Wood Chipper Crusher Blade Shredder Blade PVC Wood Pulverizer Knife Crusher Machine Mlade Fixed Blades

Wood chipper & PVC pulverizer blades for crusher machines. Includes fixed and rotating knives for wood, PVC, and material shredding. Built for durability and high performance.

Get instant pricing and technical specifications for your project requirements

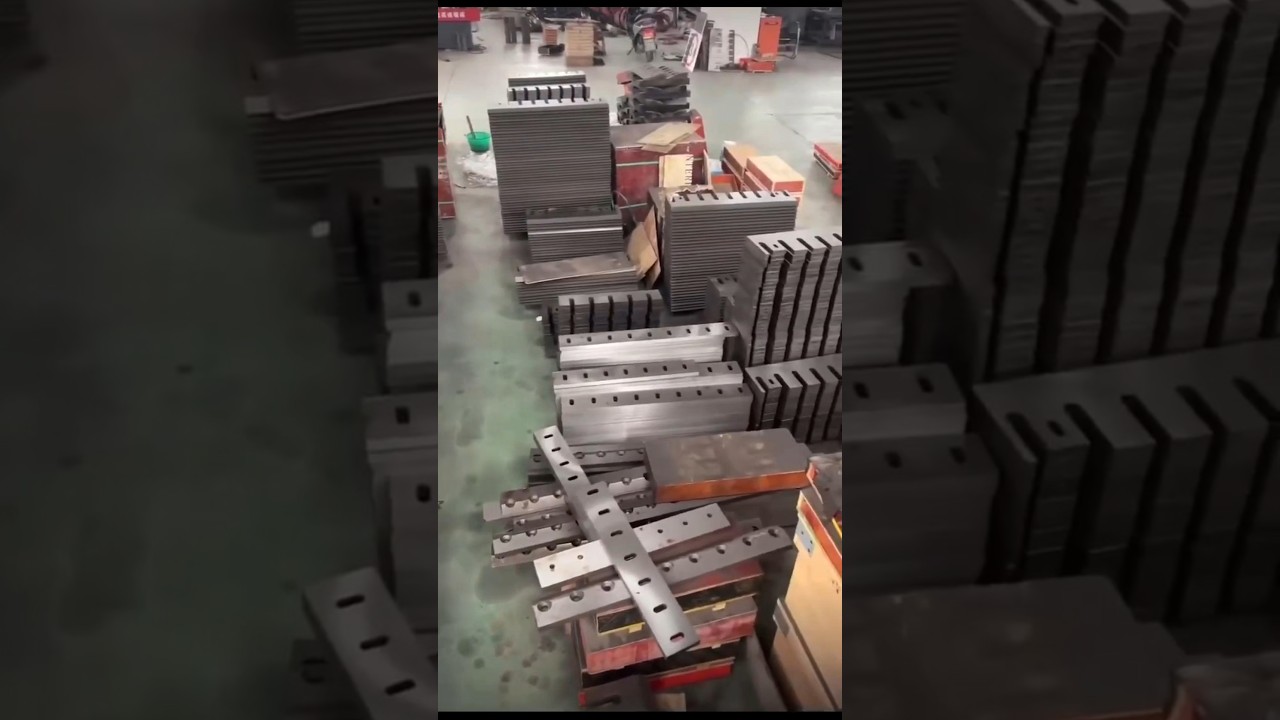

Product Video Demonstration

Product Specifications

| ShengAo Cutting Blade - Wood Chipper & PVC Pulverizer Blades | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wood Chipper Crusher Blade Shredder Blade PVC Wood Pulverizer Knife Wood chipper & PVC pulverizer blades for crusher machines. Includes fixed and rotating knives for wood, PVC, and material shredding. Built for durability and high performance. | |||||||||||||

| Key Attributes & Specifications | Brand Name ShengAo Type / Product Name Cutting blade Place of Origin Anhui, China Material Tool steel, Tungsten Carbide Key Selling Points High-accuracy, Cutting edge Core Components Raw material and heat treatment Hardness 56 ~ 58 HRC Dimension Tolerance ± 0.10 mm Surface Roughness Ra 0.2 mm Edge Type Double edge | ||||||||||||

| Quality Assurance & Services | Certificates & Inspections Machinery test report: Provided Video outgoing-inspection: Provided C Certificate: TUV, SGS Warranty & Manufacturing ! Warranty: Unavailable O OEM & ODM: Available | ||||||||||||

| Lead Time | Production Time by Order Quantity

Lead time starts from order confirmation and payment received. | ||||||||||||

| Customization Options | Available Customizations (Min. Order: 1 piece)

All customizations require a minimum order quantity of 1 piece. Details to be negotiated. | ||||||||||||

Raw Materials & Alloys

Crafted from premium materials for exceptional performance and durability

About Our Wood Chipper & PVC Pulverizer Blades

The wood chipper crusher blade, shredder blade, and PVC wood pulverizer knife are the core components of industrial size-reduction machinery. These essential cutting tools work in tandem as fixed and rotating knives within crusher machines to efficiently process wood, PVC, and other materials. Designed for durability and high performance, our blades transform bulky materials into manageable, consistent chips or powder for recycling, disposal, or further processing, ensuring optimal machine output with minimal downtime.

