ShengAo High Speed Steel Single Shaft Shredder Blade, SKD11 Material, for Plastic & Wood Recycling

ShengAo SKD11 high-speed steel single shaft shredder blades, engineered for plastic & wood recycling. Premium material ensures durability and a sharp, long-lasting edge.

Get instant pricing and technical specifications for your project requirements

Product Video Demonstration

Product Specifications

| ShengAo Mechanical Plastic Crusher Blades - Product Specifications | |

|---|---|

Brand: ShengAo Type: Mechanical blade Keywords: Plastic Cutting Blade | |

| Core Specifications | Place of Origin: Anhui, China Usage: Plastic crushing Application: Plastic crushing Shaft Design: Single shaft shredder blade Advantage: Perfect High Cutting Efficiency Hardness: HRC 56-65 Flatness: ≤ 0.01 Core Components: PLC |

| Material & Dimensions | Available Materials

Size RangeFrom 30mm to 6m |

| Order Information | Minimum OrderMOQ: 1 Piece Customization OEM & ODM: Support |

| Quality Assurance | Machinery test report: Provided Video outgoing-inspection: Provided ✓ Warranty: 3 Months |

| Packaging & Delivery | PackagingWooden Case / Standard Export Packaging Standard Delivery Time30 days after deposit received |

| Production Lead Time | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| |||||||||||||||

| Technical Specifications Details | |

|---|---|

| Material Options | Alloy tool steel D2 1.2379 SKD11 High speed steel Customized materials |

| Hardness Range | 57 ~ 63 HRC (Hardness varies according to steel type and heat treatment) |

| Size Range & Tolerance | Available Sizes: From 30mm to 6m Customized sizes available Tolerance: Exceeds OEM specification Flatness: ≤ 0.01 |

| Application Materials | Plastic Rubber Metal Waste Recycling |

| OEM & Customization | Full OEM & ODM Services Available Custom sizes, materials, designs, and branding options |

Raw Materials & Alloys

Crafted from premium materials for exceptional performance and durability

About Our Single Shaft Shredder Blades

The single shaft shredder rotor blade and counter blade are the core components of any industrial shredder. As the heart of the machine, they are responsible for the primary size reduction of materials, transforming bulky waste into manageable fragments for easier handling, recycling, or disposal. Our precision-engineered blades are custom-made to exacting specifications, ensuring maximum cutting efficiency, durability, and perfect compatibility with your shredder model for superior processing performance.

Core Advantage: Every ShengAo blade is backed by video outgoing-inspection for verified quality and comes with a minimum order quantity (MOQ) of just 1 piece, making it accessible for both trial orders and large-scale procurement. We support full OEM & ODM services to meet your unique requirements.

