Shredder Blades Can Cut High Quality Alloy Parts in Batches

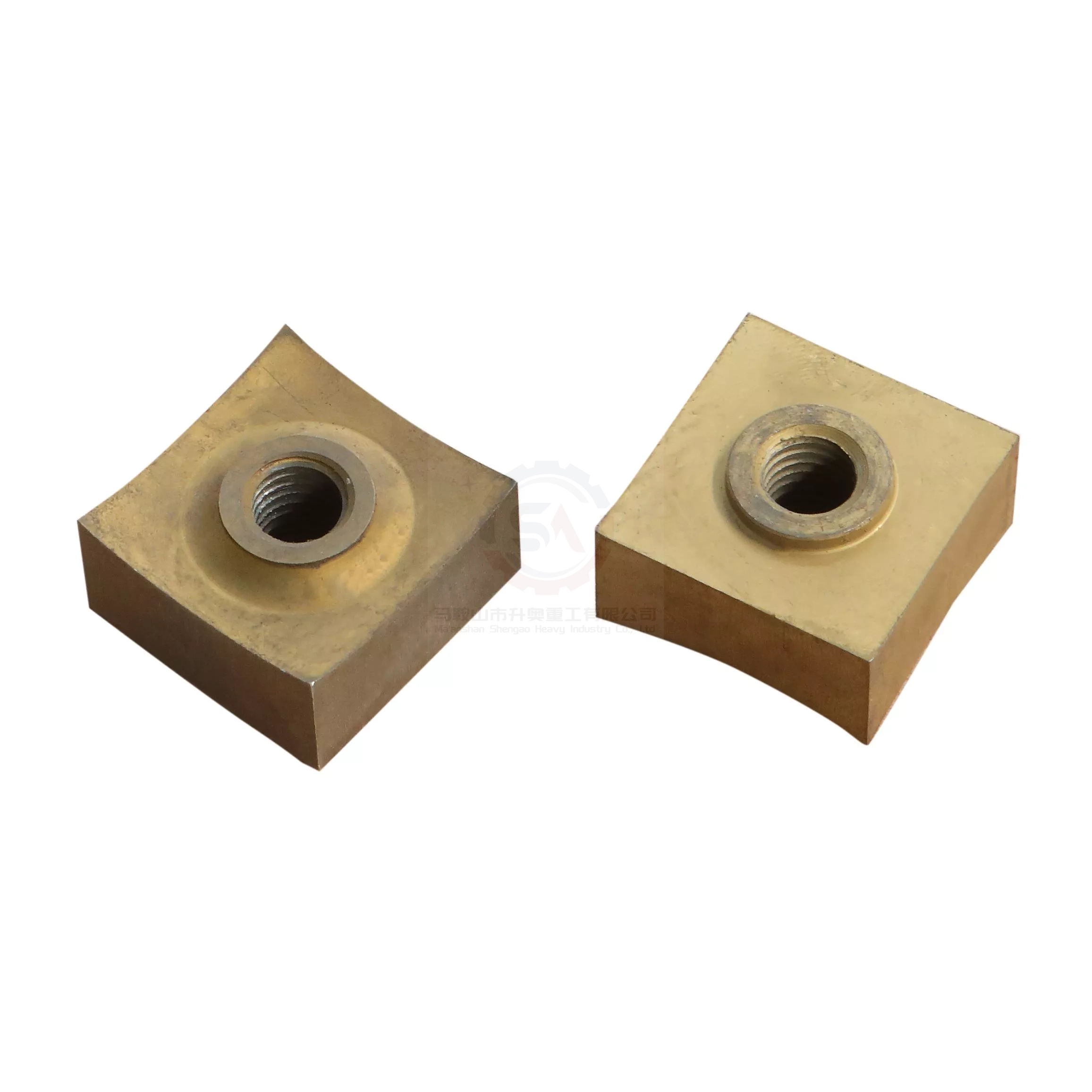

High-quality alloy shredder blades manufactured in batches. Designed for precision cutting, durability, and efficiency in industrial shredding applications. Ideal for bulk processing.

