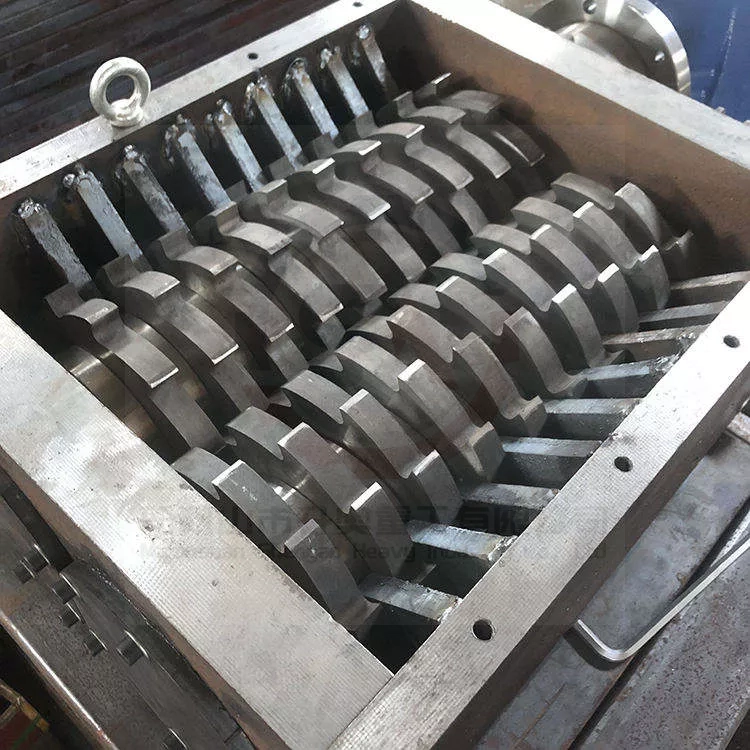

Shredder Tool Box Accessories Paper Shredder Kninves Double Shaft Blades for Waste Wood Plastic Crusher

Double shaft shredder blades for waste wood, plastic, and crushers. Durable knives designed for shredder tool boxes. Ideal for industrial recycling and size reduction. Optimized for long life and efficient cutting.

Get instant pricing and technical specifications for your project requirements

Product Video Demonstration

Product Specifications

| Shredder Blades Crusher Knives | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

ShengAo Shredder Blades - Single/Double Shaft Blades for Industrial Recycling Double shaft shredder blades for waste wood, plastic, and crushers. Durable knives designed for shredder tool boxes. Ideal for industrial recycling and size reduction. Optimized for long life and efficient cutting. | ||||||||||

| Product Specifications | Brand Name ShengAo Type Single/Double Shaft Shredder Blade Material D2, HSS, SKD11, SKH-9, SK-51, T10, etc Hardness 58-68 HRC or Customized Applicable Materials cardboard, plastic, rubber, tires, resin, nylon, metal, etc Place of Origin Anhui, China MOQ 3 set OEM Acceptable Features Durable Application Machine Recycling Machine, Shredding Machine, Crusher, etc Service 24 hours online service | |||||||||

| Quality Assurance | Quality Control Machinery test report: Provided Video outgoing-inspection: Provided Warranty & Core Components ! Warranty: Unavailable B Core Components: Shredder Blade | |||||||||

| Delivery Information | Standard Delivery Time 15 days for 1-500 pieces Standard Lead Time Quantity-Based Lead Time

Lead time starts from order confirmation and deposit received | |||||||||

| Customization Options | Available Customizations

Other customization options available upon inquiry. OEM acceptable. | |||||||||

Raw Materials & Alloys

Crafted from premium materials for exceptional performance and durability

About Our Single & Double Shaft Shredder Blades

The shredder rotor blade and counter blade are the core components of any industrial shredding system. As the main component used in plastic recycling and waste size reduction, they perform the essential task of breaking down materials into smaller, manageable pieces. Our custom-made blades, including the popular 40mm square blade design, are engineered for maximum performance, durability, and efficiency in the most demanding industrial recycling environments.

Premium Material & Construction

Our blades are manufactured from a selection of high-performance tool steels to match your specific application. Options include D2, SKD-11, SKH-9, DC53 (HSS), and Cr12MoV. For processing tough materials like metal and thick plastics, we recommend SKD-11 or D2, heat-treated to achieve an optimal hardness of HRC 58-62 for exceptional wear resistance. Each blade undergoes precision machining and specialized heat treatment processes. Advanced manufacturing techniques, such as multi-layer hardfacing (build-up welding) with controlled weld bead height, are employed to further enhance surface hardness and longevity.

