Unlock flawless corrugated paper production with the ultimate guide to choosing slitting blades—discover expert tips on blade types, materials.

Our industrial shredder blades deliver exceptional performance processing diverse materials in recycling and manufacturing operations. Engineered for durability and cutting efficiency, our blades maintain optimal sharpness through demanding operational cycles.

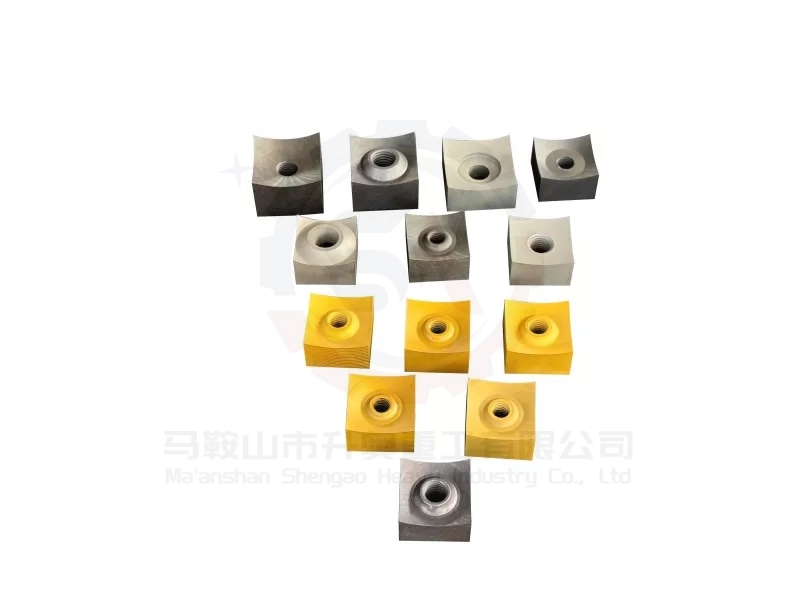

At our manufacturing facility, we produce reliable single-shaft and double-shaft shredder blades for universal industrial applications. Custom specifications including diameter, thickness, mounting holes and blade configurations are available. Material options include high-carbon steel, alloy steel, and specialized wear-resistant steels for extended service life in tough operating conditions.

Download our company brochures and product catalogs for detailed information

Comprehensive overview of our company, products, and manufacturing capabilities

Detailed specifications and production capabilities for our industrial blades

Support OEM/ODM services, producing items like slitting knives and cutting blades based on client drawings

Provides comprehensive data on blade specifications and complete dimensional data.

Premium cutting solutions for industrial applications

Our shredder blades are engineered for reliable performance and extended service life in various industrial recycling and manufacturing applications. Manufactured from premium materials including high-carbon steel, alloy steel, and specialized wear-resistant steels, our blades deliver efficient cutting performance across diverse materials. Our shredder blades feature optimized geometries and heat treatment processes that enhance durability and reduce maintenance requirements. With customizable dimensions, mounting configurations, and edge designs, we provide practical solutions for your specific shredding needs in single-shaft and double-shaft systems.

Send Inquiry Now

Our industrial shredder blades are widely used across various recycling and manufacturing sectors. From plastic recycling to wood processing, from municipal solid waste to industrial scrap materials, our blades deliver excellent cutting performance, durability, and cost-effectiveness. In packaging material recycling, manufacturing waste processing, and general industrial applications, our shredder blades ensure efficient and reliable size reduction. In the recycling industry, our blades handle various materials including plastics, rubber, textiles, and light metals. For manufacturing operations, we provide robust blade solutions for production scrap processing and material recovery applications.

Explore our specialized blade solutions designed for various industrial shredding applications

Our single-shaft shredder blades provide efficient cutting performance for various material processing applications.

Our double-shaft shredder blades offer superior cutting efficiency with interlocking design for enhanced material processing.

Our shredder blades incorporate universal design elements that enhance performance across various applications.

Find answers to common questions about our single-shaft and double-shaft shredder blades

Our industrial shredder blades are manufactured from high-quality materials to ensure durability and performance:

All materials undergo specialized heat treatment processes to achieve optimal hardness while maintaining toughness for various industrial applications.

Selecting the appropriate shredder blade type depends on several factors:

Our technical team can provide recommendations based on your specific material processing requirements.

Proper maintenance extends blade life and ensures optimal performance:

We provide detailed maintenance guidelines with every purchase and offer resharpening services.

Yes, we specialize in custom shredder blade manufacturing:

We can develop custom solutions with minimal order quantities starting from 5 units.

Our shredder blades serve diverse industrial applications:

Blade lifespan varies based on several factors:

With proper maintenance and appropriate material selection, our blades typically provide 6-18 months of service before requiring replacement or significant resharpening.

Watch for these indicators that your blades may need attention:

Regular inspection and preventive maintenance can help identify issues before they cause significant downtime.