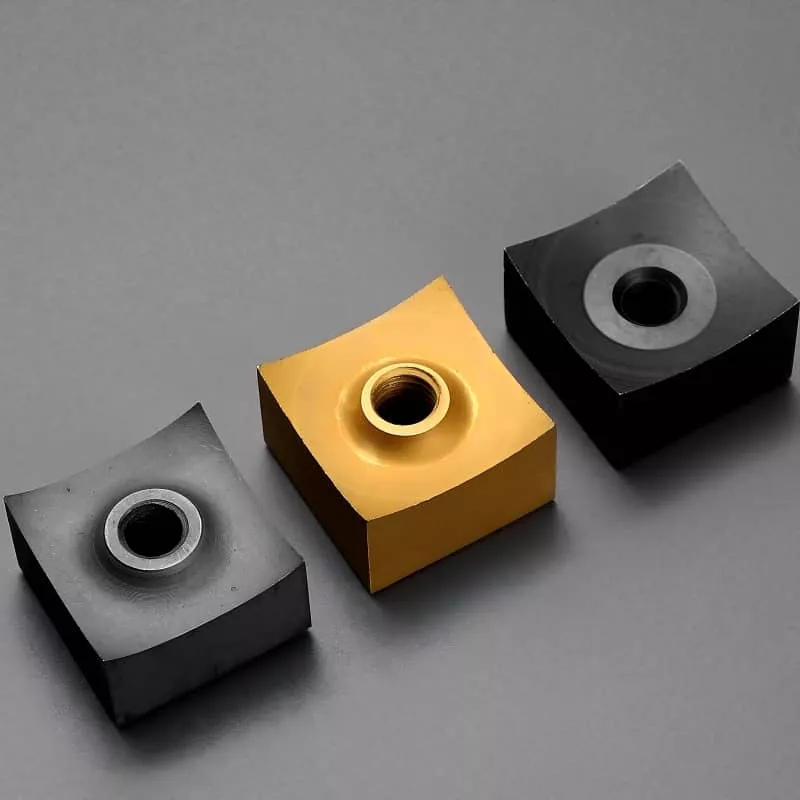

ShengAo High Quality Single Shaft Shredder Rotary Blades Plastic & Rubber Crusher Stationary Blade Good For Crushing Shredding

ShengAo single shaft shredder rotary blades for plastic & rubber crushing. High-quality stationary blades ensure efficient shredding and material processing.

Get instant pricing and technical specifications for your project requirements

Product Video Demonstration

Product Specifications

| ShengAo High Quality Single Shaft Shredder Rotary Blades | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

ShengAo Single Shaft Shredder Rotary Blades for Plastic & Rubber Crushing High-quality stationary blades ensure efficient shredding and material processing for plastic and rubber granulator crushers. Designed with perfect high cutting efficiency. | ||||||||||||||||

| Product Specifications | Brand Name ShengAo Type Mechanical blade Place of Origin Anhui, China Usage Plastic crushing Shaft Design Single shaft shredder blade Application Plastic crushing Hardness (HRC) 56-65 Package Wooden Case Flatness 0.01 or less MOQ 1 Piece Keywords Plastic Cutting Blade | |||||||||||||||

| Quality Assurance | Quality Control Machinery test report: Provided Video outgoing-inspection: Provided Warranty & Core Components 6 Warranty: 6 Month C Core Components: Rubber and tyre granulator crusher blade plastic | |||||||||||||||

