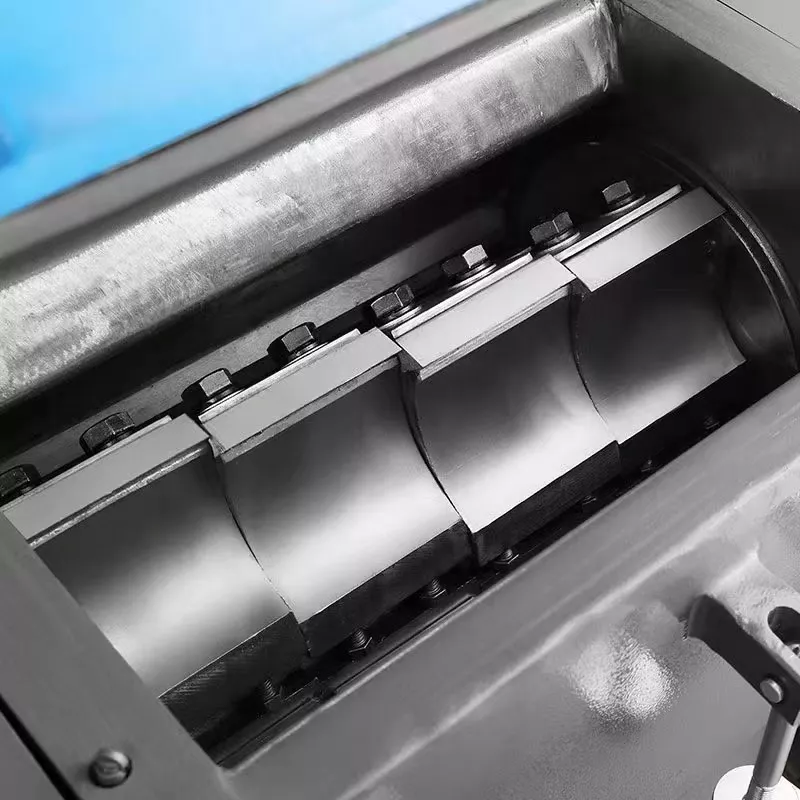

Rotor and Stationary Shredder Blades for Crushing Plastic Rubber Tyre

Robust rotor & stationary shredder blades for crushing plastic, rubber, and tires. Built for heavy-duty industrial recycling. Ensures consistent performance and high wear resistance.

Get instant pricing and technical specifications for your project requirements

Product Video Demonstration

Product Specifications

| ShengAo Shredder Blades - Plastic, Rubber & Tire Crusher Blades | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Rotor and Stationary Shredder Blades for Crushing Plastic, Rubber and Tyre Robust rotor & stationary shredder blades for crushing plastic, rubber, and tires. Built for heavy-duty industrial recycling. Ensures consistent performance and high wear resistance. | |||||||||||||

| Key Attributes | Brand Name ShengAo Type Shredder Blade Place of Origin Anhui, China Feature High Speed, Straight Smooth Edge Spare Parts Type Blade Application Manufacturing Plant Usage Crusher Machine Knife Packing Durable ply-wooden box packing Tolerance Exceed OEM Specification OEM Service Support | ||||||||||||

| Specifications & Material | Material Options D2, M2, 52100 or customized Size Customized | ||||||||||||

| Quality Assurance | Quality Control Machinery test report: Provided Video outgoing-inspection: Provided Warranty & Core Components 3 Warranty: 3 Months ✓ Core Components: Blade | ||||||||||||

| Lead Time |

| ||||||||||||

| Customization Options |

| ||||||||||||

Raw Materials & Alloys

Crafted from premium materials for exceptional performance and durability

About Our Rotor & Stationary Shredder Blades

Our rotor and stationary shredder blades form the essential cutting system at the heart of industrial shredding machines. These robust components work in tandem to efficiently reduce the size of challenging materials like plastic, rubber, and tires for easier handling, recycling, or disposal. Engineered for maximum performance and durability in heavy-duty applications, our custom-made blades ensure consistent cutting action and reliable operation in demanding recycling environments.

Premium Material & Precision Construction

We manufacture our shredder blades from high-performance tool steels including D2, M2, and 52100, with options for customized materials to meet specific operational requirements. D2 tool steel offers exceptional wear resistance ideal for abrasive materials, M2 high-speed steel provides excellent hot hardness for continuous operation, and 52100 bearing steel delivers superior toughness for impact resistance. Each blade features a straight smooth edge with high-precision machining that exceeds OEM specifications, ensuring burr-free surfaces for smooth, consistent cutting performance and minimal material resistance.

