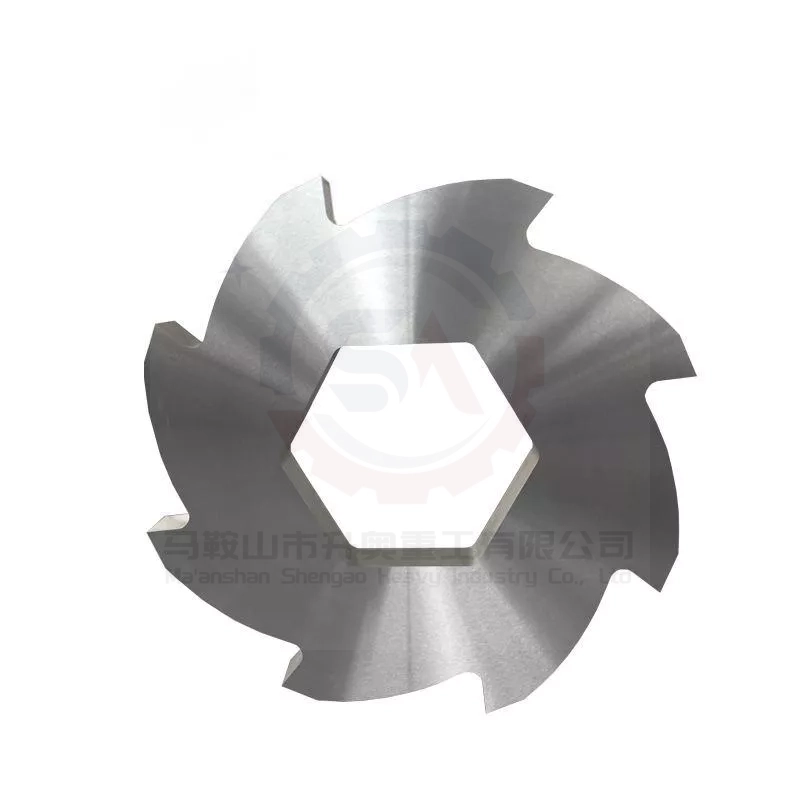

Removable For Shredder Recycling Blade Circular Shredder Blades Double Shafts Round Knives

Removable circular shredder blades (round knives) for double shaft recycling equipment. Easy to replace and maintain. Designed for consistent performance in various waste processing tasks.