| Lead Time | Quantity-Based Lead Time

| |||||||||||||||

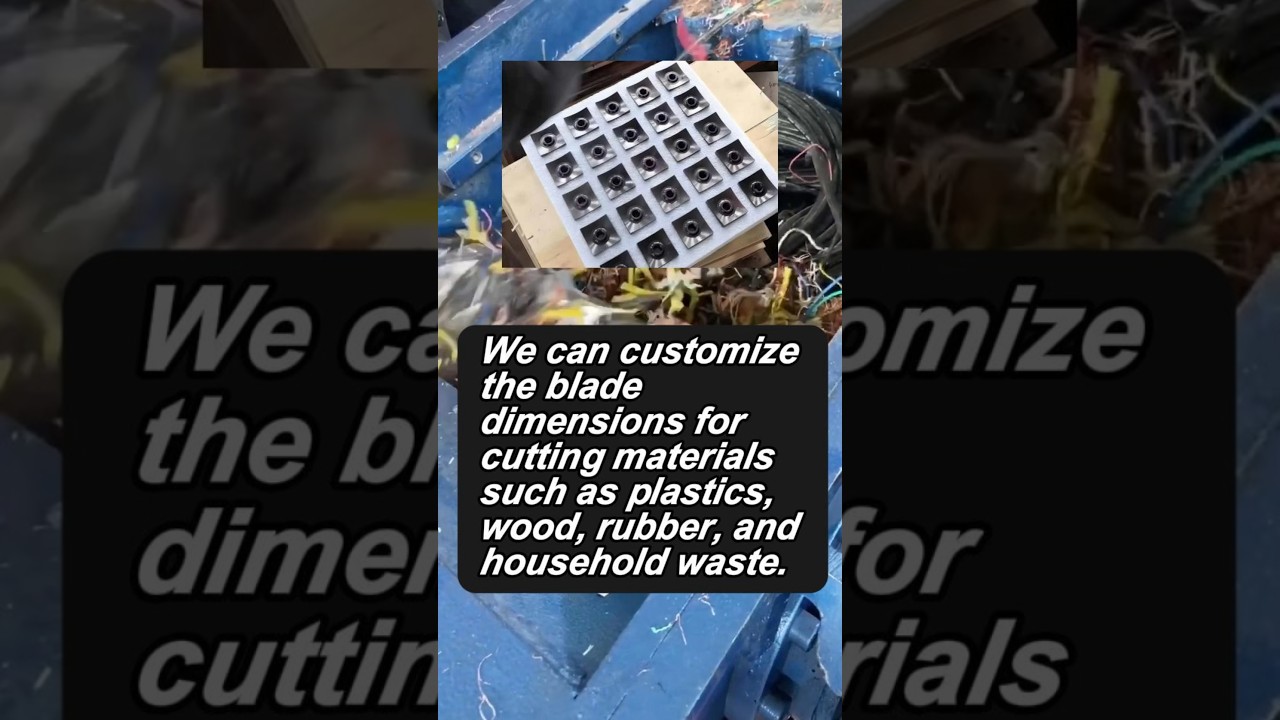

| Customization Options | OEM & ODM Service Support Available Options

| |||||||||||||||

Raw Materials & Alloys

Crafted from premium materials for exceptional performance and durability

About Our Single Shaft Shredder Rotary Blades

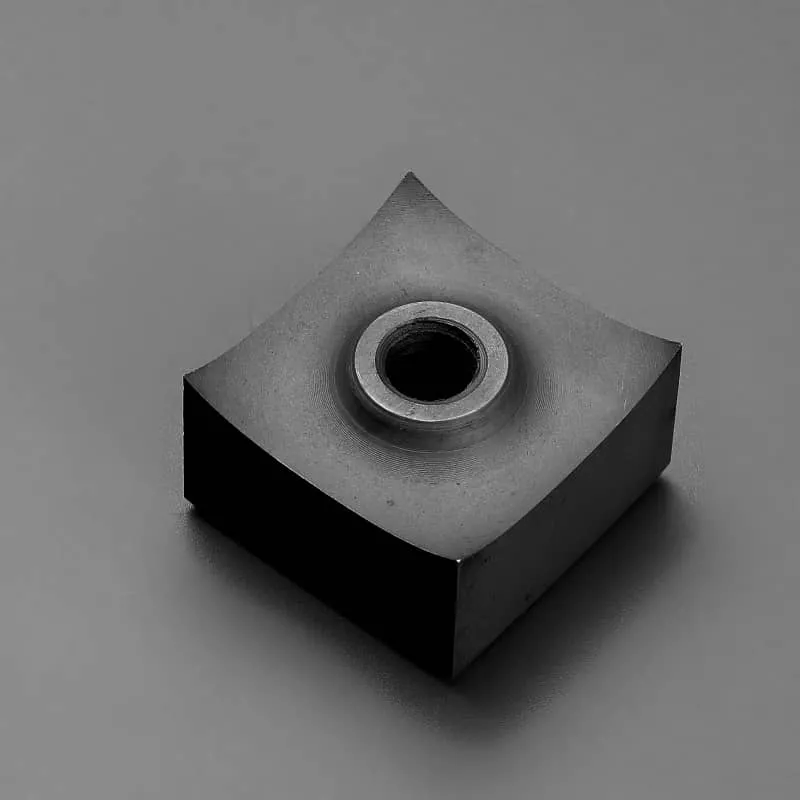

The single shaft shredder rotor blade and counter blade are the core components of a shredder, comprising a square-shaped moving knife that rotates against a stationary bed knife. Engineered for high cutting efficiency in plastic and rubber granulator crushers, these blades are used across various industries to reduce material size for easier handling, recycling, or further processing. Custom-designed for reliability and durability, they are the critical interface between raw waste and valuable regrind in your recycling line.

