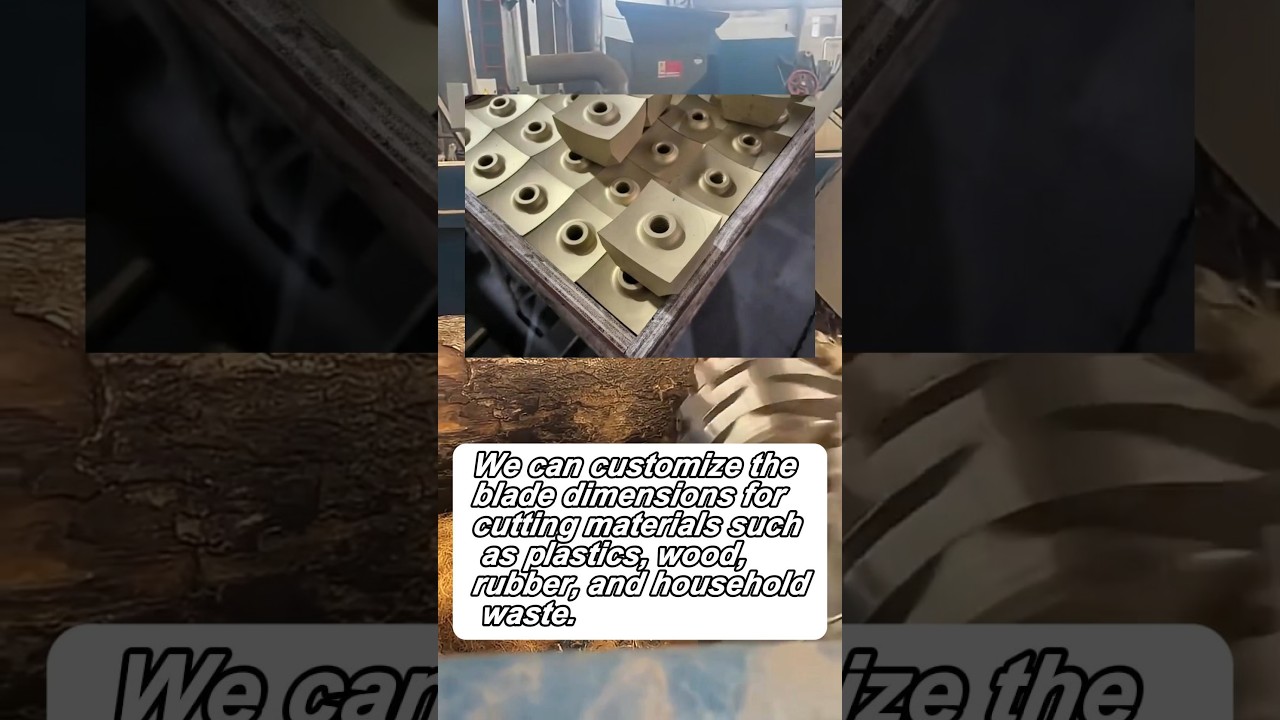

Product Video Demonstration

Product Specifications

| Shredder Blades - Threaded Hole Single Shaft Knives | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Threaded Hole Single Shaft Shredder Knife Shredder Blades For Waste Recycling Machine Single shaft shredder knives with threaded holes for easy installation. Designed for waste recycling machines, providing secure fitting and reliable cutting for various recyclable materials. | ||||||||||

| Product Specifications | Material 5WSiCr / H13H / DC53 Spare Parts Type Blade Application Plastic Recycling Industry Size Customized Size Product Name Shredder Blades Place of Origin Anhui, China Weight (KG) 15 MOQ 1 Set Key Selling Points High Safety Level Long Service Life High-Accuracy | |||||||||

| Quality Assurance | Quality Control & Documentation Video Outgoing-Inspection: Provided Machinery Test Report: Provided Warranty & Support 1.5 Warranty Period: 1.5 Year ! Product Type: Plastic Shredder Machine Blade | |||||||||

| Lead Time |

Lead time starts from order confirmation and deposit received. | |||||||||

| Customization Options | Customized Logo Add your company logo to the product or packaging. Min. order: 100 pieces Customized Packaging Tailor the packaging design to your brand requirements. Min. order: 100 pieces Graphic Customization Custom graphics or markings on the product as per request. Min. order: 100 pieces All customization options require a minimum order quantity. Contact for detailed quotes. | |||||||||

Raw Materials & Alloys

Crafted from premium materials for exceptional performance and durability

About Our Threaded Hole Single Shaft Shredder Knives

The threaded hole single shaft shredder knives are precision-engineered cutting components designed for waste recycling machines. Featuring integrated threaded mounting holes, these blades offer superior installation security and operational stability. As the core component of single shaft shredders, they efficiently reduce the size of various recyclable materials for easier handling, processing, and recycling. Engineered with high-precision manufacturing techniques, these custom-made blades deliver maximum performance, durability, and reliability in demanding waste processing applications.