Get instant pricing and technical specifications for your project requirements

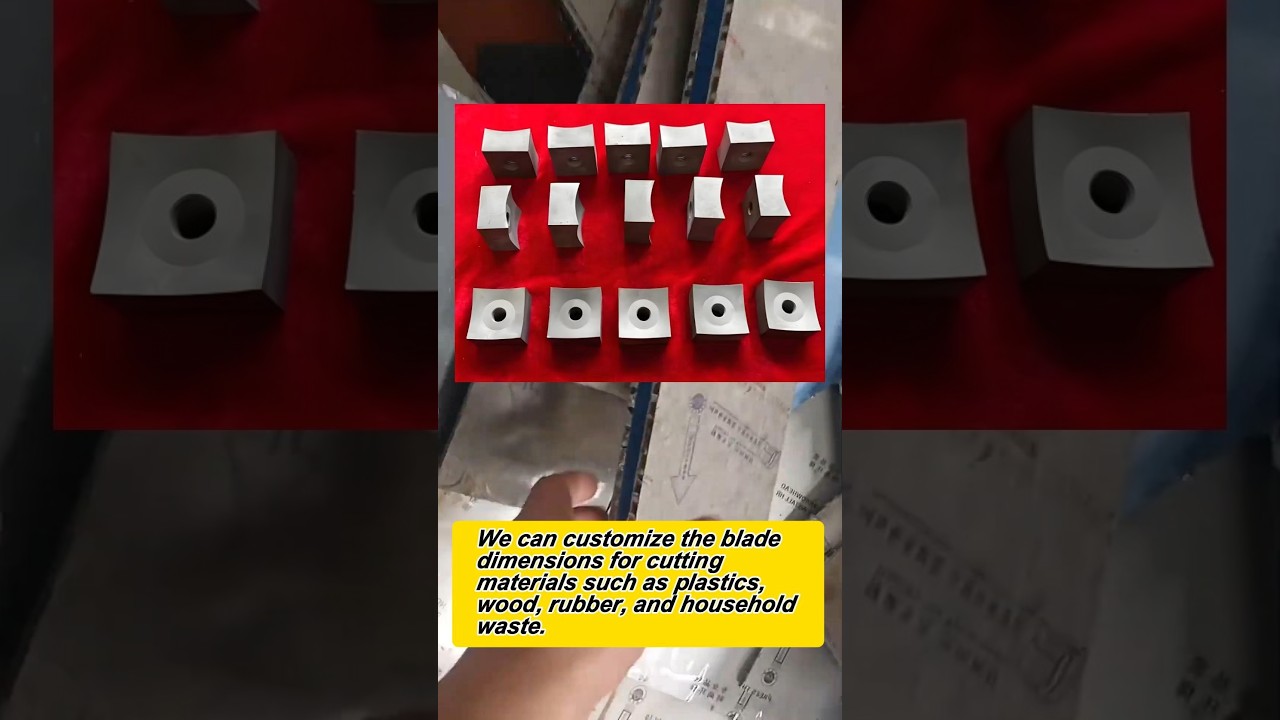

Product Video Demonstration

Product Specifications

| ShengAo Blade Scrap Metal Shear Blade Specifications | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Shredder Blades Can Cut High Quality Alloy Parts in Batches High-quality alloy shredder blades manufactured in batches. Designed for precision cutting, durability, and efficiency in industrial shredding applications. Ideal for bulk processing. | |||||||||||||

| Key Specifications | Product Name Scrap Metal Shear Blade Brand Name ShengAo Size (mm) 190/162/63/40 Purity 99.7% Place of Origin Anhui, China Main Application Scrap metal and recycling, Metal fabrication Package Solid wood box packaging | ||||||||||||

| Features & Advantages | Key Features High toughness Precision Eco-friendly Product Advantages Durable Efficient Customizable Keywords Hydraulic machine knife, Advanced heat treatment | ||||||||||||

| Quality Assurance | Quality Control Machinery test report: Provided Video outgoing-inspection: Provided Warranty & Core Components 6 Warranty: 6 Month P Core Components: Pressure Vessel | ||||||||||||

| Lead Time |

Lead time starts from order confirmation and deposit received. | ||||||||||||

| Customization Options | Option SIZE (As requested) Minimum Order 10 pieces Customization Fee -- | ||||||||||||

Raw Materials & Alloys

Crafted from premium materials for exceptional performance and durability

About Our Scrap Metal Shear Blades

Our high-quality alloy scrap metal shear blades, known as the Blade series, are engineered as the core cutting component for heavy-duty industrial scrap processing. Manufactured in precision batches, these blades are designed to handle the rigorous demands of cutting high-quality alloy parts consistently and efficiently. They are built to deliver maximum performance, durability, and reliability in the most challenging metal recycling and fabrication environments.

