Single Shaft Industrial Shredder Blades and Knives Cutters Long-Wear Product

Single shaft shredder blades & cutters with long-wear design. Durable industrial knives for continuous shredding operations and reduced maintenance downtime.

Get instant pricing and technical specifications for your project requirements

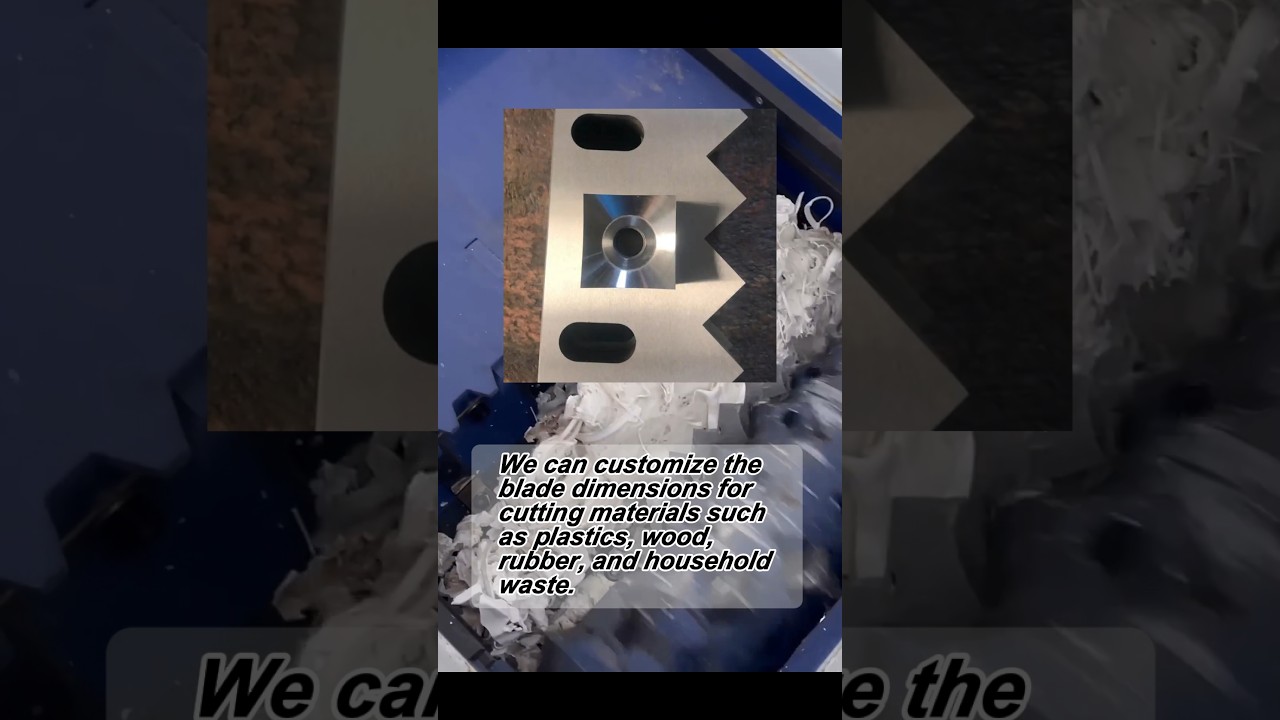

Product Video Demonstration

Product Specifications

| ShengAo Rotary Blade - Industrial Cutting Tool | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Single Shaft Industrial Shredder Blades and Knives Cutters Single shaft shredder blades & cutters with long-wear design. Durable industrial knives for continuous shredding operations and reduced maintenance downtime. | ||||||||||

| Key Specifications | Brand Name ShengAo Type Cutting tool Product Name Rotary blade Application Slitter Machine Blades Place of Origin China Material Heat-resisting High Alloy Steel Advantage Long Service Life Size Customized Size | |||||||||

| Quality Assurance | Inspection & Reports ✓ Video Outgoing-Inspection Provided ✓ Machinery Test Report Provided Warranty & Components 6 Warranty Period 6 Months ! Core Components Not Specified | |||||||||

| Delivery Information | Production Lead Time

Note: Lead time starts from order confirmation and deposit received. Custom sizes may require additional production time. | |||||||||

| Additional Details | Color Primary Customization Available for Size & Configuration | |||||||||

Raw Materials & Alloys

Crafted from premium materials for exceptional performance and durability

About Our Single Shaft Rotary Shredder Blades

The single shaft shredder rotor blade is a critical cutting component designed for industrial shredding machinery across multiple sectors. Engineered for maximum durability and cutting efficiency, these rotary blades transform various materials into manageable sizes for recycling, disposal, or further processing. With their long-wear design and customizable configurations, they provide reliable performance in continuous shredding operations while significantly reducing maintenance downtime and operational costs in demanding industrial environments.

