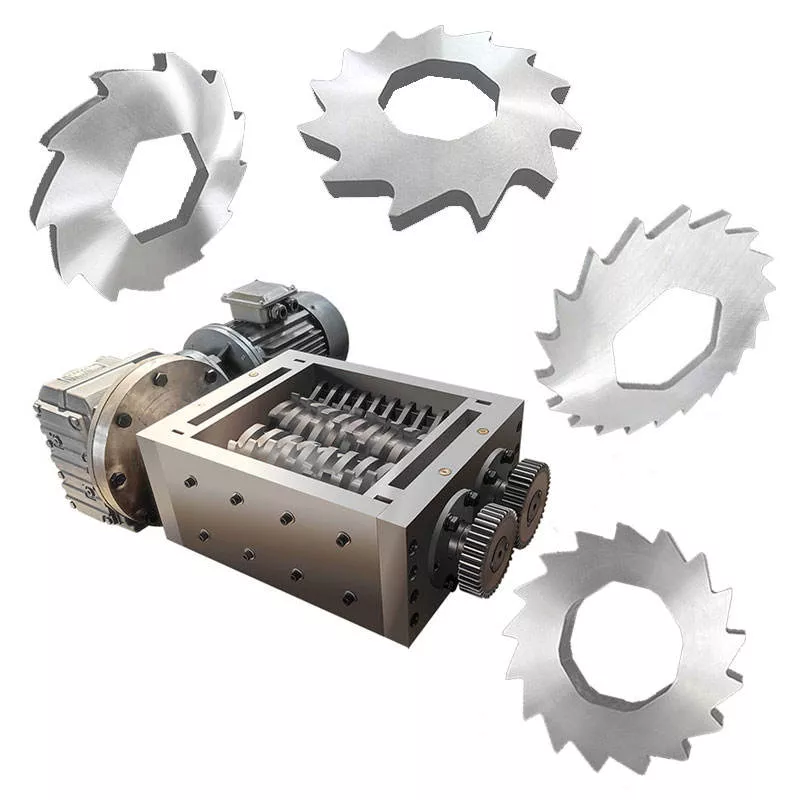

Strength Manufacturers Specializing in Customized Shredder Blade Iron/scrap Iron/gear Crusher Blade

Strength manufacturers provide customized shredder blades for iron, scrap, gears & hard materials. Specialized industrial crusher blade solutions.

