Solid Fixed Blades Whitepaper

ShengAo Solid Fixed Blades: Ultimate Buy Guide for Industrial Cutting Applications

Table of Contents

- Introduction to Solid Fixed Blades

- Key Features and Technological Advantages

- Primary Applications of Solid Fixed Blades

- Material Options and Specifications

- How to Select the Right Solid Fixed Blade

- Installation and Maintenance Best Practices

- Why Choose ShengAo Solid Fixed Blades

- Conclusion: Enhancing Your Operations with ShengAo

- Contact ShengAo for Your Blade Requirements

Introduction to Solid Fixed Blades

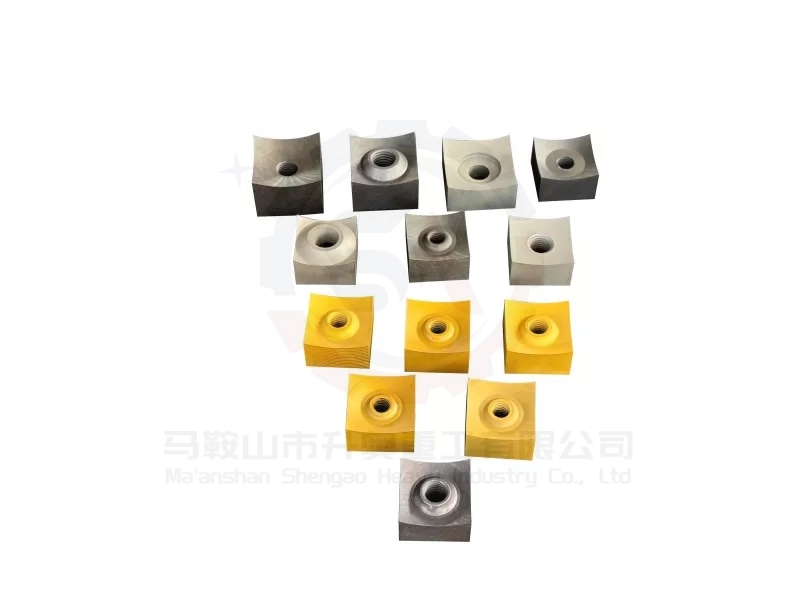

ShengAo Solid Fixed Blades represent the pinnacle of industrial cutting technology, engineered to deliver uncompromising performance in the most demanding material processing applications. Unlike standard blades, these precision-engineered cutting tools are manufactured from solid blocks of premium-grade steel using advanced CNC grinding and heat treatment processes. Designed specifically for heavy-duty shredding, plastic recycling, metal processing, and composite cutting operations, ShengAo blades maintain cutting integrity through extended service cycles while resisting deformation under extreme pressures. With global industrial blade market projected to reach $4.8 billion by 2027, the demand for specialized cutting solutions like ShengAo's fixed blades continues to grow across recycling, manufacturing, and waste processing sectors.

Key Features and Technological Advantages

Industrial-Grade Durability

ShengAo Solid Fixed Blades are manufactured using premium materials that undergo specialized heat treatment processes to achieve Rockwell hardness ratings of 58-62 HRC. This exceptional hardness enables the blades to maintain cutting integrity through extended service cycles while resisting deformation under extreme pressures. The proprietary hardening process creates a blade structure that withstands impact forces exceeding 1500 MPa without chipping or fracturing, making them ideal for processing challenging materials like automotive scrap, e-waste, and reinforced plastics.

Precision Engineering

Every ShengAo blade undergoes CNC precision grinding with tolerances maintained within ±0.01mm, ensuring consistent cutting performance and perfect alignment in industrial cutting systems. This level of precision is critical for applications requiring clean cuts without material deformation, such as plastic granulation and metal shearing. The blades feature optimized cutting geometries with edge angles ranging from 12° to 18° depending on application requirements, balancing sharpness for clean cuts with durability for extended service life.

Specialized Coatings

ShengAo offers advanced surface treatments that extend blade life by up to 300% compared to uncoated alternatives:

- TiN (Titanium Nitride): Gold-colored coating reducing friction by 40%

- TiCN (Titanium Carbonitride): Blue-gray coating with superior abrasion resistance

- AlTiN (Aluminum Titanium Nitride): For extreme temperature applications

- CrN (Chromium Nitride): Corrosion-resistant coating for wet environments

Customization Capabilities

ShengAo provides comprehensive customization services to meet unique operational requirements. Engineers can tailor blade dimensions, tooth configurations, material composition, and coating specifications to match specific cutting challenges. Custom solutions include specialized carbide inserts for high-abrasion applications, hybrid steel compositions for impact resistance, and unique tooth geometries for specific material types.

Primary Applications of Solid Fixed Blades

Heavy-Duty Shredding

ShengAo blades process diverse materials including:

- Automotive scrap and ELV (End-of-Life Vehicles)

- Industrial waste and demolition debris

- E-waste and electrical components

- Tires and rubber products

Our blades maintain cutting efficiency even when processing mixed-material streams containing metals, plastics, and composites.