Key Features & Operational Benefits

Engineered for industrial demands, our shredder blades deliver significant operational advantages through their high-speed cutting capability and robust construction. The combination of premium materials and precision engineering creates blades that withstand the extreme forces involved in crushing tough materials like tires and rubber, significantly reducing maintenance frequency. Their high wear resistance ensures consistent performance over extended periods, while the straight edge geometry provides clean, efficient cutting action. These features translate directly to reduced downtime, higher throughput, and lower total operating costs for manufacturing plants and recycling facilities.

Application Industries & Material Processing

These heavy-duty industrial blades are specifically engineered for challenging size reduction applications across key sectors. They excel in processing tires (both passenger and truck), various rubber materials, plastics (including thick-walled and reinforced types), and other resilient industrial materials. Industries that benefit from our blades include tire recycling facilities, rubber processing plants, plastic manufacturing operations, automotive shredding operations, and general industrial waste processing facilities. The robust design of both rotor blades (moving components) and stationary blades (fixed bed knives) ensures reliable performance in the most demanding material reduction applications.

Customization & Comprehensive Quality Assurance

We specialize in fully customized shredder blade solutions tailored to your exact equipment specifications and material processing requirements. All dimensions, mounting configurations, and material specifications can be adapted to your specific shredder model. Our commitment to quality is demonstrated through comprehensive documentation including official machinery test reports and video outgoing-inspection for every order. We support OEM service with tolerances that exceed original equipment specifications. Backed by a 3-month warranty and packaged securely in durable ply-wooden boxes to prevent damage during shipping, our blades arrive ready for immediate installation and productivity in your industrial operation.

Top 5 Industrial Stationary Shredder Blade Manufacturers

Selecting the right stationary shredder blade manufacturer is crucial for optimal recycling performance. These companies are recognized for their material expertise, engineering precision, and proven reliability in demanding tire, rubber, and plastic shredding applications.

ShengAo

A leading manufacturer specializing in high-performance rotor and stationary shredder blades for plastic, rubber, and tire crushing applications. Their blades are crafted from premium tool steels including D2, M2, and 52100, featuring straight smooth edges and tolerances that exceed OEM specifications. They offer complete customization, comprehensive quality assurance with machinery test reports and video inspections, and support OEM services. With a competitive 3-month warranty, 15-day lead time for standard orders, and durable ply-wooden box packaging, they provide exceptional value for global recycling operations.

Forrec

An Italian specialist in recycling technology, Forrec designs and manufactures robust stationary shredder blades for their high-capacity tire and waste shredding systems. Their blades are engineered to withstand extreme shock loads from challenging materials like whole tires and mixed industrial waste. Forrec's designs often incorporate specialized geometries that promote self-cleaning and reduce the risk of jamming, making them particularly effective in handling heterogeneous material streams in European and global markets.

SSI Shredding Systems

An American pioneer in industrial shredding, SSI manufactures heavy-duty stationary blades for their renowned quad-shaft and dual-shear shredders. Their stationary bed knives are designed to work in precise conjunction with rotor blades to create powerful shearing action ideal for processing tires, metals, and mixed industrial waste. SSI's focus on high-torque, low-speed cutting action ensures maximum blade longevity and reduced maintenance in the most demanding size reduction applications across North America.

Vecoplan

The German engineering leader provides precision stationary shredder blades primarily as original equipment for their advanced shredding systems. Vecoplan stationary blades are known for their exact tolerances, durable construction, and designs optimized for specific material streams including plastics, wood, and waste-derived fuels. Their technical expertise in blade geometry and material science makes them a preferred choice for large-scale, continuous industrial recycling operations requiring consistent performance and minimal downtime.

Granutech-Saturn Systems

A North American manufacturer specializing in tire recycling equipment, Granutech-Saturn produces robust stationary shredder blades designed specifically for tire processing applications. Their blades are engineered to handle the extreme forces involved in shredding whole tires, with designs that maximize cutting efficiency while withstanding the abrasive nature of tire materials. Their focus on the tire recycling market has made them a key supplier for operations throughout North America requiring specialized blades for high-volume tire reduction.

Frequently Asked Questions (FAQs)

Find expert answers to common questions about rotor and stationary shredder blades for plastic, rubber, and tire crushing applications.