Key Features & Benefits

Engineered for superior performance, our shredder blades deliver significant operational advantages. The high hardness (HRC 58-68) ensures extended service life and consistent cutting performance, reducing the frequency of sharpening or replacement. Blade geometry is critically important; research indicates that a 35° cutting edge angle and a spiral orientation for double-edged blades can optimize the “grabbing curve” and achieve recycling efficiencies above 97% for materials like PET plastic. Our designs focus on providing excellent wear resistance to handle abrasive materials, high toughness to withstand impact, and configurations that promote efficient material flow and reduce uneven loading on the machine.

Application Industries & Materials

These versatile blades are built for a vast range of industrial shredding tasks across multiple sectors. They are highly effective in processing plastics (hard plastics, lumps, films), tires, rubber, various metals, wood, cardboard, and composite materials. Industries that rely on our blades include metal recycling, plastic recycling, waste management (MSW), electronic waste (WEEE) processing, tire recycling, and wood processing. Whether installed in a low-speed, high-torque dual-shaft shredder for coarse reduction or a single-shaft system for finer output, our blades provide reliable performance.

Customization & Quality Assurance

We specialize in providing fully customized shredder blade solutions. All dimensions, hole patterns, number of hooks (from 3 to 12), edge geometries, and material grades can be tailored to fit your specific shredder model and material stream. Our commitment to quality is demonstrated through comprehensive documentation, including official machinery test reports and video outgoing-inspection for every order. We support our products with reliable services, and our blades are securely packaged in robust wooden cases to ensure they arrive undamaged and ready for installation. For maintenance, we note that advanced hardfacing repair techniques can significantly extend blade life and reduce overall operating costs.

Top 5 Industrial Shredder Blade Brands for Recycling

Selecting high-quality shredder blades is critical for efficient and cost-effective recycling operations. These manufacturers are recognized for their material expertise, engineering precision, and proven performance in demanding size-reduction applications.

ShengAo

A leading manufacturer specializing in high-quality single and double shaft shredder blades for industrial recycling. Their blades are made from premium tool steels like D2, SKD11, and HSS, heat-treated to HRC 58-68 for optimal wear resistance and toughness. They offer full customization, accept OEM orders, and stand out with comprehensive quality assurance including machinery test reports and video outgoing-inspection. With a competitive minimum order quantity (MOQ) and a standard 15-day lead time, they are a reliable global supplier for recycling operations.

Vecoplan

The German engineering leader is renowned for its high-performance shredders and their original equipment blades. Vecoplan blades are designed for precision, extreme durability, and are often optimized for specific material streams like plastics, wood, and waste-derived fuels. They are known for innovative designs that maximize throughput and minimize wear, making them a top choice for large-scale, continuous industrial recycling applications, particularly in Europe and North America.

SSI Shredding Systems

An American pioneer in shredding technology, SSI manufactures robust, application-specific shredder blades for their renowned quad-shaft and dual-shear shredders. Their blades are built to handle the toughest materials, including mixed construction & demolition waste, industrial scrap, and tires. Focused on high torque and low-speed cutting action, SSI blades are designed for maximum longevity and reduced maintenance in heavy-duty size reduction.

WEIMA

Another prominent German manufacturer, WEIMA produces durable and efficient shredder blades for their extensive range of single, double, and four-shaft machines. Their blades are engineered for energy efficiency, easy maintenance, and consistent particle size output. WEIMA offers various blade geometries (e.g., hook shapes, cutting angles) optimized for different materials like plastics, wood, paper, and non-ferrous metals, making them a versatile choice for diverse recycling and waste processing needs.

Forrec

An Italian specialist in recycling technology, Forrec designs and manufactures robust shredder blades for their high-capacity systems. Their focus is on processing challenging material flows, including municipal solid waste (MSW), bulky waste, and end-of-life vehicles (ELVs). Forrec blades are built to withstand shock loads and contamination, featuring designs that promote self-cleaning and reduce the risk of jamming, which is crucial for handling heterogeneous waste streams.

Frequently Asked Questions (FAQs)

Find expert answers to the most common questions about Industrial Single and Double Shaft Shredder Blades for recycling and waste processing.