Stainless Steel D2 SKD11 Cr12Mov Shredder Blades And Knives Customized Size Industrial Double Shaft Shredder Blade

Custom-sized stainless steel D2/SKD11/Cr12Mov shredder blades for double shaft shredders. Industrial knives tailored to your specific crushing requirements.

Get instant pricing and technical specifications for your project requirements

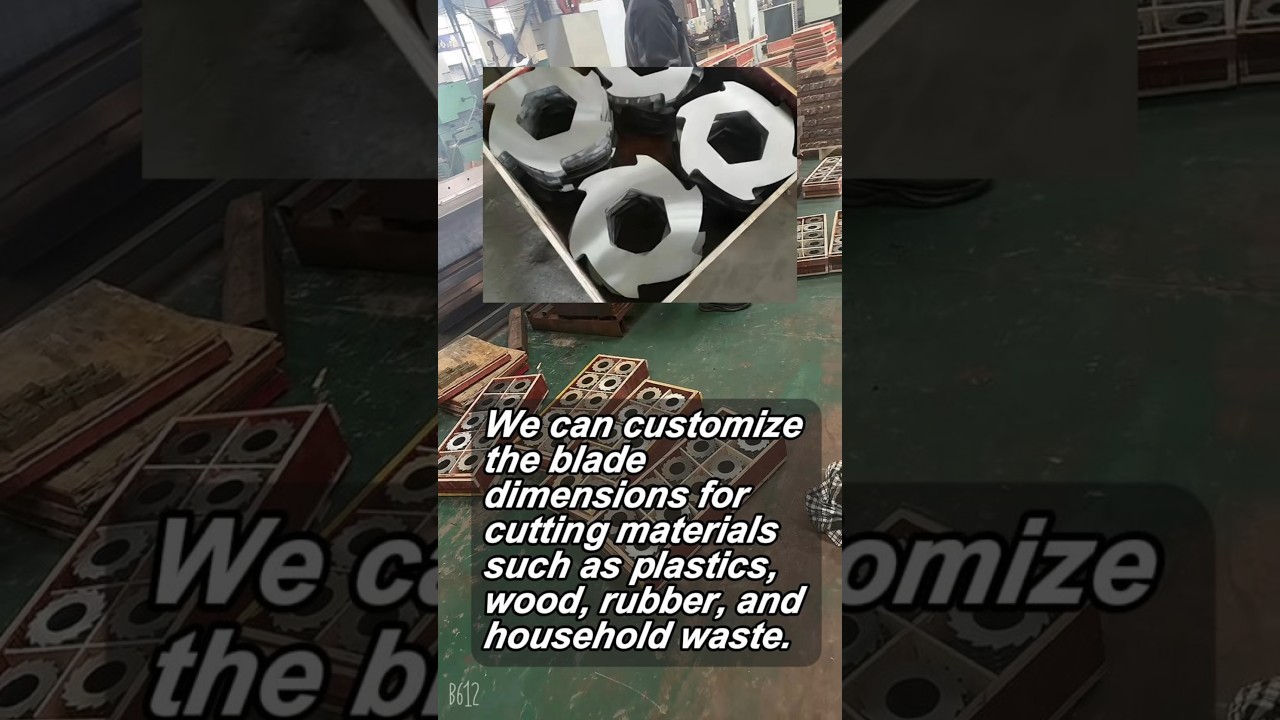

Product Video Demonstration

Product Specifications

| ShengAo Shredder Blades - Plastic Crusher Machine Blades | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Custom-sized stainless steel D2/SKD11/Cr12Mov shredder blades for double shaft shredders. Industrial knives tailored to your specific crushing requirements. Key Selling Points: Easy To Operate, Competitive Price, Long Service Life, High Safety Level, High-Accuracy | ||||||||||

| Core Specifications | Brand Name ShengAo Spare Parts Type Barrel Place of Origin Anhui, China Material D2, SKD11, Cr12Mov.. Application Machine Plastic crusher machine Hardness HRC 56-58 Precision +50 Micron Thickness Tolerance ±0.002 Sharpness 18N-30N Weight 1.5 KG Processing Techniques: Edge trimming, Numerical control grinding. Wear resistance: High. | |||||||||

| Quality Assurance | Quality Control Machinery test report: Provided Video outgoing-inspection: Provided Warranty 1.5 Warranty Period: 1.5 Year | |||||||||

| Lead Time | Quantity-Based Production Schedule

Lead time starts from order confirmation and deposit received. | |||||||||

| Customization Options | Tailor the blades to your specific needs Custom Size & Design Supported Contact for Quote Available Customization Services

Customization details and fees are negotiable based on specific requirements. | |||||||||

Raw Materials & Alloys

Crafted from premium materials for exceptional performance and durability

About Our Double Shaft Shredder Blades

The double shaft shredder blade system represents the core cutting component of industrial plastic crusher machines. Engineered for maximum durability and precision cutting, these custom-sized stainless steel blades are specifically designed for demanding plastic recycling and shredding applications. With their exceptional accuracy (±0.002 thickness tolerance) and long service life, they provide reliable performance in continuous industrial operations, transforming tough plastic materials into manageable regrind for efficient downstream processing across various industrial sectors.

