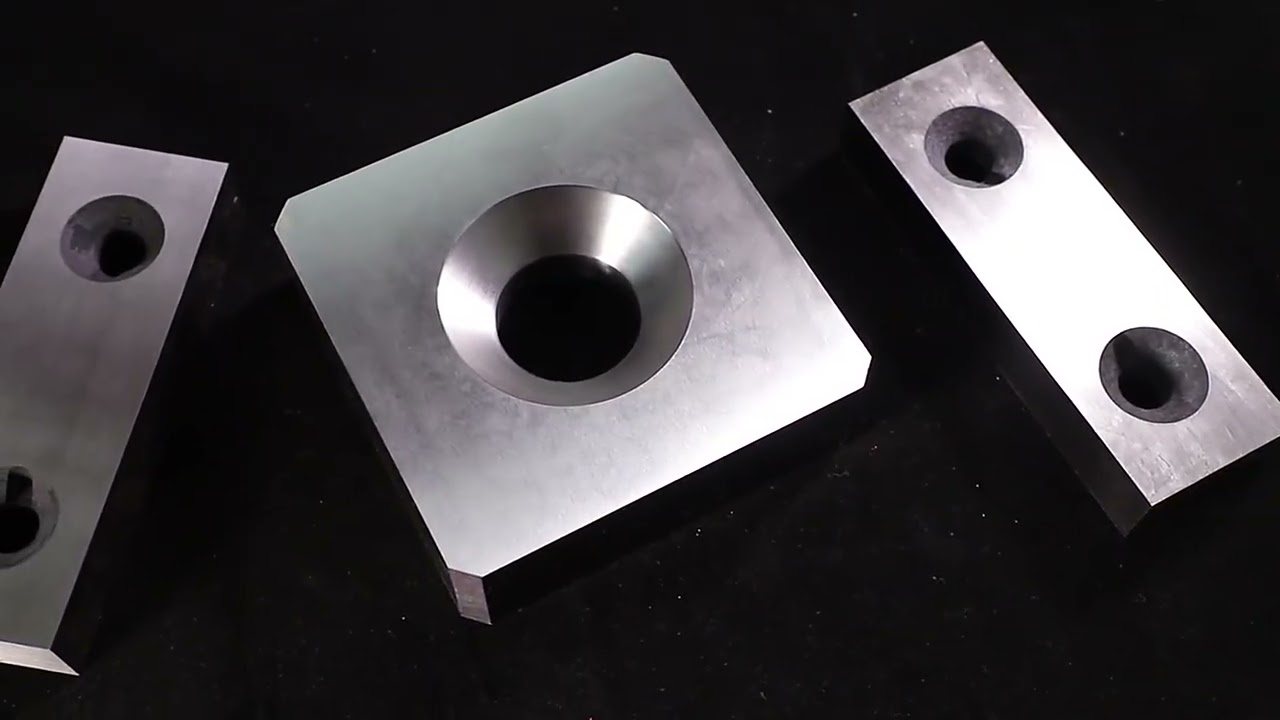

Steel Particle Machine Blade 650 Double Head Cutting Machine 750/1000 Type Random Steel Shredder Blade

Robust 650/750/1000 type double-head steel shredder blades for particle machines. Designed for random steel cutting with enhanced durability and cutting power.

Get instant pricing and technical specifications for your project requirements

Product Video Demonstration

Product Specifications

| ShengAo Steel Pellet Machine Blades - Double Head Cutting Machine Blades | |||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Steel Particle Machine Blade 650 Double Head Cutting Machine 750/1000 Type Random Steel Shredder Blade Robust 650/750/1000 type double-head steel shredder blades for particle machines. Designed for random steel cutting with enhanced durability and cutting power. | |||||||||||||||||||||||||||||||||||||||||||||||||

| Available Specifications | Material: 1211-A6 Steel

Note: All specifications available in 1211-A6 material. Custom sizes and configurations available upon request. | ||||||||||||||||||||||||||||||||||||||||||||||||

| Product Specifications | Brand Name ShengAo Type Blade Product Name Steel pellet machine blade Place of Origin Anhui, China Blade Material 1211 Steel Service Customization supported | ||||||||||||||||||||||||||||||||||||||||||||||||

| Quality Assurance | Quality Control Machinery test report: Provided Video outgoing-inspection: Provided Warranty & Core Components 3 Warranty: 3 Months 1211 Core Components: 1211 Steel Construction | ||||||||||||||||||||||||||||||||||||||||||||||||

| Delivery Information | Standard Delivery Time 7-30 days Standard Production Quantity-Based Lead Time

Lead time starts from order confirmation and deposit received | ||||||||||||||||||||||||||||||||||||||||||||||||

Raw Materials & Alloys

Crafted from premium materials for exceptional performance and durability

About Our Steel Pellet Machine Blades

The double-head cutting machine blade is the core component of steel pellet machines and random steel shredders. Specifically designed for the demanding task of reducing random steel scraps into uniform particles, these robust blades are the heart of 650, 750, and 1000-type machines. ShengAo's precision-engineered blades are built to withstand the extreme forces involved in metal shredding, ensuring your equipment operates at peak efficiency for processing steel into reusable pellets for recycling or further manufacturing.