Plastic Recycling

Optimized for processing all polymer types:

| Plastic Type | Recommended Blade | Edge Angle | Coating |

|---|---|---|---|

| PET/PETE | HSS with TiCN | 14° | TiCN |

| HDPE | Tool Steel | 16° | CrN |

| PVC | Stainless Steel | 12° | AlTiN |

| PP | Carbide-Tipped | 18° | TiN |

Metal Processing

ShengAo blades handle ferrous and non-ferrous metals up to 10mm thickness with specialized blade configurations for different metal types. Our blades maintain cutting performance through 500+ operating hours even when processing hardened steel and alloys.

Composite Material Cutting

Engineered solutions for advanced composites including carbon fiber, fiberglass, and Kevlar-reinforced materials. Specialized edge geometries prevent delamination and fraying while carbide-enhanced blades withstand the abrasive nature of composite materials.

Material Options and Specifications

High-Speed Steel (HSS)

M2 and M35 grade HSS blades offer excellent toughness and wear resistance for general-purpose applications. Heat treated to 60-63 HRC with optional coatings.

Carbide Steel

Tungsten carbide blades provide maximum wear resistance for highly abrasive materials. Ideal for glass-filled plastics, mineral-filled compounds, and carbon fiber processing.

Tool Steel Variants

D2, D3, and A2 tool steels balance hardness and impact resistance for demanding shredding applications. Through-hardened to 58-60 HRC with deep hardening properties.

Technical Specifications Table

| Parameter | Standard Range | Custom Options | Measurement |

|---|---|---|---|

| Hardness | 58-62 HRC | Up to 65 HRC | Rockwell C Scale |

| Thickness | 10-50mm | 5-100mm | Millimeters |

| Width | 50-300mm | 30-500mm | Millimeters |

| Length | 100-2000mm | 50-3000mm | Millimeters |

| Edge Angle | 12°, 14°, 16° | 10°-20° | Degrees |

| Surface Finish | Ra 0.4μm | Ra 0.2μm | Micrometers |

How to Select the Right Solid Fixed Blade

Material Compatibility

Match blade material to processed materials:

- Carbide: Glass-filled plastics, minerals, carbon fiber

- HSS: General plastics, non-ferrous metals

- Tool Steel: Ferrous metals, mixed waste streams

Cutting Environment Considerations

Select coatings based on operating conditions:

- Wet Processing: CrN coating for corrosion resistance

- High-Temperature: AlTiN coating maintains hardness

- Abrasive Materials: TiCN coating reduces wear

Blade Dimensions and Geometry

Optimize cutting efficiency with proper geometry selection:

- 12° Edge: Sharpest cut for soft materials

- 16° Edge: Balanced sharpness and durability

- 18° Edge: Maximum durability for hard materials

Installation and Maintenance Best Practices

Proper Installation Procedures

Ensure correct blade mounting with torque specifications of 80-120 N·m depending on blade size. Always use calibrated torque wrenches and follow parallel alignment procedures to prevent premature wear.

Routine Maintenance Tips

- Inspect blades every 40 operating hours

- Rotate blades regularly to distribute wear evenly

- Clean blade seats during changeovers

- Measure edge wear with precision gauges

Troubleshooting Common Issues

| Problem | Possible Cause | Solution |

|---|---|---|

| Premature Wear | Incorrect blade material selection | Upgrade to carbide or specialized coating |

| Edge Chipping | Excessive impact or misalignment | Check mounting alignment and torque |

| Reduced Cutting Efficiency | Blunt edge or incorrect geometry | Resharpen or replace with proper edge angle |

| Vibration | Uneven wear or imbalance | Rotate blades or replace set |

Why Choose ShengAo Solid Fixed Blades

Quality Assurance

Every blade undergoes 12-stage quality control including spectrometer material verification, hardness mapping, dimensional inspection, and cutting performance testing. Our ISO 9001-certified manufacturing ensures consistent quality across production batches.

Custom Engineering Services

ShengAo provides comprehensive engineering support including:

- Material analysis and blade recommendation

- CAD modeling and prototype development

- Application-specific heat treatment protocols

- Performance validation testing

Global Support and Service

With technical support available in 12 languages and distribution centers across North America, Europe, and Asia, ShengAo delivers responsive service including:

- Emergency blade replacement within 72 hours

- On-site technical consultation

- Blade sharpening and reconditioning services

- Performance optimization analysis

Conclusion: Enhancing Your Operations with ShengAo

ShengAo Solid Fixed Blades deliver unmatched performance in the most demanding industrial cutting applications. By combining premium materials, precision engineering, and specialized coatings, our blades extend service intervals by 40-60% while maintaining cutting precision throughout their lifecycle. With comprehensive customization capabilities and global technical support, ShengAo provides cutting solutions optimized for your specific operational requirements. Experience the ShengAo difference in reduced downtime, lower operational costs, and improved processing efficiency across shredding, recycling, and material processing applications.

Contact ShengAo for Your Blade Requirements

For technical specifications, custom blade inquiries, or volume pricing:

Engineer Jack

Email: jack@shenaozg.com

Mobile: +86 136 9673 1068

WhatsApp: +86 152 1234 9604

Address: Bowang town Songhua River road, Bowang District, Ma'anshan City, China