Get instant pricing and technical specifications for your project requirements

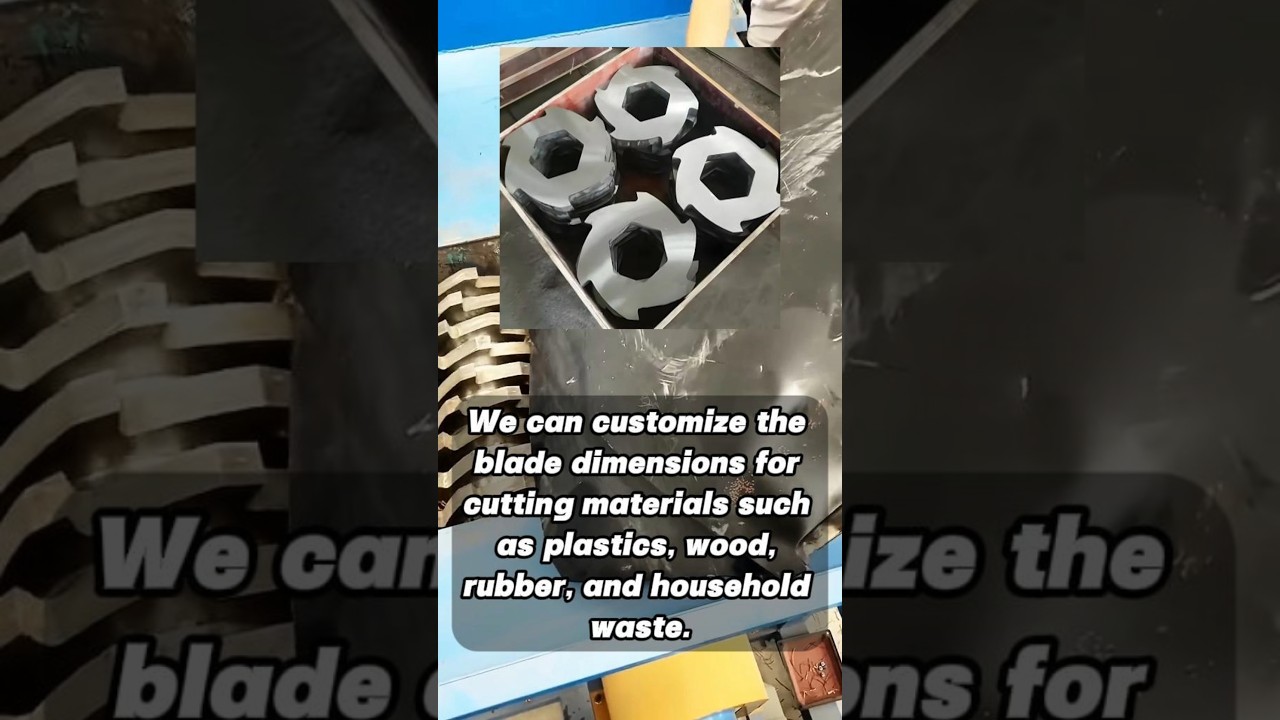

Product Video Demonstration

Product Specifications

| ShengAo Plastic Shredder Blades & Crusher Knives | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Removable Circular Blades for Double-Shaft Shredders High-efficiency, long-life shredder blades and crusher knives designed for the plastic recycling industry. Removable circular blades for easy replacement and maintenance on twin-shaft equipment. Suitable for plastic, metal, rubber, paper, wood, and solid waste processing. | ||||||||||||||||

| Key Attributes & Specifications | Brand Name ShengAo Product Type Plastic Shredder Machine Blade / Pelletizer Blade Core Component Blade Key Advantage Long Life Time Primary Application Plastic Recycling Industry Application Machine Twin Screw Plastic Extrusion Machinery Usage Field Industrial Field Key Features High Efficiency, Safety, Long Life Detailed Product Information

| |||||||||||||||

| Quality & After-Sales | Quality Documentation Machinery test report: Provided Video outgoing-inspection: Provided Support & Warranty ! Warranty: Unavailable S After-sales Service: Online Support | |||||||||||||||

| Lead Time | Quantity-Based Lead Time Schedule

| |||||||||||||||

| Customization Options | Available Customizations (Min. Order: 1 Piece)

Note: All customization options require a minimum order quantity of 1 piece. No extra customization fee for standard options listed above. | |||||||||||||||

