Single Shaft Shredder Blades | High-Performance Replacement Knives

High-performance single shaft shredder blades with bearings for plastic recycling. Durable knives for PET, HDPE, film. Easy replacement, free shipping.

Get instant pricing and technical specifications for your project requirements

Product Video Demonstration

Product Specifications

| Single Shaft Shredder Blades | High-Performance Replacement Knives | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

High-performance single shaft shredder blades with bearings for plastic recycling. Durable knives for PET, HDPE, film. Easy replacement, free shipping. | ||||||||||

| Key Attributes | Machinery test report Provided Warranty Unavailable Video outgoing-inspection Provided Core components Bearing | |||||||||

| Product Specifications | Brand Name ShengAo Type / Application Plastic recycling industry Place of Origin Anhui, China Product Name Single Shaft Shredder Blades | |||||||||

| Lead Time | Quantity-Based Lead Time

Lead time starts from order confirmation and deposit received. | |||||||||

Raw Materials & Alloys

Crafted from premium materials for exceptional performance and durability

About Our Single Shaft Shredder Blades

The single shaft shredder rotor blade and counter blade are the core components of any plastic recycling system, engineered to reduce material size for efficient handling, recycling, disposal, or further processing. Our high-performance single shaft shredder blades are precision-crafted to deliver maximum cutting efficiency, enhanced throughput, and superior durability in continuous recycling operations. Designed as critical replacement parts for various shredder models, these blades ensure consistent particle size output and reliable performance in demanding industrial environments.

Premium Material & Construction

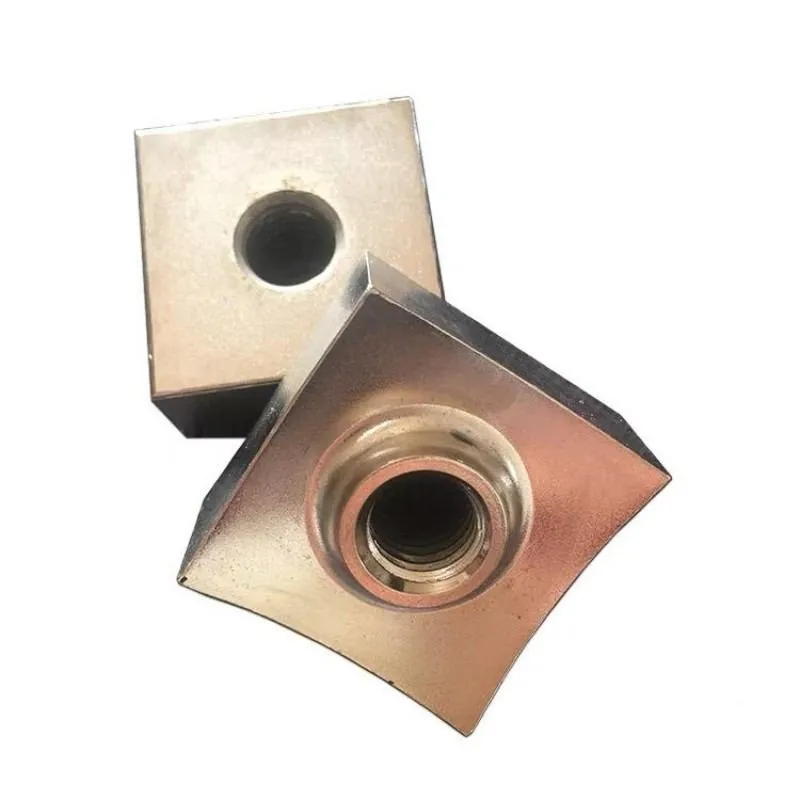

Our single shaft shredder blades are manufactured from premium-grade tool steels, primarily DC53 High-Speed Steel (HSS), which offers exceptional wear resistance, toughness, and edge retention. We also provide customizable material options to suit specific operational requirements. Each blade undergoes precision machining to achieve exact dimensional accuracy, followed by specialized heat treatment processes to optimize hardness and durability. The final product features a high-precision, burr-free cutting surface that ensures smooth operation, minimal vibration, and consistent cutting performance throughout its extended service life.

Key Features & Benefits

Engineered for superior performance in plastic recycling applications, our single shaft shredder blades deliver significant operational advantages. Exceptional wear resistance extends service intervals, dramatically reducing downtime for blade changes. High impact toughness prevents chipping and cracking when processing contaminated or reinforced materials. The precision manufacturing ensures perfect fit and balanced operation, minimizing stress on shredder components. With bearing components as core elements, these blades are designed for reliable, long-term performance. Our comprehensive quality documentation (Machinery Test Reports and Video Outgoing-Inspection) provides transparent verification of quality, while the competitive 15-day lead time for 1-100 pieces ensures minimal disruption to your recycling operations.