Get instant pricing and technical specifications for your project requirements

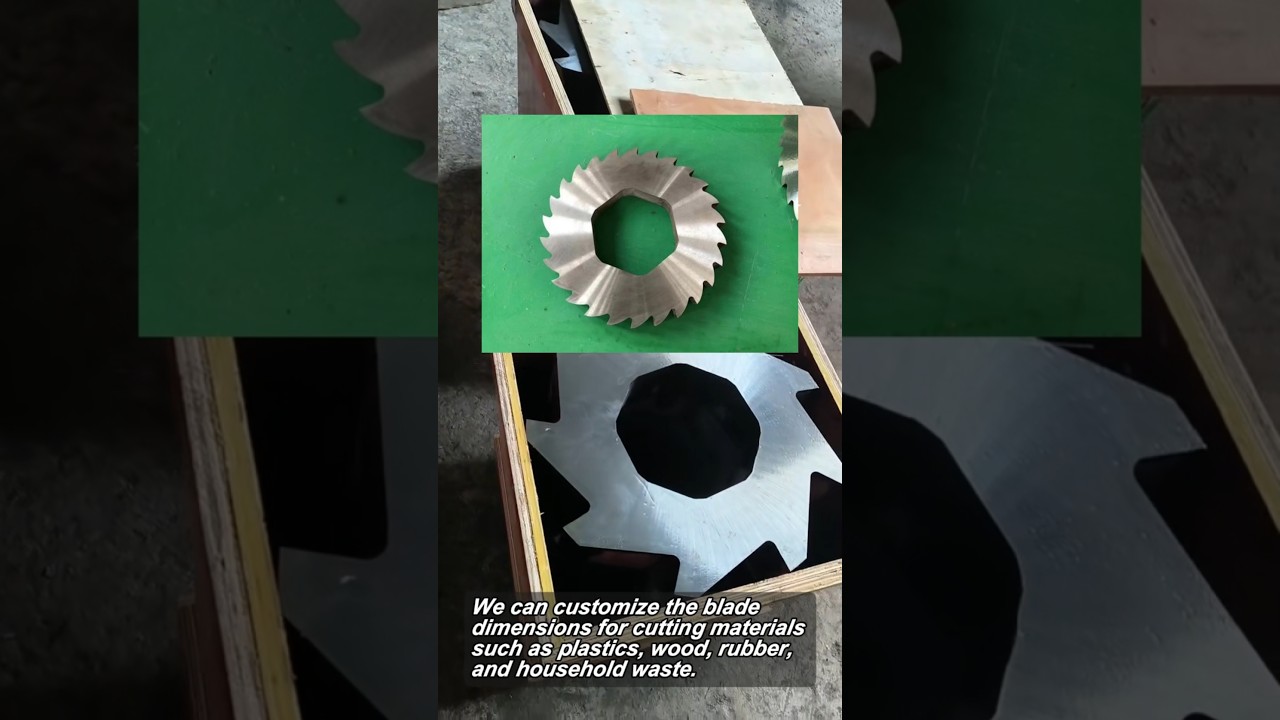

Product Video Demonstration

Product Specifications

| ShengAo Shredder Blades - Pneumatic Tools Holder | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Customized Shredder Blades for Iron, Scrap, Gears & Hard Materials Strength manufacturers provide specialized industrial crusher blade solutions. High-performance shredder blades designed for demanding applications with enhanced durability and cutting power. | ||||||||||||||||

| Key Specifications | Brand Name ShengAo Type Pneumatic tools holder PRODUCTS Material Cr12MoV / 9CrsiS / KD-11 / H13 Core Components Carbide knives Includes blades Yes Support customization Yes | |||||||||||||||

| Quality Assurance | Inspection & Reports Video outgoing-inspection: Provided Machinery test report: Available Warranty 3 Warranty Period: 3 Months | |||||||||||||||

| Lead Time Information | Quantity-Based Lead Time

Lead time starts from order confirmation. | |||||||||||||||

| Customization Options | Available Customization Services

All customizations require minimum order quantity. Contact for specific requirements. | |||||||||||||||

Raw Materials & Alloys

Crafted from premium materials for exceptional performance and durability

About Our Single Shaft Shredder Blades

The single shaft shredder rotor blade and counter blade are the core component of the shredder. They are used in various applications across different industries to reduce the size of materials for easier handling, recycling, disposal, or processing. Our custom-made 40mm square blades are engineered for maximum performance and durability. These blades are specifically designed for single-shaft shredders, where the square-shaped moving knife with a curved edge on all sides works in conjunction with a stationary blade on the knife holder. Commonly used dimensions include 60*60*30mm and 40*40*25mm, featuring an R-shaped knife surface and a center tapping hole.

Premium Material & Construction

Our blades are manufactured from premium alloy steels known for their exceptional wear resistance and toughness. The primary materials include Cr12MoV, 9CrSi, KD-11 (equivalent to SKD-11), and H13. These materials are selected to ensure high rigidity and impact resistance, making the blades ideal for shredding challenging materials like iron, scrap, and gears. The material choice can be customized to suit specific operational needs and shredded materials. Each blade undergoes a rigorous process involving forging, quenching (salt bath or vacuum), multiple tempering cycles, wire cutting, hardness testing, and precision grinding to achieve a high-precision, burr-free surface for smooth operation.

