ShengAo: How Many Slitting Blade Types Do You Know?

ShengAo: How Many Slitting Blade Types Do You Know?

Table of Contents

- Introduction: The Critical Role of Precision Slitting Blades

- Circular Slitting Blades: The Workhorse of Modern Slitting

- Razor Slitting Blades: Unmatched Sharpness for Delicate Materials

- Shear (Scissor) Cut Blades: The Ultimate in Clean, Burr-Free Edges

- Crush Cut Blades: Simplicity and Economy for Specific Applications

- How to Choose the Right Slitting Blade: A Data-Driven Guide

- Maximizing Blade Life: Essential Maintenance and Best Practices

- ShengAo: Engineering Precision for Every Slitting Challenge

- Frequently Asked Questions (FAQ) About Slitting Blades

Introduction: The Critical Role of Precision Slitting Blades

In the vast landscape of industrial manufacturing, from transforming massive metal coils to precisely dividing fragile films, the slitting blade is an unsung hero. The efficiency, quality, and profitability of countless production lines hinge on the correct selection and application of these specialized tools. Yet, with various blade types available, how do you know which one is optimal for your specific material and desired finish? This comprehensive guide is designed to solve that exact problem. We will demystify the four primary slitting blade types—Circular, Razor, Shear, and Crush Cut—providing you with the knowledge to make informed decisions. You'll gain insights into their unique working principles, ideal applications across metals, polymers, papers, and composites, and the key factors that determine performance and longevity. By the end, you'll be equipped to optimize your slitting process, reduce waste, improve product quality, and ultimately enhance your bottom line. Whether you are a process engineer, a plant manager, or a procurement specialist, understanding the intricacies of slitting blade technology is the first step toward operational excellence.