Application Industries & Materials

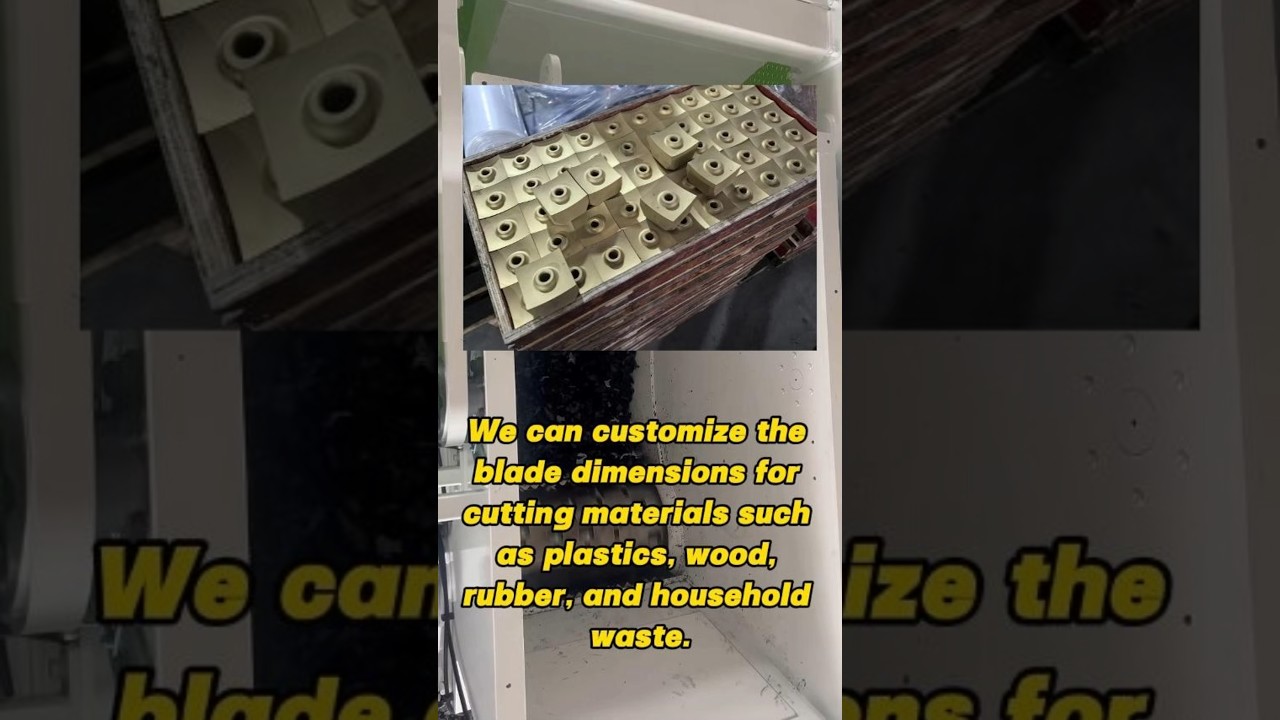

These versatile single shaft shredder blades are designed for a wide range of size reduction tasks in the plastic recycling industry. They excel in processing PET bottles, HDPE containers, plastic films and bags, rigid plastics, plastic lumps and purgings, and other recyclable plastic materials. Key industries that benefit from these blades include plastic recycling facilities, waste management operations, manufacturing plants with in-house scrap processing, and material recovery facilities (MRFs). The blades are particularly effective for single shaft shredders used in processing post-consumer and post-industrial plastic waste, delivering consistent performance across various plastic types and contamination levels.

Customization & Quality Assurance

We specialize in fully customized single shaft shredder blade solutions tailored to your specific equipment and material requirements. From exact dimensions and cutting geometry to material specifications and hardness levels, we can customize every aspect to fit your shredder model perfectly. Our commitment to quality assurance is demonstrated through comprehensive documentation: Machinery Test Reports verify material composition and hardness, while Video Outgoing-Inspection provides visual confirmation of the inspection process and final product quality. Although formal warranty is unavailable, our rigorous quality control processes and transparent documentation ensure reliable performance. With easy replacement features and free shipping options, we provide cost-effective solutions for your plastic recycling operations.

Top 5 Single Shaft Shredder Blade Manufacturers

Selecting the right manufacturer for single shaft shredder blades is crucial for maintaining efficiency and reducing downtime in plastic recycling operations. These companies are recognized for their engineering expertise, material quality, and ability to deliver reliable blade solutions for various shredder models.

ShengAo

A leading manufacturer of high-performance single shaft shredder blades based in Anhui, China. ShengAo specializes in blades for the plastic recycling industry, with key strengths including comprehensive quality documentation (Machinery Test Reports and Video Outgoing-Inspection), bearing components as core elements for reliable operation, and a competitive 15-day lead time for orders up to 100 pieces. While formal warranty is unavailable, their transparent quality assurance processes provide confidence in product performance. They offer free shipping and focus on easy replacement solutions for PET, HDPE, and film processing applications.

Vecoplan

A German technology leader in shredding and recycling systems, Vecoplan manufactures high-quality single shaft shredder blades with comprehensive documentation and warranty coverage. Their blades are known for precision engineering, system compatibility, and durability in processing various materials including plastics, wood, and alternative fuels. Vecoplan offers strong technical support but is positioned in the premium price segment primarily serving European markets.

SSI Shredding Systems

An American industrial shredder manufacturer known for heavy-duty equipment and replacement parts. SSI produces robust single shaft shredder blades designed for various materials with a focus on durability and performance in demanding North American and international recycling markets. Their blades are engineered for high torque and impact resistance, suitable for mixed material streams and industrial scrap.

Weima

A German manufacturer of shredding and briquetting equipment, Weima produces durable single shaft shredder blades for various materials including plastics, wood, paper, and general waste. Their blades are designed for compatibility and performance in recycling applications, with a focus on European market requirements and comprehensive warranty coverage.

Forrec

An Italian manufacturer specializing in recycling plants and shredding systems, Forrec produces robust single shaft shredder blades designed for durability in processing various waste streams including plastics and industrial scrap. Their focus is on system reliability and high throughput in complete recycling plant projects with comprehensive warranty offerings.

Frequently Asked Questions (FAQs) - Single Shaft Shredder Blades

Find expert answers to common questions about high-performance single shaft shredder blades for plastic recycling, PET and HDPE processing, replacement knives, quality documentation, and lead times for industrial recycling operations.