ShengAo Double Shaft Shredder Blades for Tire, Metal, Solid Waste

ShengAo Double Shaft Shredder Blades for Tire, Metal, Solid Waste

Table of Contents

- ShengAo Shredder Blades: Mastering Single & Double Shaft Technology

- ShengAo Double Shaft Shredder Blades: Powering Through the Toughest Materials

- ShengAo Single Shaft Shredder Blades: Our Core Expertise

- The Science of Cutting: High-Grade Alloys in ShengAo Blades

- Universal Compatibility: ShengAo Blades for Global Shredder Brands

- Why Choose ShengAo Industrial Shredder Blades?

- Conclusion: Partner with ShengAo for Unmatched Shredding Performance

ShengAo Shredder Blades: Mastering Single & Double Shaft Technology

In the demanding world of size reduction and recycling, the heart of any shredding system is its blade. The efficiency, durability, and cost-effectiveness of your entire operation hinge on the quality of these critical components. At ShengAo, we specialize in engineering the pinnacle of shredding performance. Our focus is singular and profound: we produce premium single shaft shredder blades and robust double shaft shredder blades. This dedicated expertise allows us to perfect our craft, delivering blades that consistently outperform and outlast the competition. Whether you are processing tires, metal drums, solid waste, plastics, or wood, ShengAo provides the cutting-edge solution you need to maximize uptime and profitability.

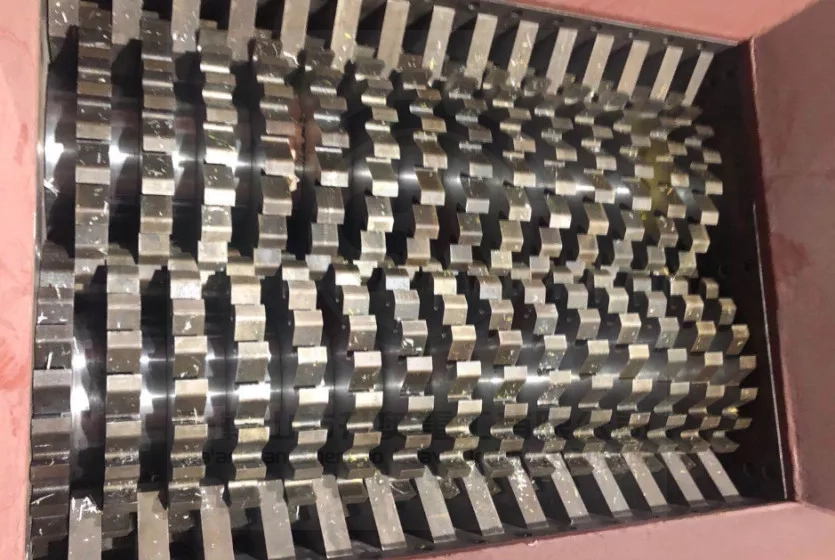

ShengAo Double Shaft Shredder Blades: Powering Through the Toughest Materials

Our ShengAo Double Shaft Shredder Blades are the epitome of heavy-duty engineering. Designed for high-torque, low-speed applications, they excel in the primary reduction of the most challenging materials. The dual-shaft mechanism, with its intermeshing blades, creates a powerful shearing and tearing action that can rip apart whole tires, crush metal drums into manageable chips, and break down bulky solid waste with relentless efficiency. These blades are built not just to cut, but to dominate. They are the first line of defense in any recycling line, tasked with transforming large, unwieldy objects into a uniform, conveyable feedstock. When your operation demands brute force and unwavering reliability, our double shaft blades are the undisputed choice.

Key Applications:

- Tire Shredding: Efficiently reduces whole car and truck tires into rubber chips.

- Metal Shredding: Handles white goods, drums, and light structural metal.

- Solid Waste: Processes municipal and industrial solid waste (MSW & ISW).

- E-Waste: Breaks down computers, appliances, and other electronic waste.

ShengAo Single Shaft Shredder Blades: Our Core Expertise

While we excel in dual-shaft technology, our true competitive advantage lies in our single shaft shredder blades. This is where our engineering prowess truly shines. The single shaft shredder blade system is renowned for its powerful, direct-drive cutting action, making it ideal for a diverse range of materials, from plastics and wood to paper and non-ferrous metals. Our single shaft blades often feature a hook or V-shape design that aggressively grabs and pulls material into the cutting chamber, ensuring consistent feeding and a clean, controlled cut. The advantage of our single shaft design is its exceptional versatility and efficiency in secondary shredding or for processing specific material streams where a finer output size is required. We have invested countless hours in R&D to perfect the geometry, heat treatment, and material selection for our single shaft blades, making them the most reliable and cost-effective option on the market.

Key Applications:

- Plastic Recycling: Perfect for size reduction of lumps, purgings, pipes, and profiles.

- Wood Waste: Efficiently processes pallets, construction waste, and tree limbs.

- Paper & Cardboard: Reduces waste volume for recycling and baling.

- Non-Ferrous Metals: Shreds aluminum, copper, and other soft metals.

The Science of Cutting: High-Grade Alloys in ShengAo Blades

The performance of any industrial shredder blade is fundamentally determined by its material composition. At ShengAo, we refuse to compromise. We utilize a range of high-grade, wear-resistant alloys to ensure our blades meet the specific demands of your application. Our metallurgists select the optimal steel to provide the perfect balance of hardness, toughness, and wear resistance.

- D2 Tool Steel: Known for its high carbon and high chromium content, D2 offers excellent wear resistance and high compressive strength. It is ideal for plastic shredder blades and applications involving abrasive materials.