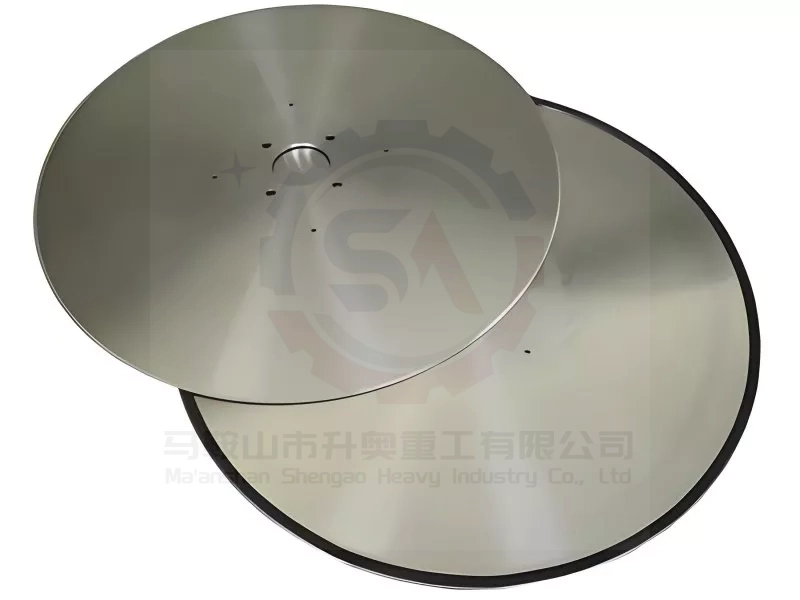

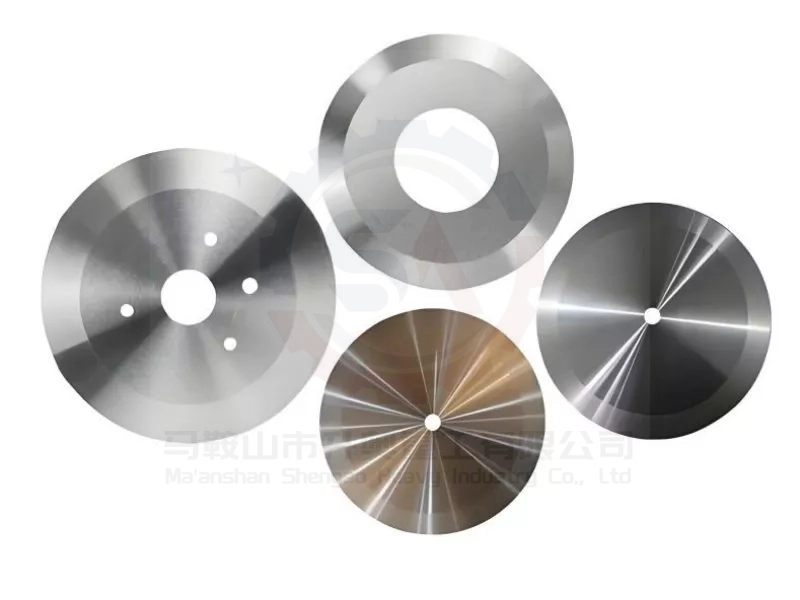

Circular Slitting Blades: The Workhorse of Modern Slitting

Circular slitting blades are the most common and versatile type used across heavy and medium-duty industries. Characterized by their solid, disk-like shape, they perform a "score cut" or "tangential cut" where the blade penetrates the material to a controlled depth, typically against a hardened steel anvil roll. This method is predominant in metal slitting but is also used for plastics, rubber, and paperboard.

How Do Circular Slitting Blades Work?

The process involves mounting multiple circular blades on arbors (shafts) in a specific "overlap" configuration. The top and bottom arbors rotate in sync, drawing the material through. The precise overlap and lateral positioning of the blades determine the slit width and edge quality. According to a 2022 report by the Fabricators & Manufacturers Association, over 65% of all flat-rolled metal slitting operations worldwide utilize some form of circular blade system due to its speed and adaptability.

Primary Applications and Material Suitability

- Metals: Steel (cold-rolled, hot-rolled, stainless), aluminum, copper, brass (Thickness: 0.1mm to 6.0mm+).

- Plastics & Films: Thicker plastic sheets, PVC, PET, polycarbonate.

- Others: Fiberglass, rubber sheets, gasket materials, paperboard.

Advantages and Disadvantages of Circular Blades

| Advantages | Disadvantages |

|---|---|

| High-speed operation suitable for volume production. | Can produce slight burr on the underside of metals. |

| Excellent for wide, heavy-gauge materials. | Higher initial setup and tooling cost. |

| Long blade life with proper hardening (e.g., Tungsten Carbide). | Requires precise alignment and maintenance. |

| Capable of producing very narrow strips. | Not ideal for extremely thin, fragile films. |

Razor Slitting Blades: Unmatched Sharpness for Delicate Materials

When the requirement is for an exceptionally clean cut on thin, sensitive materials without deformation, razor slitting blades are the go-to choice. These blades are essentially ultra-sharp, single-edged cutting tools that perform a "score cut" similar to circular blades but with a much finer edge geometry, often against a rubber or plastic roll.

The Mechanism Behind Razor Blade Slitting

The razor blade, held in a fixed position, lightly scores or slices through the material as it passes over a compliant (soft) counter roll. This roll gives way slightly, allowing for a clean penetration without crushing the material. A study published in the *Journal of Materials Processing Technology* noted that razor slitting generates up to 50% less lateral stress on film materials compared to shear cutting, minimizing edge distortion.

Ideal Use Cases: Where Razor Blades Excel

- Thin Films & Packaging: BOPP, CPP, PET, LDPE, shrink films (5µm to 250µm).

- Labels & Tapes: Pressure-sensitive adhesive tapes, label stocks.

- Foils & Laminates: Aluminum foil, metallized films, flexible laminates.

- Specialty Papers: Carbonless paper, photographic paper, lightweight non-wovens.

For operations demanding flawless edges on these sensitive substrates, partnering with a specialist like ShengAo can ensure you receive blades with the perfect edge keenness and coating to prevent adhesive buildup or premature wear.

Shear (Scissor) Cut Blades: The Ultimate in Clean, Burr-Free Edges

Shear cutting is the gold standard for achieving the highest quality edge, particularly in metal processing. It mimics the action of scissors, where two precisely angled circular blades—a top "male" blade and a bottom "female" blade—overlap and pass by each other to slice the material. This produces a clean, parallel cut with minimal burr.

Understanding the Shear Cutting Action

The key to shear cutting is the clearance angle between the two blades. This clearance must be meticulously set based on material type and thickness (typically 10-20% of material thickness). Proper clearance ensures a true shearing action rather than a tearing or breaking action. Industry data suggests that shear-cut edges can reduce post-processing (deburring) costs by up to 30% for precision components.

Applications Demanding Precision

- Precision Metals: High-grade stainless steel, spring steel, electrical steels (silicon steel), brass, and pre-painted metals.

- Critical Components: Parts for automotive, aerospace, and electronics where edge integrity is non-negotiable.

- Thicker Films & Composites: Where a razor blade might deflect, shear cut provides a straight edge.