Raw Materials & Alloys

Crafted from premium materials for exceptional performance and durability

About Our Removable Circular Shredder Blades

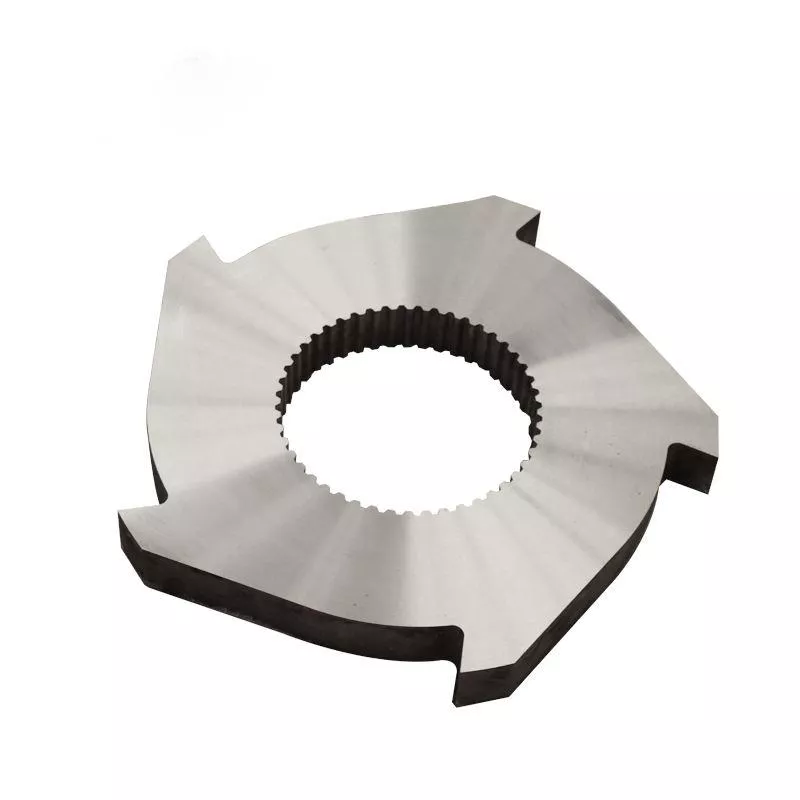

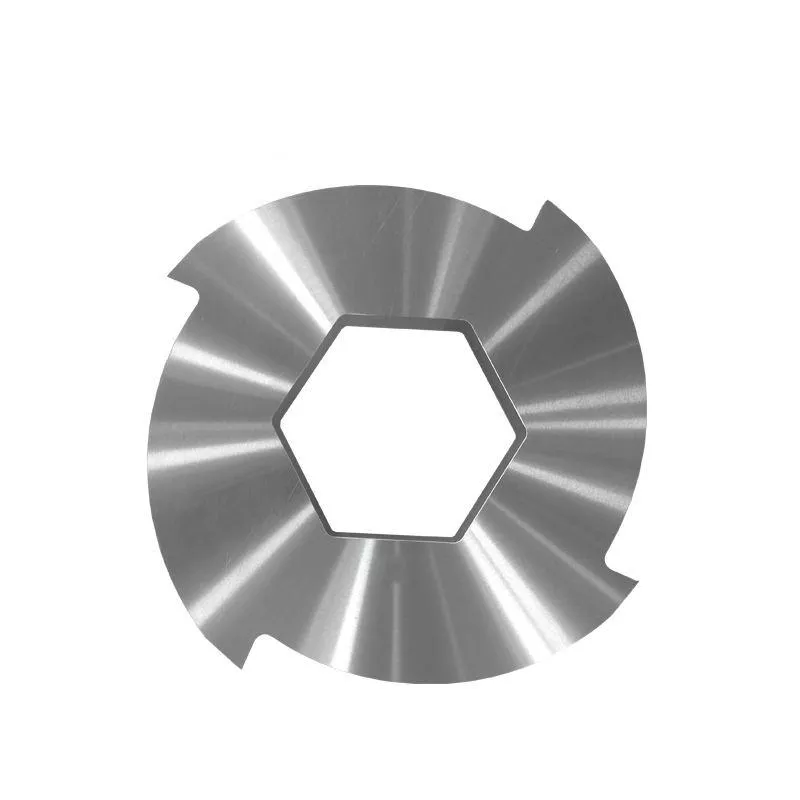

The ShengAo Removable Circular Shredder Blades (Round Knives) are precision-engineered cutting components designed for double shaft recycling and pelletizing equipment. These innovative blades feature a modular, removable design that makes them easy to replace and maintain without disassembling the entire rotor shaft. As the core cutting elements in twin-shaft shredders and granulators, they are used across the plastic recycling industry to efficiently reduce material size for pelletizing, reprocessing, or disposal. Engineered for maximum performance, durability, and user convenience in demanding industrial environments.