Premium Material & Construction

Our single shaft shredder blades are manufactured from premium alloy tool steels, heat-treated to achieve an exceptional hardness range of HRC 56-65. This superior hardness provides exceptional wear resistance and toughness, ensuring high rigidity and impact resistance necessary for shredding challenging plastic lumps, films, and rubber materials. Each blade is precision machined to an outstanding flatness of 0.01 or less, guaranteeing a high-precision, burr-free surface for smooth operation, minimal vibration, and consistent cutting performance in demanding industrial environments.

Key Features & Operational Benefits

Designed for a long service life in continuous plastic and rubber crushing operations, these blades offer significant operational advantages. The high hardness (HRC 56-65) provides excellent wear resistance, significantly extending the interval between sharpening or replacement and reducing operational downtime. The precise construction and high flatness ensure stable and efficient shredding output, consistent particle size, and reduced energy consumption. This translates directly into lower cost per ton processed, higher machine uptime, and improved overall efficiency for your recycling operation.

Application Industries & Materials

These high-performance single shaft blades are specifically engineered for plastic and rubber granulator crushers. They excel in processing a wide range of materials, including plastic lumps, purgings, films, sheets, bottles, containers, PVC profiles, rubber tires, and various post-industrial plastic waste. The primary application is in plastic crushing and rubber recycling. Industries that heavily rely on these durable blades include plastic recycling facilities, tire recycling plants, injection molding and blow molding operations with in-house scrap recovery, and waste management companies.

Customization & Comprehensive Quality Assurance

We specialize in providing tailor-made single shaft blade solutions through comprehensive OEM and ODM services. From specific dimensions to material grade selection, we can customize blades to fit your exact shredder model and material stream. Our commitment to quality is robust, demonstrated through provided video outgoing-inspection and official machinery test reports. Every blade is backed by a solid 6-month warranty and is securely packed in wooden cases to ensure perfect condition upon arrival, ready for immediate installation and reliable operation in your facility.

Top 5 Single Shaft Shredder Rotary Blade Manufacturers

Selecting the right manufacturer for single shaft shredder blades is critical for achieving high cutting efficiency and low operating costs in plastic and rubber recycling. These companies lead in providing durable, precise, and application-specific blade solutions.

ShengAo

A specialized manufacturer of high-quality single shaft shredder rotary and stationary blades, focusing on plastic and rubber crushing applications. Their blades are heat-treated to a high hardness of HRC 56-65 and machined to an exceptional flatness of ≤0.01 for precise, efficient cutting. Key advantages include a strong focus on the plastic granulator market, comprehensive OEM/ODM support, a competitive 6-month warranty, and robust quality control with video inspection and test reports. They offer practical lead times (7 days for 1-50 pcs) and secure wooden case packaging.

Vecoplan

A global German leader in shredding technology, Vecoplan manufactures robust single shaft shredders and their corresponding high-wear blades. Their blades are engineered for longevity in processing mixed and contaminated plastic streams, wood waste, and paper. Known for innovative cutter geometries and durable material selection, they provide strong application engineering support to match blade design to specific material challenges, ensuring optimal throughput and particle size in demanding recycling operations.

WEIMA

A prominent German manufacturer offering a range of single shaft shredders and replacement blades designed for their own machinery. WEIMA focuses on energy-efficient and reliable size reduction. Their blades are built for processing various plastics, wood, and industrial waste, with designs that emphasize low maintenance, ease of replacement, and consistent performance to support high-volume processing in recycling and manufacturing settings.

Forrec

An Italian specialist in industrial shredding systems. Forrec produces heavy-duty single shaft shredders and blades built for high-volume processing of challenging materials like mixed plastics, rubber, and municipal solid waste. Their blade designs prioritize maximum uptime, durability, and the ability to handle large, bulky feedstocks, making them suitable for large-scale recycling and waste management facilities.

Zerma

A German manufacturer of size reduction machinery, Zerma offers single shaft shredders and robust blades primarily for the plastics recycling industry. Their solutions are tailored for processing plastic lumps, pipes, profiles, and purgings. Zerma blades are known for their solid engineering, reliability, and are designed to integrate seamlessly with their granulators and recycling systems, providing a holistic approach to plastic waste processing.

Frequently Asked Questions (FAQs)

Find expert answers to common questions about ShengAo Single Shaft Shredder Blades for plastic and rubber crushing applications.