Comparative Edge Quality: Shear vs. Score (Circular) Cut

| Edge Characteristic | Shear Cut | Score/Circular Cut |

|---|---|---|

| Burr Formation | Very Low to None | Low to Moderate (on underside) |

| Edge Squareness | Excellent | Good |

| Cross-Section Deformation | Minimal | Slight rounding/delamination possible |

| Typical Application Cost | Higher | Lower |

Crush Cut Blades: Simplicity and Economy for Specific Applications

Crush cutting, also known as "score cutting" in some contexts (not to be confused with circular score cutting), is the simplest mechanical slitting method. It involves forcing a sharp circular blade directly through the material and into a hardened anvil roll, literally crushing and fracturing it along the cut line.

How Crush Cutting Operates

There is no interplay between two blades. A single, often hardened steel, blade is set to a specific penetration depth into the anvil. This method is highly dependent on blade sharpness and anvil condition. While less sophisticated, it accounts for a significant portion of slitting in cost-sensitive or non-critical applications. Market analysis indicates crush cut systems represent approximately 40% of all installed slitting units for non-metallic materials, primarily due to lower machinery cost.

Suitable Materials and Common Pitfalls

- Best For: Paper, cardboard, textiles, non-woven fabrics (e.g., geotextiles), soft rubber, and some lower-grade plastics.

- Not Recommended For: Metals, laminated films, adhesive-coated materials (causes severe adhesive contamination), or any application requiring a high-quality edge.

Primary Challenge: Rapid blade and anvil wear, leading to frequent downtime for changeovers and inconsistent cut quality over time. For businesses using crush cutting for non-wovens or paper, upgrading to a higher-grade blade from a trusted Slitting Blade manufacturer can dramatically extend run times.

How to Choose the Right Slitting Blade: A Data-Driven Guide

Selecting the optimal blade is a multi-variable equation. Here is a step-by-step framework based on key industrial parameters:

- Material Analysis (The #1 Factor):

- Type: Metal, Polymer, Paper, Composite?

- Thickness/Gauge: This directly dictates blade geometry (bevel angle, thickness).

- Hardness/Tensile Strength: Determines required blade hardness (e.g., HRC 58-62 for steel, carbide for abrasive materials).

- Coatings/Surface: Pre-painted, laminated, or adhesive-backed materials need specialized blade coatings (PTFE, chromium nitride) to prevent buildup.

- Desired Edge Quality:

- Mission-Critical (Burr-Free): Shear Cut is almost always mandatory.

- Commercial Quality (Minimal Burr): High-precision Circular Blades.

- No Edge Spec (Fractured OK): Crush Cut or basic circular.

- Super Clean on Film: Razor Blades.

- Machine Parameters: Arbor size, max RPM, blade overlap capability, and holder type.

- Production Volume: High-volume runs justify investment in premium carbide blades for longer life.

Decision Matrix Table:

| Material Category | Thickness Range | Recommended Blade Type | Key Consideration |

|---|---|---|---|

| Stainless Steel Sheet | 0.3mm - 3.0mm | Shear Cut (Carbide Tipped) | Clearance setting; Blade hardness > HRC 60 |

| Aluminum Foil / Film | 0.006mm - 0.2mm | Razor Blade | Coated blades to prevent sticking; Soft counter roll durometer |

| Plastic Packaging Film | 0.02mm - 0.25mm | Razor or Shear Cut | Minimize edge stress; Anti-static options |

| Corrugated Cardboard | 1.5mm - 8.0mm | Crush Cut or Circular | Blade sharpness critical for clean cut; High wear |

| Non-Woven Fabric | 0.5mm - 5.0mm | Circular or Crush Cut | Blade geometry to prevent fiber pull |

Maximizing Blade Life: Essential Maintenance and Best Practices

Even the best slitting blade will underperform without proper care. Follow these evidence-based practices to extend service life:

- Proper Storage: Store blades individually in protective sleeves or holders in a dry, temperature-controlled environment. Vibration during transport can damage edges.

- Correct Installation & Alignment: Use torque wrenches for consistent clamping force. Misalignment is a leading cause of premature wear and poor cut quality. A study by the Association for Manufacturing Technology found that over 70% of premature blade failures are linked to improper setup or alignment.

- Regular Cleaning: Remove resin, adhesive, and material dust buildup after each run using appropriate, non-abrasive cleaners.

- Timely Sharpening/Replacement: Don't run blades until they are completely dull. Establish a schedule based on material footage. A dull blade requires more force, increases heat, and damages both the product and the machine.