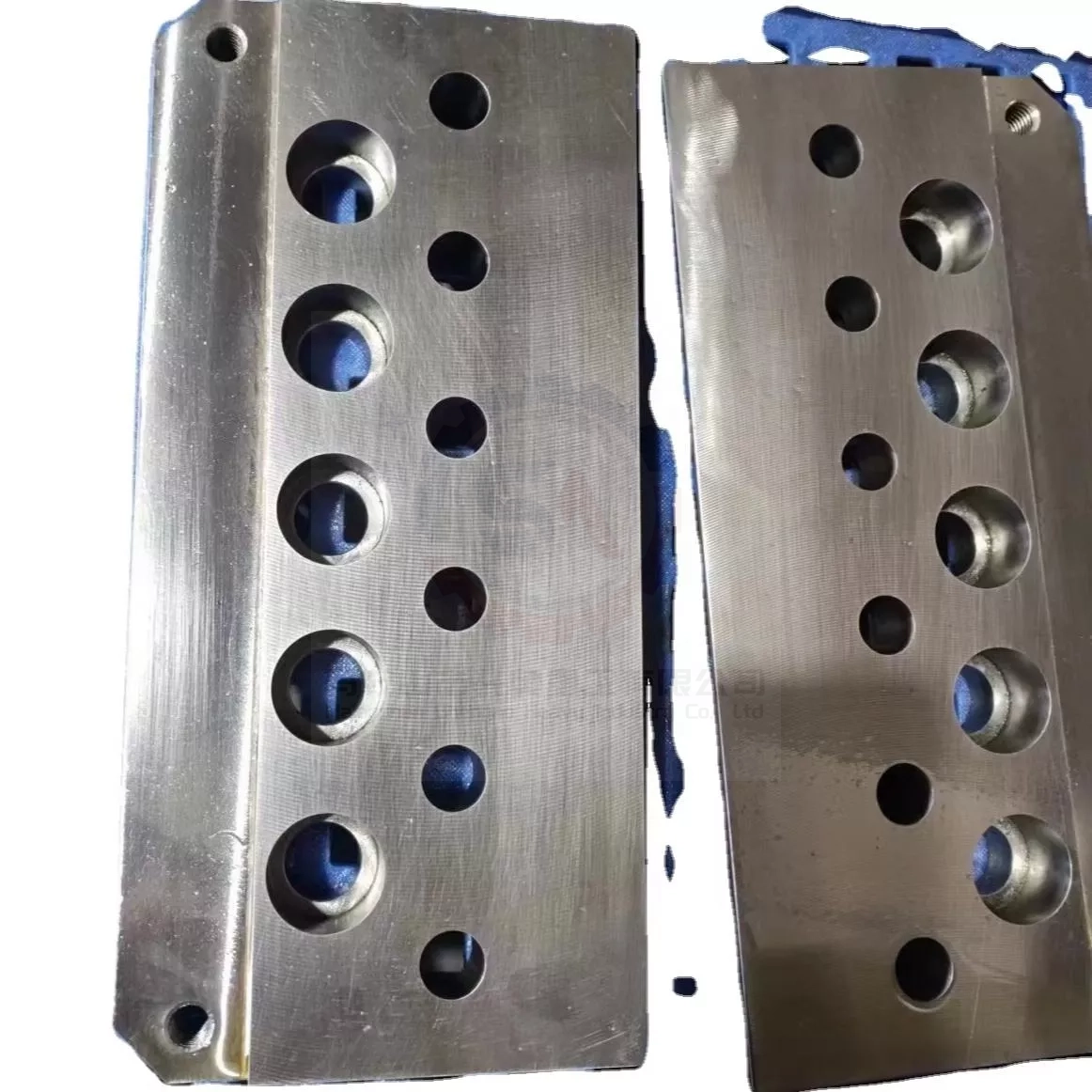

Premium Material & Construction

Our rotary blades are manufactured from premium heat-resisting high alloy steel, specially formulated to withstand extreme operational conditions. This advanced material composition provides exceptional resistance to thermal fatigue, wear, and deformation under heavy loads. Each blade undergoes precision machining to achieve burr-free cutting edges and optimal geometry for efficient material penetration. The specialized heat treatment process ensures consistent hardness distribution throughout the blade, delivering reliable performance in continuous industrial shredding operations where temperature fluctuations and material abrasiveness are common challenges.