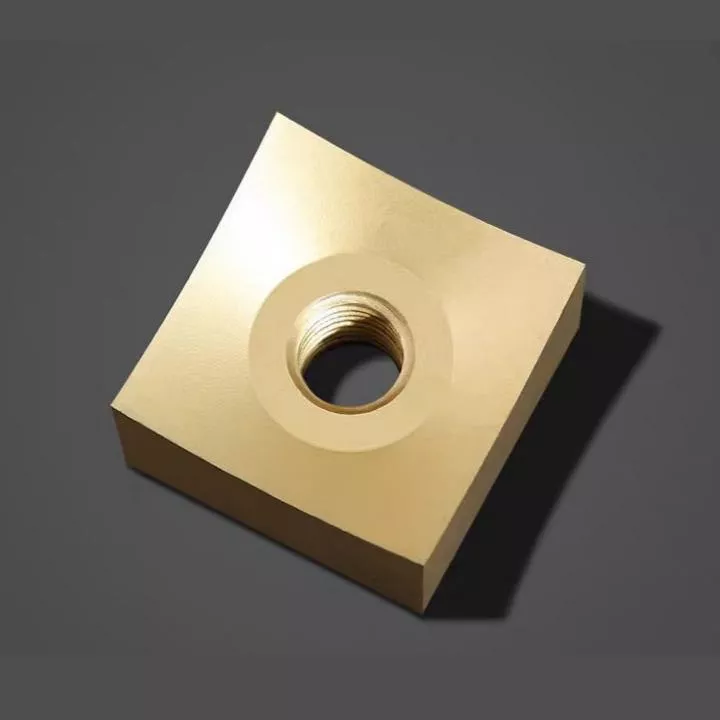

Premium Material & Construction

Our threaded hole shredder blades are manufactured from premium tool steels including 5WSiCr, H13H, and DC53, each selected for specific performance characteristics. 5WSiCr offers excellent wear resistance and toughness for general plastic recycling applications. H13H provides superior thermal fatigue resistance for high-temperature operations, while DC53 delivers exceptional hardness and impact resistance for the most challenging materials. Each blade features precision-machined threaded holes that ensure secure mounting without bolt heads protruding, creating a smooth cutting surface. The integrated thread design eliminates the need for separate fasteners, reducing installation time and preventing loose components during operation.

Key Features & Benefits

Designed with three key selling points—High Safety Level, Long Service Life, and High-Accuracy—these blades offer exceptional operational advantages. The threaded hole design provides maximum security, preventing blade dislodgement during operation and reducing the risk of catastrophic machine failure. With weights typically around 15kg, these robust blades are built for durability, significantly extending service intervals and reducing maintenance downtime. Their high-precision manufacturing ensures exact dimensional accuracy, resulting in consistent cutting performance, uniform particle size, and optimal machine efficiency. The combination of these features leads to higher throughput, lower operating costs, and improved safety in waste recycling operations.

Application Industries & Materials

These versatile threaded hole blades are specifically engineered for the plastic recycling industry and related waste processing applications. They excel in shredding various plastic materials including PET bottles, HDPE containers, PP packaging, PVC profiles, plastic films, and engineering plastic lumps. Additionally, they effectively process other recyclable materials such as rubber, textiles, paper, and cardboard. Industries that benefit include plastic recycling facilities, waste management companies, material recovery facilities (MRFs), and manufacturing plants with in-house scrap processing. These blades are ideal for single shaft shredders used in bottle-to-flake recycling, post-industrial plastic scrap reduction, and general waste size reduction operations.

Customization & Quality Assurance

We specialize in providing fully customized threaded hole shredder knife solutions to perfectly match your specific machine requirements. With a remarkably low Minimum Order Quantity (MOQ) of just 1 set, we cater to both small-scale operations and large recycling facilities. All dimensions, thread specifications, and material choices can be tailored to your needs. Our commitment to quality is demonstrated through comprehensive documentation including official machinery test reports and video outgoing-inspection for every order. Backed by an industry-leading 1.5-year warranty, the longest in the market, these blades represent an exceptional value proposition. Securely packaged to prevent damage during transit, they arrive ready for immediate installation and long-term reliable service.

Top 5 Single Shaft Shredder Blade Brands for Plastic Recycling

Selecting the right blade brand is critical for shredder efficiency and longevity in plastic recycling. These manufacturers are recognized for their material expertise, precision engineering, and proven performance in single shaft shredding applications.

ShengAo

A leading manufacturer specializing in threaded hole single shaft shredder knives for plastic recycling. Their blades are produced from premium materials (5WSiCr, H13H, DC53) and feature integrated threaded holes for superior mounting security. Known for exceptional quality control with both machinery test reports and video inspections, they offer an industry-leading 1.5-year warranty, low MOQ (1 set), and excellent lead times (31 days for up to 5000 pieces). Their focus on high safety, long service life, and high accuracy makes them a top choice for waste recycling operations.

Vecoplan

The German engineering leader offers high-quality single shaft shredder knives as original equipment for their machines. Vecoplan blades are designed for precision cutting, excellent wear resistance, and are often optimized for specific plastic materials, providing reliable performance in continuous industrial recycling applications.

WEIMA

Another German manufacturer renowned for efficient single shaft shredding technology. WEIMA produces durable knives designed for low energy consumption and easy maintenance, with various mounting systems including bolt-on and specialized designs for different plastic recycling applications.

Zerma

A specialist in size reduction technology, Zerma manufactures robust single shaft shredder knives with a focus on longevity and cost-effectiveness. Their designs often feature reversible or multi-edge configurations to maximize blade life and reduce total cost of ownership in plastic recycling operations.

Rapid Granulator

While primarily known for granulators, Rapid also produces precision knives for their single shaft shredding systems. Their blades focus on clean cutting with minimal heat generation to preserve material properties, making them suitable for high-quality plastic scrap recycling where material degradation must be minimized.

Frequently Asked Questions (FAQs)

Get expert answers to the most common questions about Threaded Hole Single Shaft Shredder Knives for plastic recycling applications.