- Lubrication (For Metal Slitting): Use the correct slitting oil or emulsion to reduce friction, heat, and burr formation.

ShengAo: Engineering Precision for Every Slitting Challenge

Navigating the complex world of slitting blades requires a partner with deep expertise and a commitment to quality. ShengAo stands as a leading force in the design and manufacture of precision slitting solutions. We understand that there is no one-size-fits-all answer. Our engineering team works closely with clients to analyze their specific materials, machine parameters, and quality goals to recommend or custom-engineer the perfect blade.

Whether you require ultra-hard tungsten carbide shear blades for high-strength steel, coated razor blades for sticky films, or robust circular blades for continuous non-woven production, ShengAo provides the reliability and cutting-edge technology your operation deserves. Our blades are synonymous with extended service life, consistent performance, and superior slit quality, helping you reduce total cost of ownership and boost productivity. Explore our comprehensive range of Slitting Blade solutions and discover how our precision can become your advantage.

Frequently Asked Questions (FAQ) About Slitting Blades

- Q: What is the main difference between slitting and shearing?

A: Slitting typically refers to cutting a wide coil or sheet into multiple narrower strips longitudinally. Shearing is a broader term that often means cutting off a piece from a sheet (trimming) or can refer to the specific shear-cutting slitting method that uses two angled blades. - Q: How often should I sharpen my circular slitting blades?

A: There's no fixed interval. It depends on material abrasiveness, production volume, and edge quality tolerance. Monitor burr height or edge finish. Many operations sharpen after 50-200 miles of material slit. Keeping a usage log is the best practice. - Q: Can I use a razor blade to slit thin metal?

A: Generally, no. Razor blades are for non-metallic, soft materials. Thin metal (like shim stock) is typically slit with precision circular or shear blades to maintain dimensional control and prevent dangerous blade shattering. - Q: What does "carbide-tipped" mean, and when is it necessary?

A: It means the cutting edge is made of ultra-hard tungsten carbide bonded to a tough steel body. It's necessary for slitting abrasive materials (e.g., fiberglass, certain composites, silicon steel), for very long runs, or when seeking maximum time between sharpening. Brands like ShengAo offer high-performance carbide solutions. - Q: What causes burr in metal slitting, and how can I minimize it?

A> Burr is caused by plastic deformation of the material during cutting. Minimize it by: using sharp blades, correct clearance (for shear cut), proper blade overlap (for score cut), adequate lubrication, and choosing the right blade hardness and geometry for the material. - Q: Are polymer/plastic blades ever used in industrial slitting?

A: Yes, but not as the primary cutting blade. They are often used as "separator discs" or "spacers" mounted between metal blades to prevent strip-to-strip abrasion and to help guide the slit material. - Q: How do I know if my shear cut clearance is correct?

A: The ideal clearance is a percentage of material thickness (e.g., 10-15% for mild steel). Signs of incorrect clearance: Too small causes excessive wear and force; too large causes large burr and edge deformation. Refer to blade supplier charts or conduct test cuts. - Q: What is "edge wash" in film slitting, and how is it prevented?

A> Edge wash is a wavy, distorted edge on thin film. It's caused by heat buildup from friction. Prevention methods: use sharper blades, ensure proper blade alignment, employ air-cooling on the blade, reduce line speed, and consider coated blades. - Q: My adhesive tape is gumming up the blades. What can I do?

A> This is a common issue. Solutions include switching to blades with a non-stick coating (e.g., PTFE/Polymer), applying a specialized release agent, using a blade heater to keep adhesive soft, or exploring a different slitting method (e.g., laser slitting for very gummy materials). - Q: Is laser slitting replacing mechanical blades?

A> For certain applications, yes (e.g., carbon fiber, complex composites, extremely sticky materials). However, for most high-volume metal, paper, and film slitting, mechanical blades remain far more cost-effective, faster, and require less maintenance, ensuring their dominance for the foreseeable future. - Q: Can ShengAo provide custom-designed blades for my unique machine?

A> Absolutely. A core strength of ShengAo is our ability to engineer custom solutions. We can work from your drawings or samples to produce blades with specific diameters, bore sizes, geometries, hardness, and coatings to fit proprietary or older machinery. - Q: What are the safety precautions when handling slitting blades?

A> Always wear cut-resistant gloves. Handle one blade at a time, using protective caps on the cutting edge. Never place blades loosely in a drawer. During installation/removal, ensure the machine is locked out (LOTO). Store blades securely to prevent edges from knocking together.