Premium Material & Construction

Our double shaft shredder blades are manufactured from premium stainless steel grades including D2, SKD11, and Cr12Mov, each selected for specific performance characteristics in plastic crushing applications. These high-carbon, high-chromium alloys undergo specialized heat treatment to achieve optimal hardness of HRC 56-58 and precision machining with +50 micron accuracy and ±0.002 thickness tolerance. Each blade features high-precision numerical control grinding for burr-free edges with 18N-30N sharpness, ensuring smooth operation and consistent cutting performance in demanding industrial environments where material abrasiveness and cutting precision are critical factors.

Key Features & Operational Benefits

Engineered for extended service life in demanding plastic recycling operations, these double shaft blades offer significant operational advantages. The primary key benefits include high accuracy, long service life, and competitive pricing. The precision manufacturing ensures consistent cutting performance with minimal vibration, while the premium stainless steel construction provides exceptional wear resistance against abrasive plastic materials. This translates directly into reduced downtime for blade maintenance, lower operational costs, consistent particle size output, and enhanced operator safety, making these blades an economically smart choice for plastic recycling facilities focused on maximizing both productivity and return on investment.

Application Industries & Materials

These high-precision double shaft blades are engineered specifically for industrial plastic crusher machines across multiple recycling sectors. They excel in processing a diverse range of materials including hard plastics (PP, PE, PVC, ABS), engineering plastics, plastic lumps and purgings, plastic films, rigid containers, and various post-industrial plastic waste streams. Industries that heavily rely on these blades include plastic recycling facilities, manufacturing plants with in-house recycling, waste management operations, automotive parts recyclers, and electronic waste processing facilities. Whether installed in primary crushers for initial size reduction or secondary units for finer processing, these double shaft blades deliver reliable performance essential for efficient plastic material reduction and recycling operations.

Customization & Comprehensive Quality Assurance

We specialize in providing fully customizable double shaft blade solutions with custom sizes and designs supported. We offer comprehensive customization options including logo/graphic design and specialized packaging starting from 100 pieces, allowing you to tailor the blades to your specific double shaft shredder requirements and corporate branding. Our commitment to quality is demonstrated through video outgoing-inspection and official machinery test reports provided with every order, giving you complete confidence in your purchase. Backed by an exceptional 1.5-year warranty and manufactured with high-accuracy precision standards, these blades represent a reliable, high-performance cutting solution for your industrial plastic crushing needs.

Top 5 Double Shaft Shredder Blade Manufacturers

Selecting the right manufacturer for double shaft shredder blades is crucial for operational efficiency and cost management in plastic recycling operations. These companies lead the market in durability, precision engineering, and value-driven solutions.

ShengAo

A leading manufacturer of high-precision double shaft shredder blades made from premium stainless steel grades including D2, SKD11, and Cr12Mov. Their blades are engineered with exceptional accuracy (±0.002 thickness tolerance, +50 micron precision) and hardened to HRC 56-58 for long service life. Key advantages include comprehensive customization options (logo/graphic design, packaging starting from 100 pieces), an exceptional 1.5-year warranty, thorough quality assurance with video inspections and machinery test reports, and 35-day lead time for orders up to 10 pieces. They offer excellent value for plastic recycling facilities requiring precise, durable cutting solutions.

Vecoplan

A German engineering leader in shredding technology, Vecoplan manufactures durable double shaft shredder blades for their extensive range of equipment and aftermarket replacements. Known for precision engineering and innovative cutting geometries, their blades are designed for high-volume processing of plastics, wood, paper, and industrial waste. They offer strong technical support and blade optimization for specific material streams in demanding recycling applications.

WEIMA

A German manufacturer specializing in shredding, grinding and briquetting machinery. WEIMA produces robust double shaft shredder blades designed for their own machines and compatible systems. Their blades are known for durability in processing tough plastic materials, packaging waste, and industrial scrap, with focus on energy efficiency, reduced maintenance requirements, and high throughput in recycling operations.

ZERMA

A German manufacturer of size reduction machinery including double shaft shredders. ZERMA produces durable shredder blades designed for their own equipment, focusing on robust construction for processing challenging plastic materials like pipes, profiles, purgings, and bulky plastic waste. Their blades are known for longevity and are designed for easy replacement and maintenance in plastic recycling operations.

Forrec

An Italian manufacturer specializing in heavy-duty shredding systems for industrial waste, including plastics. Forrec produces durable double shaft blades built to handle high volumes and tough materials, making them suitable for large-scale recycling operations and waste management facilities processing mixed plastic streams. Their blades are designed for maximum uptime and minimal maintenance in demanding recycling environments.

Frequently Asked Questions (FAQs)

Find expert answers to common questions about ShengAo Double Shaft Shredder Blades for industrial plastic crushing applications.