Core Advantage: ShengAo blades are manufactured from specialized 1211-A6 steel, offering exceptional toughness for metal-on-metal impact. We provide comprehensive quality verification through machinery test reports and video outgoing-inspection, backed by a 3-month warranty. Our extensive range of standard sizes and hole configurations ensures a perfect fit for your machine.

Premium Material & Construction

Our steel pellet machine blades are exclusively crafted from 1211-A6 steel, a specialized alloy formulation chosen for its superior impact resistance and durability in the most abrasive and high-shock environments. This material is engineered to absorb the tremendous forces generated when cutting random steel scrap, preventing catastrophic failure and maintaining structural integrity.

Each blade is forged and heat-treated to achieve optimal metallurgical properties, then precision-machined to exacting dimensional tolerances. We offer a wide array of standard configurations to suit various machine models:

- Dimensions: From compact 90x65x40mm to heavy-duty 240x80x26mm and 215x120x30mm.

- Hole Configurations: Two-hole, three-hole (with wire/countersunk), four-hole, and threaded options for secure mounting.

- Thickness: Ranging from 26mm to 50mm, providing the necessary mass for momentum and cutting power.

This meticulous construction ensures each blade delivers consistent, reliable performance, batch after batch, under the extreme conditions of steel scrap processing.

Key Features & Benefits

ShengAo double-head steel shredder blades are engineered to deliver maximum uptime and productivity in metal recycling operations.

Extreme Impact Resistance

The 1211-A6 steel core is specifically formulated to handle the shock of cutting random, irregular steel pieces without chipping or cracking.

Enhanced Durability

Superior wear resistance extends service life dramatically, reducing the frequency of blade changes and associated downtime.

Optimized Cutting Power

The double-head design and robust geometry ensure efficient shearing and tearing action, maximizing throughput for 650/750/1000 type machines.

Precision Fit & Balance

Accurate dimensions and multiple hole patterns guarantee perfect installation and balanced rotation, minimizing vibration and machine wear.

Application Industries & Materials

These heavy-duty blades are purpose-built for the metal recycling and processing industry, specifically designed to handle the toughest materials.

Primary Application: Random Steel Shredding - Ideal for processing mixed steel scrap, including sheet metal, light structural steel, wire, rebar, and off-cuts from manufacturing, into uniform pellets or chips.

Target Industries: Metal recycling yards, scrapyards, automobile recycling (ELV), appliance recycling, and steel fabrication plants. These blades are the critical component in transforming bulky, mixed steel waste into a high-density, flowable feedstock that is ideal for melting in electric arc furnaces or for use in other metallurgical processes.

Customization & Quality Assurance

While we offer an extensive range of standard sizes (like the popular 100x100x28mm four-hole blade), we specialize in providing fully customized blade solutions. We can adapt dimensions, thickness, hole patterns, and even material heat treatment to match your specific double-head cutting machine model and the unique composition of your steel scrap stream.

Our commitment to quality is rigorous and transparent. Every order is supported by a machinery test report verifying material properties and performance specifications. Additionally, our unique video outgoing-inspection provides visual confirmation of each blade's quality before shipment. Packaged securely for international shipping, these blades arrive ready for installation and are backed by our 3-month warranty for your peace of mind.

Standard Lead Time:

| Quantity (pieces) | Lead Time (days) |

|---|---|

| 1 - 100 | 10 days |

| 101 - 300 | 20 days |

| 301 - 500 | 30 days |

| > 500 | To be negotiated |

Top 5 Steel Particle Machine Blade Brands

When investing in blades for heavy-duty steel shredding, choosing a reliable brand is critical for operational continuity. Here are five notable manufacturers in this specialized field.

1. ShengAo

Origin: Anhui, China

Strength: Specializes in 1211-A6 steel blades for double-head cutting machines. Offers an unmatched range of standard sizes and hole configurations, backed by machinery test reports, video inspection, and a 3-month warranty. A top choice for durability and value in random steel shredding applications.

2. Metso Outotec

A global leader in mineral and metal processing, offering heavy-duty shredder blades and wear parts for large-scale metal recycling plants, known for advanced materials engineering.

3. SSI Shredding Systems

Provides robust shredding solutions and replacement parts, including blades for ferrous scrap processing, with a focus on high-torque, low-speed shredder designs.

4. Hammel / Arjes

European manufacturers of shredding equipment that also supply high-quality, application-specific blades for their own and compatible machines, particularly in the scrap metal sector.

5. ForTech Recycling

Specializes in wear parts and blades for the recycling industry, with a strong offering in metal shredder blades, focusing on cost-per-ton performance.

Frequently Asked Questions (FAQ)

Find quick answers to common queries about steel pellet machine blades.