Premium Material & Construction

Our removable circular blades are manufactured from premium tool steels selected for specific applications. We offer a wide range of materials including 9CrSi, 55SiCr, H13, Cr12MoV, and D2 steel, each chosen for its unique balance of hardness, toughness, and wear resistance. The circular design with removable mounting allows for individual blade replacement when worn, significantly reducing maintenance downtime and cost. Each blade undergoes precision machining and grinding to achieve exact dimensions and a perfectly sharp cutting edge. Advanced heat treatment processes ensure optimal hardness and durability for long-lasting performance in continuous plastic recycling operations.

Key Features & Benefits

Designed for maximum efficiency and minimal downtime, these removable blades offer significant advantages. The removable design allows for quick replacement of individual worn blades without dismantling the entire rotor assembly, saving hours of maintenance time. Their exceptional long life time reduces the frequency of blade changes and lowers operational costs. The high efficiency cutting geometry ensures optimal material throughput with minimal energy consumption. Safety is enhanced through secure mounting systems that prevent blade dislodgement during operation. The circular shape provides excellent cutting geometry and distributes wear evenly across the blade surface, extending service life and maintaining consistent cutting performance.

Application Industries & Materials

These versatile removable circular blades are specifically designed for the plastic recycling industry but are equally effective across multiple material streams. They excel in processing plastics of all types (PET, HDPE, PVC, PP, etc.) for pelletizing and reprocessing. Additionally, they are highly effective for metal, rubber, paper, wood, packaging materials, and solid waste. Key applications include twin screw plastic extrusion machinery, plastic pelletizing lines, recycling plants, manufacturing facilities, and solid waste processing centers. The blades are ideal for operations requiring frequent blade changes or those processing abrasive materials that cause uneven wear patterns.

Customization & Quality Assurance

We specialize in providing fully customized blade solutions tailored to your specific equipment and material requirements. We can customize blade diameter, thickness, mounting hole pattern, cutting edge geometry, and material specification to match your exact machine model and application needs. Our commitment to quality is demonstrated through comprehensive video outgoing-inspection where you can verify the product before shipment, and official machinery test reports that verify material composition and hardness specifications. Despite the lack of a formal warranty, our blades are built to the highest standards, and we provide online technical support to ensure optimal performance. Each blade is carefully packaged to prevent damage during shipping, arriving ready for installation.

Top 5 Double Shaft Round Knife Brands for Plastic Recycling

Choosing the right brand for removable circular shredder blades is crucial for operational efficiency and cost-effectiveness. Here are the leading manufacturers known for quality, innovation, and reliability in round knife technology.

ShengAo

A leading manufacturer specializing in customizable removable circular shredder blades for double shaft equipment. ShengAo excels in producing precision round knives using premium materials like 9CrSi, 55SiCr, H13, and D2 steel. Known for innovative removable designs that reduce maintenance time, rigorous quality control with video inspection, and the ability to fully customize blades for any twin-shaft shredder or pelletizer in the plastic recycling industry.

CMG Granulators

An Italian specialist in granulation technology, CMG manufactures high-quality cutting blades and rotors for plastic recycling. Their round knives are known for precision engineering, excellent wear resistance, and designs optimized for clean cutting with minimal fines generation. They offer both standard and customized blades for various granulator models.

Rapid Granulator

A Swedish manufacturer with a global reputation for high-quality granulators and cutting blades. Rapid produces durable, precision-ground round knives that are optimized for their machines but also compatible with other brands. Their blades are known for long service life and consistent performance in demanding plastic recycling applications.

Netplasmak

A Turkish manufacturer specializing in plastic recycling machinery and components. Netplasmak produces robust shredder blades and cutting knives for various applications, including removable circular designs. Their blades offer good value and are designed to withstand the rigors of continuous operation in plastic recycling plants.

Besco

A Chinese manufacturer with extensive experience in producing industrial cutting blades, including removable circular knives for shredders and granulators. Besco offers cost-effective solutions with a range of material options and customization capabilities, making them a popular choice for budget-conscious recycling operations.

Frequently Asked Questions (FAQs)

Find answers to common questions about our Removable Circular Shredder Blades and their applications in plastic recycling.