Premium Material & Construction

Our scrap metal shear blades are manufactured from high-purity, high-quality alloy steel with a purity level of 99.7%, ensuring exceptional material consistency and performance. Each blade undergoes advanced heat treatment processes to achieve an optimal balance of hardness and toughness, crucial for shearing through tough metals. We offer standardized sizes such as 190mm, 162mm, 63mm, and 40mm, with full customization available to meet specific hydraulic machine requirements. The precision grinding results in a clean, sharp edge ready for immediate industrial use.

Key Features & Benefits

Engineered for superior performance in metal shearing, our blades offer distinct advantages. The high toughness ensures they withstand extreme shock loads without chipping or breaking, while the exceptional precision in manufacturing guarantees clean cuts and extends the life of your hydraulic shear machine. Their eco-friendly design focuses on sustainability and reduced waste. Key benefits include outstanding durability for longer service intervals, high efficiency in batch processing of alloy parts, and full customizability to fit various machine models and applications, leading to lower operating costs and increased productivity.

Application Industries & Materials

These robust shear blades are purpose-built for demanding size reduction tasks in metal-intensive industries. They are highly effective in processing scrap metal of various grades, structural steel, demolition waste, automotive frames, and other high-quality alloy components. Industries that rely on our blades include scrap metal recycling yards, metal fabrication shops, demolition and decommissioning services, automotive salvage operations, and industrial waste processing facilities. Whether installed in stationary hydraulic shears or mobile processing units, these blades provide the reliable, high-force cutting required to transform bulky metal scrap into manageable, recyclable material.

Customization & Quality Assurance

We specialize in providing tailor-made shear blade solutions. All dimensions, including the specialized Blade profile, can be customized to fit your specific hydraulic shear model and material stream. Our commitment to quality is demonstrated through comprehensive documentation, including official machinery test reports and video outgoing-inspection for every order, providing verified performance data. Backed by a solid 6-month warranty, these blades represent a reliable investment. Securely packaged in solid wood box packaging to prevent damage during shipping, they arrive ready for installation and immediate integration into your metal processing workflow, ensuring minimal downtime.

Top 5 Industrial Scrap Metal Shear Blade Brands

Choosing high-quality shear blades is critical for efficient and safe metal processing. These manufacturers are recognized for their expertise in metallurgy, precision engineering, and proven performance in heavy-duty scrap shearing applications.

ShengAo (Good-Knife)

A leading manufacturer specializing in high-purity alloy scrap metal shear blades, including the Blade series. Their blades are crafted from 99.7% purity materials, undergo advanced heat treatment, and are available in standard sizes (190mm, 162mm, 63mm, 40mm) or fully customized. Known for high toughness, precision, and eco-friendly manufacturing, they offer comprehensive quality assurance with machinery test reports and video inspections. With a 6-month warranty, fast 10-20 day lead times, and solid wood box packaging, they are a reliable global supplier for metal recycling and fabrication.

Harris

An American pioneer in hydraulic scrap processing equipment, Harris manufactures robust shear blades for their extensive range of stationary and mobile shears. Their blades are engineered for maximum uptime and longevity in processing ferrous and non-ferrous scrap. Known for innovative designs that optimize cutting force and blade life, Harris is a trusted name in North American scrap yards and recycling centers.

Metso

A global leader in industrial machinery, Metso's Lindemann brand offers high-performance shear blades for metal recycling. Their blades are designed for use in high-capacity shredders and shears, focusing on wear resistance and reliable cutting of mixed and prepared scrap. Metso's engineering expertise ensures blades that contribute to high throughput and reduced operating costs in large-scale recycling operations worldwide.

SSI Shredding Systems

Known for their industrial shredders, SSI also provides durable shear blades for applications requiring precise cutting of metals and other tough materials. Their blades are built to withstand high shock loads and are integral to their shredding systems used in metal recycling, tire processing, and industrial waste reduction. SSI focuses on creating blades that maximize the efficiency and longevity of their equipment.

Arjes

A German manufacturer of slow-speed, high-torque shredders and shears, Arjes produces robust blades for processing demolition wood, metal, and mixed waste. Their shear blades are designed for efficiency in material reduction, with a focus on durability and low maintenance. Arjes equipment is popular in European recycling and demolition markets, where reliable performance is key.

Frequently Asked Questions (FAQs)

Find expert answers to the most common questions about Scrap Metal Shear Blades for industrial recycling and fabrication.