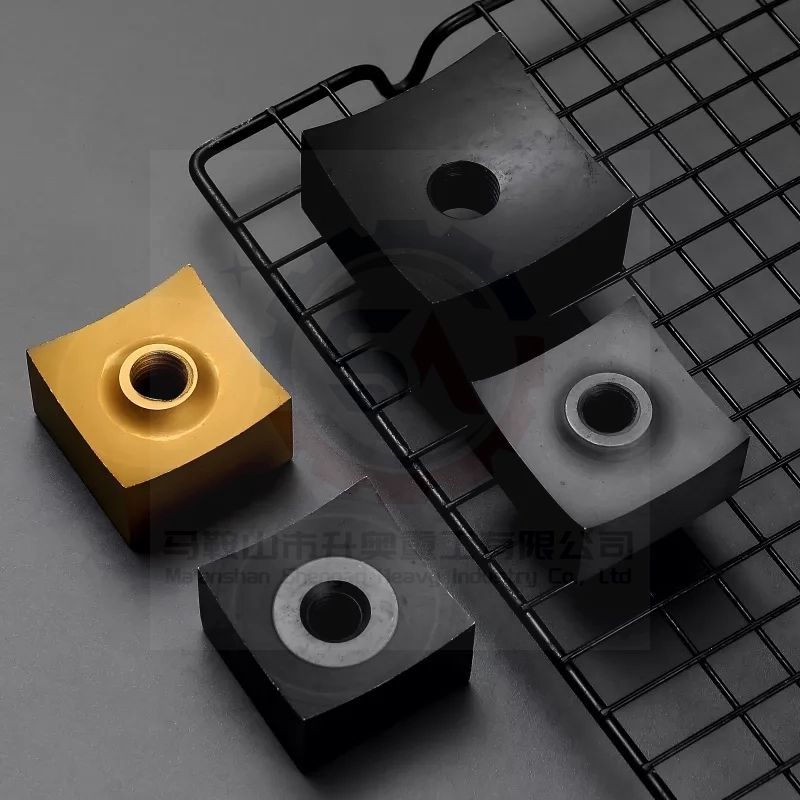

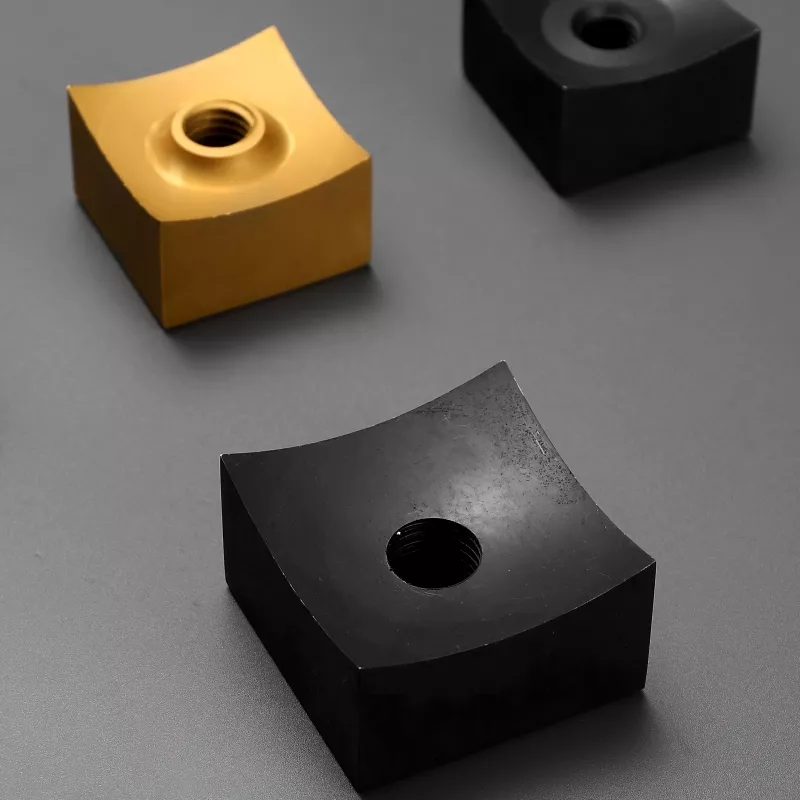

Premium Material & Construction

Our blades are primarily manufactured from premium-grade materials known for exceptional performance in demanding shredding applications. The star of our lineup is SKD11 (Alloy Tool Steel 1.2379), a high-carbon, high-chromium steel renowned for its outstanding wear resistance, toughness, and ability to hold a sharp edge.

Available Material Grades: SKD11 / D2 / 1.2379 High-Speed Steel (HSS) Custom Alloy Steel

We achieve a precise hardness of HRC 56-65 (typically HRC 57-63 for SKD11) through controlled heat treatment, optimizing the balance between hardness and toughness. Each blade undergoes high-precision CNC machining and grinding to achieve a flatness of 0.01 or less and a burr-free surface, guaranteeing smooth operation, minimal vibration, and consistent cutting performance batch after batch.

Key Features & Benefits

Designed for a long service life in the most challenging environments, ShengAo shredder blades deliver tangible operational benefits.

Superior Wear Resistance

SKD11 material significantly outlasts standard blades, dramatically reducing the frequency and cost of blade changes and machine downtime.

High Rigidity & Impact Resistance

Prevents bending and deformation under heavy load, and can handle unexpected hard contaminants in the material stream without catastrophic failure.

Perfect Cutting Efficiency

The precise geometry and sharp edge ensure clean cuts, lower energy consumption, and a higher, more consistent output volume.

Exceptional Flatness & Tolerance

Exceeds OEM specifications for perfect alignment on the rotor, leading to balanced operation, reduced wear on other components, and quieter running.

Application Industries & Materials

These versatile blades are engineered for a wide spectrum of industrial size-reduction tasks, excelling particularly in recycling and waste processing.

Primary Application: Plastic Crushing - Ideal for shredding hard plastics, lumps, purgings, PET bottles, PE/PP films, and engineering plastics.

Other Key Materials: Wood, rubber, textiles, non-ferrous metals, and general municipal or industrial waste. Industries such as plastic recycling, waste management, manufacturing, and e-waste processing rely on the reliability and efficiency of ShengAo single shaft shredder blades to maintain productivity and reduce operational costs.

