Unlock flawless corrugated paper production with the ultimate guide to choosing slitting blades—discover expert tips on blade types, materials.

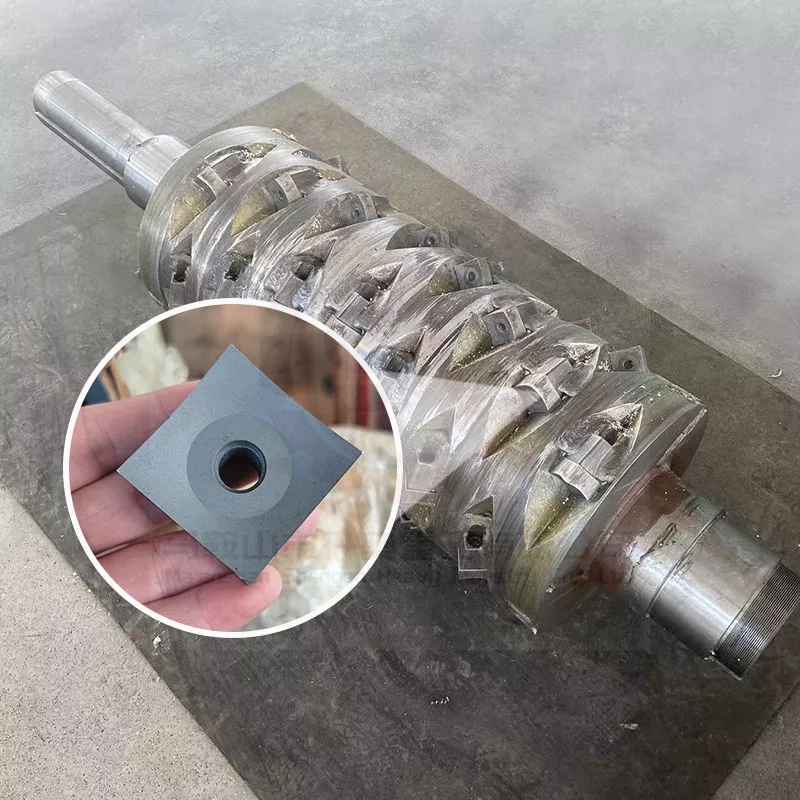

Shredder knives are the core cutting elements in granulating and size reduction systems, designed for processing reusable raw materials like PET, plastic, copper, aluminium, and rubber into granulate. As a leading industrial shredder blades manufacturer, we specialize in providing premium double shaft shredder blades and single shaft shredder blades for various recycling applications. All our shredder components are crafted from high-wear resistant materials including high-speed steel, CR12MOV, SKD-11, and D2 steel, achieving hardness levels between HRC 50-60 for optimal wear resistance and extended durability. We also manufacture precision shredder rotors and shafts to ensure complete system compatibility. Customization services are available based on your technical drawings or samples, guaranteeing perfect fit and performance for your specific granulators, cutting mills, and recycling equipment worldwide.

Download our company brochures and product catalogs for detailed information

Comprehensive overview of our company, products, and manufacturing capabilities

Detailed specifications and production capabilities for our industrial blades

Support OEM/ODM services, producing items like slitting knives and cutting blades based on client drawings

Provides comprehensive data on blade specifications and complete dimensional data.

Premium cutting solutions for industrial applications

Shredder knives serve as the essential cutting components in industrial size reduction systems, specifically engineered for processing reusable materials including PET, plastic, copper, aluminum, and rubber into uniform granules. As a specialized industrial shredder blades manufacturer, we focus exclusively on producing high-performance double shaft shredder blades, durable single shaft shredder blades, and precision-engineered shredder rotors. All our shredding components are manufactured from premium wear-resistant materials such as high-speed steel, CR12MOV, SKD-11, and D2 steel, achieving optimal hardness levels between HRC 50-60 to ensure exceptional wear resistance and operational longevity. We provide comprehensive customization services based on your technical specifications or samples, guaranteeing seamless compatibility with various granulators, cutting mills, and recycling equipment across global industrial applications.

Send Inquiry Now

Shredder blades are essential components across numerous recycling and material processing industries, delivering high performance in the reduction of various challenging materials. They are extensively employed in metal scrap recycling, plastic reprocessing, e-waste dismantling, tire shredding, wood processing, and municipal solid waste treatment. In automotive and battery recycling lines, our blades efficiently process metals and composites, while in plastic recycling plants, they handle PET bottles, films, pipes, and containers. For electronic waste and paper waste systems, the blades ensure precise and consistent particle size output. Custom-engineered shredder blades also support specialized applications in chemical, pharmaceutical, and Food Waste Shredding processing industries where hygiene and material integrity are critical. We provide tailored blade solutions to match specific machine types and operational requirements, enhancing productivity and wear life in continuous heavy-duty applications.

Explore our comprehensive range of shredding components designed for various size reduction challenges

Heavy-duty blades designed for primary reduction of tough materials in single and double-shaft shredders.

Precision cutting elements for granulating systems and fine size reduction applications.

Specialized cutting tools designed for specific material processing challenges.

Impact-based reduction tools for hammer mills and brutal size reduction applications.

The core driving components that deliver power and stability to shredding systems.

Find answers to common questions about our industrial shredder blades, knives, cutters, hammers, and rotors

Our shredder blades are manufactured from premium tool steels and alloys to ensure maximum durability and performance in demanding applications:

All materials undergo specialized heat treatment to achieve optimal hardness (typically HRC 56-58) while maintaining necessary toughness.

Selecting the appropriate shredder blade configuration depends on your specific application requirements:

Our technical team can provide specific recommendations based on your material composition and production goals.

Claw configuration significantly impacts cutting efficiency and material processing capabilities:

The optimal configuration depends on your specific material type and the desired output particle size.

Yes, we specialize in custom shredder blade manufacturing with extensive capabilities:

We can work from your technical drawings or samples to produce blades that match your exact requirements.

Proper maintenance significantly extends shredder blade service life:

We provide detailed maintenance guidelines specific to your blade type and application.

While often used interchangeably, knives and blades serve distinct functions in size reduction systems:

The specific terminology often varies by machine type and manufacturer.

Recognizing these signs can prevent costly downtime and damage to your equipment:

Regular monitoring of these indicators helps optimize replacement timing.

Yes, we offer comprehensive technical support services:

Our technical team is available to assist with both routine and complex operational challenges.

Our shredder components serve a wide range of industrial applications:

We also serve specialized applications in automotive, pharmaceutical, and food processing industries.

Lead times vary based on complexity and order quantity:

Expedited services are available for urgent requirements, and we maintain inventory of common blade types for quick shipment.