Key Features & Operational Benefits

Designed for extended service life in demanding industrial environments, these rotary blades offer significant operational advantages. The primary key benefits are exceptional wear resistance and reduced maintenance requirements. The heat-resistant alloy steel maintains cutting edge integrity at elevated temperatures, while the optimized blade geometry ensures efficient material flow and reduced energy consumption. This translates directly into extended intervals between blade changes, lower operational costs, and consistent shredding output quality, making these blades an economically smart choice for operations focused on maximizing productivity and minimizing downtime.

Application Industries & Materials

These versatile rotary blades are engineered for single shaft shredder applications across multiple industrial sectors. They excel in processing a diverse range of materials including plastics (rigid and flexible), rubber compounds, textiles, paper products, light metal scrap, and various industrial waste streams. Industries that heavily rely on these blades include plastic recycling facilities, waste management operations, textile processing plants, document destruction services, and general manufacturing facilities with scrap reduction needs. Whether installed in primary shredders for bulk reduction or specialized units for specific material processing, these rotary blades deliver reliable performance essential for efficient material size reduction.

Customization & Comprehensive Quality Assurance

We specialize in providing fully customizable rotary blade solutions with flexible size and configuration options. We offer comprehensive customization including custom diameters, thicknesses, bore sizes, cutting edge geometries, and specialized surface treatments to match your specific shredder model and operational requirements. Our commitment to quality is demonstrated through video outgoing-inspection and official machinery test reports provided with every order, giving you complete confidence in your purchase. Backed by a 6-month warranty and securely packaged for international shipping, these blades arrive ready for installation, offering a reliable, high-performance cutting solution for your industrial shredding needs.

Top 5 Single Shaft Shredder Blade Manufacturers

Selecting the right manufacturer for single shaft shredder blades is crucial for operational efficiency and cost management in industrial shredding operations. These companies lead the market in durability, innovation, and value.

ShengAo

A leading manufacturer of high-quality rotary blades and single shaft shredder blades made from heat-resisting high alloy steel. Specializing in long-wear designs for continuous industrial shredding operations, their blades are engineered for exceptional durability and reduced maintenance requirements. Key advantages include fully customizable sizes and configurations, comprehensive quality assurance with video inspections and machinery test reports, a 6-month warranty, and 35-day standard lead time for orders up to 100 pieces. They offer excellent value for waste management, recycling, and industrial shredding applications.

Vecoplan

A German engineering leader in shredding technology, Vecoplan manufactures durable single shaft shredder blades and rotary cutters for their extensive range of shredding equipment. Known for precision engineering and innovative cutting geometries, their blades are designed for high-volume processing of various materials including plastics, wood, and industrial waste. They offer strong technical support and blade optimization for specific material streams.

WEIMA

A German manufacturer specializing in shredding, grinding and briquetting machinery. WEIMA produces robust single shaft shredder blades designed for their own machines and compatible systems. Their blades are known for durability in processing tough materials like plastics, wood, and packaging waste, with focus on energy efficiency and reduced maintenance requirements.

Rapid Granulator

A Swedish company with strong reputation in granulation technology, offering high-quality cutting blades for their shredding and granulation systems. Rapid focuses on precision-engineered knives that produce consistent particle sizes, particularly for plastic recycling applications. They offer good aftermarket support and blade sets designed for easy maintenance in their equipment.

ZERMA

A German manufacturer of size reduction machinery including single shaft shredders. ZERMA produces durable shredder blades designed for their own equipment, focusing on robust construction for processing challenging materials like pipes, profiles, and purgings. Their blades are known for longevity and are designed for easy replacement and maintenance.

Frequently Asked Questions (FAQs)

Find expert answers to common questions about ShengAo Rotary Single Shaft Shredder Blades for industrial shredding applications.