- H13 Hot-Work Steel: H13 maintains its hardness and strength at elevated temperatures, making it perfect for prolonged, high-stress shredding operations. It's a top choice for demanding metal shredder blades.

- 9CrSi Alloy Steel: This steel provides a superb combination of high hardness, good toughness, and excellent fatigue resistance. It is a versatile and cost-effective option for many wood shredder blades and general-purpose shredding tasks.

Every batch of steel is rigorously inspected, and every blade undergoes a precise heat treatment process to achieve its optimal microstructure and hardness (typically HRC 58-62). This scientific approach to manufacturing guarantees that every ShengAo blade delivers maximum service life and a lower cost-per-ton, making it the smartest choice for your business. For a deeper dive, explore our guide to shredder blade materials.

Universal Compatibility: ShengAo Blades for Global Shredder Brands

A common challenge in the industry is finding high-quality, reliable replacement blades for major shredder brands. ShengAo solves this problem. We pride ourselves on our ability to engineer and manufacture custom blades that are direct replacements for a wide array of international shredder manufacturers. Our technical team can reverse-engineer and produce blades to the exact specifications of your machine, ensuring a perfect fit and optimal performance. Below is a non-exhaustive list of brands we regularly provide blades for.

Metso

We produce high-performance replacement blades for various Metso shredders used in recycling and mining. Our blades are engineered to match or exceed the durability and cutting efficiency of the original parts, ensuring your Metso equipment maintains its high productivity.

Vecoplan

As a leader in shredding technology, Vecoplan machines demand precision. Our custom-engineered single and double shaft blades for Vecoplan shredders are meticulously crafted to deliver the same high-quality shredding performance, providing a reliable and cost-effective alternative to OEM parts.

UNTHA

UNTHA is synonymous with precision and reliability. Our shredder knife solutions for UNTHA machines are manufactured with the same attention to detail, ensuring perfect dimensional accuracy and material integrity for seamless integration and long-lasting performance.

WEIMA

For WEIMA's extensive range of size reduction equipment, we offer a comprehensive selection of single shaft shredder blades. Whether it's for plastic, wood, or paper, our blades help maintain WEIMA's renowned efficiency and low operating costs.

Genox Recycling

We supply durable and efficient blades for Genox shredders and granulators. Our expertise in plastic recycling blades makes us an ideal partner for Genox users in the plastic recycling industry, helping to achieve clean and consistent granulate quality.

Harden Machinery

ShengAo provides robust replacement blades for Harden Machinery's shredders. Our custom solutions ensure that your Harden shredder continues to perform reliably in demanding applications like solid waste and industrial scrap processing.

GEP ECOTECH

For the comprehensive range of GEP ECOTECH shredders, we offer precisely manufactured blades that deliver exceptional performance and longevity. Our blades are a smart choice for maintaining the productivity of your GEP smart shredding systems.

Maxin India Machinery

We support the growing recycling market in India with high-quality replacement blades for Maxin shredders. Our products help Maxin equipment owners reduce downtime and operational costs.

Hammel

Hammel shredders are built for power and durability. Our replacement blades are engineered to withstand the extreme forces generated by Hammel machines when processing tires, wood, and mixed waste, ensuring you get the most out of your powerful equipment.

Arjes

For Arjes slow-speed, high-torque shredders, we provide robust blades designed for maximum wear resistance and impact strength. Our blades are perfect for handling construction debris, green waste, and other tough materials that Arjes machines are known for.

Stiler

We manufacture custom blades for Stiler shredders, ensuring a perfect fit and reliable performance. Our technical drawings and quality control process guarantee that every blade meets the original specifications.

Olnova

ShengAo offers replacement blade solutions for Olnova shredding systems. Our focus on quality and durability ensures that your Olnova machine continues to operate at peak efficiency with minimal maintenance interruptions.

Why Choose ShengAo Industrial Shredder Blades?

Choosing ShengAo is more than just buying a blade; it's investing in a partnership dedicated to your success. Our commitment to excellence is evident in every aspect of our business.

- Unmatched Expertise: We focus exclusively on single and double shaft shredder blades, making us specialists, not generalists.

- Superior Materials: We use only certified, high-grade alloys like D2, H13, and 9CrSi.

- Precision Engineering: Our blades are manufactured to exacting tolerances for a perfect fit and optimal performance.

- Customization: We provide fully custom blade solutions for virtually any shredder brand and application.

- Proven Durability: Our advanced heat treatment processes yield a high hardness blade with exceptional wear life.

- Global Support: We serve clients worldwide with reliable logistics and technical support.

Conclusion: Partner with ShengAo for Unmatched Shredding Performance

In the relentless environment of industrial shredding, downtime is the enemy, and blade failure is its primary cause. Don't let substandard blades compromise your operation's efficiency and profitability. By choosing ShengAo, you are selecting a partner who understands the critical nature of your work. Our dedicated focus on single and double shaft technology, combined with our use of premium materials and precision manufacturing, results in shredder blades for sale that are built to last and perform from the first cut to the last.

Ready to experience the ShengAo difference? Explore our full range of products and discover how our blades can transform your shredding operation. For a limited time, take advantage of our Black Friday promotion on our most popular Industrial Shredder Blades. Our global customers can also learn more in their native language: 日本のお客様は産業用シュレッダーブレードをご覧ください。Наши русскоязычные клиенты могут ознакомиться с информацией на странице Промышленные ножи для шредеров.

Contact us today for a custom quote and let us help you achieve new levels of shredding productivity and cost savings.