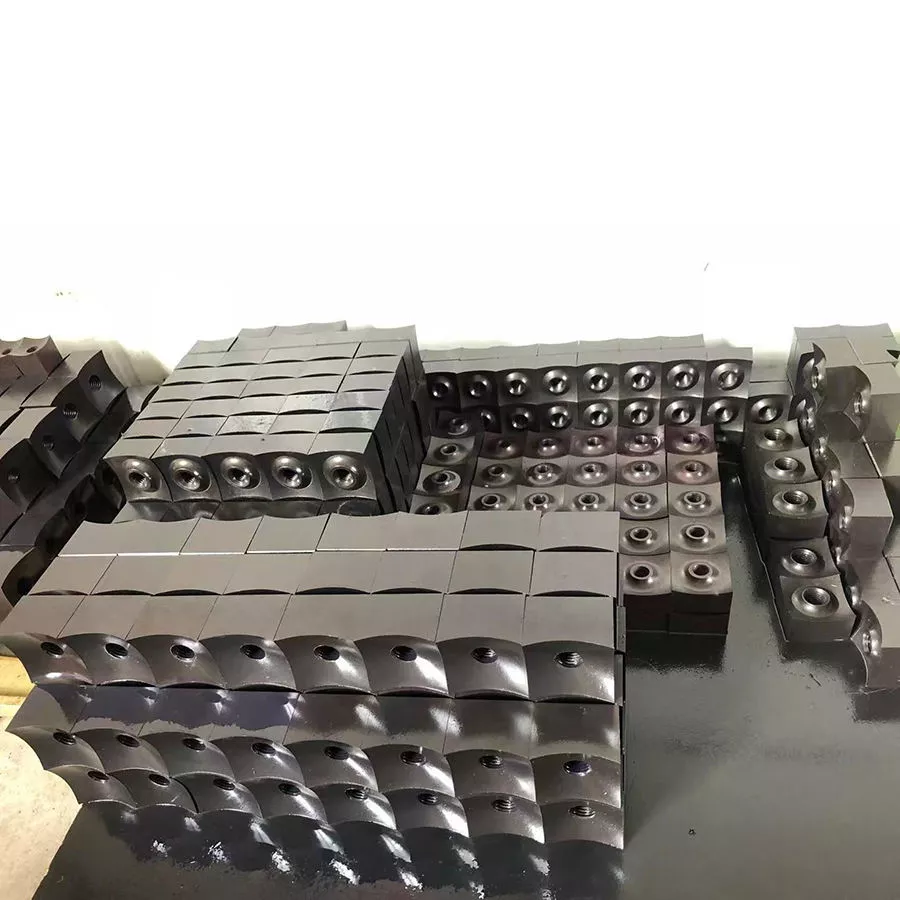

Customization & Quality Assurance

We specialize in providing complete tailor-made blade solutions. From dimensions (we offer sizes from 30mm to 6 meters or fully customized) to specific material grades and hardness profiles, we adapt to your exact single shaft shredder model and material stream.

Our commitment to quality is unwavering and transparent. Beyond standard material certifications, we provide video outgoing-inspection for visual verification of each order. Every batch is securely packed in standard export wooden cases to ensure perfect condition upon arrival at your facility, ready for immediate installation and peak performance.

Top 5 High-Speed Steel Single Shaft Shredder Blade Brands

Selecting the right blade brand is critical for machine uptime and processing cost. Here are five leading manufacturers known for quality in the shredder blade market.

1. ShengAo

Origin: Anhui, China

Strength: Exceptional value leader offering premium SKD11/HSS blades with verified quality (video inspection), full customization (OEM/ODM), and a low MOQ of 1 piece. Perfect balance of performance, transparency, and cost-effectiveness for plastic and wood recycling.

2. ForTech (Europe)

Renowned for high-precision blades for European shredder brands, utilizing advanced metallurgy and coatings for extreme wear applications in metal and e-waste recycling.

3. SSI Shredding Systems

A global OEM that also supplies high-quality replacement blades for their systems and others, known for robust engineering and application-specific designs.

4. WEIMA

Original equipment manufacturer providing genuine blades with guaranteed compatibility for WEIMA shredders, focusing on durability and optimized cutting geometry.

5. Genox

Specializes in blades for their own range of shredders, with a strong focus on technical innovation and blades designed for high-throughput plastic recycling operations.

Frequently Asked Questions (FAQ)

Find quick answers to common queries about single shaft shredder blades.