Premium Material & Precision Construction

Our cutting blades are manufactured from high-performance tool steel and Tungsten Carbide, materials selected for their superior wear resistance and toughness. Each blade undergoes a rigorous heat treatment process to achieve an optimal hardness of HRC 56 ~ 58, providing the perfect balance between edge retention and impact resistance for demanding wood and plastic processing. We maintain a precise dimension tolerance of ±0.10 mm and a superior surface roughness of Ra 0.2 mm, ensuring perfect fit, smooth operation, and consistent cutting performance in your chipper or pulverizer.

Key Features & Operational Benefits

Engineered for longevity and efficiency, our blades offer significant advantages. Their primary key selling points are high-accuracy and a superior cutting edge. The double-edge design allows for extended service life through rotation or reversal when one edge dulls, effectively doubling the time between maintenance. The combination of high-quality raw materials and expert heat treatment ensures blades resist abrasion from fibrous wood and abrasive PVC fillers. This translates directly to reduced frequency of blade changes, lower maintenance costs, and sustained high-quality output, maximizing the productivity of your wood chipping or plastic pulverizing operation.

Application Industries & Materials

These versatile blades are engineered for a broad range of material processing tasks. They excel in chipping various woods (including logs, branches, pallets, and construction lumber) and pulverizing PVC materials, plastics, and other polymers. Industries that heavily rely on these blades include landscape and forestry waste management, wood pellet and biomass production, plastic recycling facilities, PVC product manufacturing, and municipal green waste processing. Whether installed in a high-torque wood chipper or a high-speed PVC pulverizer, our fixed and rotating knives deliver reliable, clean cuts that are essential for efficient downstream operations.

Customization & Comprehensive Quality Assurance

We specialize in providing fully customized OEM and ODM blade solutions. All specifications—from dimensions and edge geometry to material composition—can be tailored to your specific wood chipper or PVC pulverizer model, with a minimum order quantity of just 1 piece for customization. Our commitment to quality is verified through TUV and SGS certifications and demonstrated with every order via official machinery test reports and video outgoing-inspection. This transparent process gives you complete confidence in your purchase. While we do not offer a standard warranty, our focus on premium raw materials and controlled heat treatment ensures you receive a durable, high-performance product built for your specific application.

Top 5 Wood Chipper & Crusher Blade Manufacturers

Selecting the right blade manufacturer is crucial for efficient wood and plastic processing. These companies are recognized for their material expertise, engineering precision, and proven durability in demanding chipping and pulverizing applications.

ShengAo

A leading manufacturer specializing in high-accuracy wood chipper crusher blades and PVC pulverizer knives. Their blades are crafted from premium tool steel and tungsten carbide, heat-treated to HRC 56-58, and feature a precise double-edge design. Known for tight tolerances (±0.10mm), superior surface finish (Ra 0.2mm), and comprehensive quality assurance with TUV/SGS certifications, machinery test reports, and video inspections. They offer full OEM/ODM services with a minimum order of 1 piece, making them a versatile and reliable global supplier.

Bandit Industries

An American leader in hand-fed and whole-tree wood chippers, Bandit manufactures durable, application-specific chipper blades for their machines. Their blades are designed for high productivity in forestry, land clearing, and mulch production, with a focus on ease of maintenance and long service life. Bandit's reputation is built on robust construction and reliable performance in North American markets.

Morbark

A long-established manufacturer of heavy-duty wood processing equipment, Morbark produces rugged chipper blades built to handle the toughest jobs, including large-diameter logs and dirty wood. Their blades are known for exceptional durability and are often paired with their renowned drum and disc chipper designs, making them a staple in large-scale recycling, mulch, and biomass operations.

Vecoplan

The German engineering specialist offers high-precision shredder and granulator blades suitable for wood waste and plastic recycling. While known for plastics, their technology is applied to wood waste shredding for biomass fuel production. Vecoplan blades emphasize precision cutting, low energy consumption, and configurations that produce consistent particle sizes, appealing to European recycling markets.

Weima

Another German manufacturer, Weima produces robust shredding systems and corresponding blades for mixed material streams, including wood and plastics. Their blades are designed for high torque and slow-speed shredding, which is effective for processing bulky wood waste and composite materials. Weima's focus is on reliability and reducing wear in continuous industrial operations.

Frequently Asked Questions (FAQs)

Find expert answers to common questions about Wood Chipper Blades and PVC Pulverizer Knives for industrial recycling.