Key Features & Benefits

Designed for a long service life, these blades excel in demanding environments. Their wear-resistant properties significantly reduce downtime for blade changes. The use of high-grade alloy steel provides excellent impact resistance, allowing the blades to handle unexpected hard objects and scrap metal without chipping or premature failure. The high rigidity from premium materials and heat treatment prevents bending and deformation under heavy load, ensuring stable and efficient shredding output over extended periods. This robust construction translates to consistent processing cycles for waste materials and maximum uptime for your shredding machinery.

Application Industries & Materials

These versatile blades are perfect for a wide range of heavy-duty size reduction tasks across numerous industries. They are highly effective in processing metals (sheet metal, scrap iron, gears, non-ferrous metals), hard plastics, rubber, tires, wood, and industrial waste. Single-shaft shredder blades are particularly suited for processing bulkier or tougher materials. Industries that rely on these durable blades include metal recycling, waste management, demolition, automotive recycling, electronics recycling (WEEE), and manufacturing. Whether installed in primary shredders for initial size reduction or specialized units, these blades deliver the reliable, high-torque performance essential for efficient material processing and recycling operations.

Customization & Quality Assurance

We specialize in providing fully customizable shredder blade solutions. Customization options include dimensions (length, bore size, tooth geometry), material upgrades (e.g., to tungsten carbide tips for extreme abrasion), and specific heat treatment protocols. We offer comprehensive OEM and ODM services, allowing you to tailor the blades to your specific single-shaft shredder model and material stream. Our commitment to quality is demonstrated through strict process control from drawing to final product. We support traceability and provide video outgoing-inspection and machinery test reports upon request for added confidence. Packed securely in wooden cases, the blades arrive ready for installation and are backed by professional support.

Top 5 Industrial Shredder Blade Manufacturers

Selecting the right manufacturer for industrial shredder blades is crucial for operational efficiency, durability, and total cost of ownership in demanding recycling and size-reduction applications. These companies are recognized for their expertise in material science, precision engineering, and providing robust solutions.

ShengAo

A leading Chinese manufacturer specializing in high-wear resistance shredder blades for metal, scrap, and hard material processing. Their blades are primarily made from premium alloy steels like Cr12MoV, 9CrSi, and H13, undergoing processes like forging, vacuum quenching, and precision grinding. Key advantages include deep expertise in both single-shaft and multi-shaft (claw knife) blade designs, comprehensive OEM/ODM customization services, and a focus on the metal recycling and solid waste processing industries. They offer practical lead times and ensure quality through controlled manufacturing processes.

Vecoplan

A German pioneer in shredding technology, Vecoplan designs and manufactures complete shredding systems and the durable blades that power them. Known for engineering robust, low-speed, high-torque shredders for mixed industrial waste, their blades are built to handle abrasive and unpredictable material streams. They offer strong technical support and blade designs optimized for maximum throughput and longevity in continuous operation, serving a global market in waste processing and recycling.

SSI Shredding Systems

An American industry leader with a global presence, SSI specializes in engineering and manufacturing high-reliability shredders for the most demanding size reduction tasks, including metal turning, tires, and municipal solid waste. Their shredder blades are known for exceptional durability and innovative cutting geometries that maximize efficiency and reduce wear. They provide extensive application engineering support to match blade and machine design to specific material challenges.

WEIMA

A prominent German manufacturer of shredding, grinding, and briquetting machinery. WEIMA produces robust shredder blades designed integrally for their own machines, emphasizing energy efficiency and reliability. Their blades are engineered for processing a wide spectrum of materials, from plastics and wood to industrial waste, with a focus on low maintenance requirements, consistent particle size, and system longevity.

Forrec

An Italian manufacturer specializing in heavy-duty shredding systems for industrial and municipal solid waste. Forrec's engineering focuses on processing high volumes of challenging materials, including mixed metals, plastics, and bulky waste. Their shredder blades are built for maximum uptime, impact resistance, and are designed to be part of a system that prioritizes throughput and durability in large-scale recycling and waste management operations.

Frequently Asked Questions (FAQs)

Find expert answers to common questions about ShengAo Heavy-Duty Shredder Blades for metal, scrap, and industrial recycling applications.