Reliable Plastic Crusher Blade Factory - Producing Robust Blades for Demanding Recycling Application

Reliable Plastic Crusher Blade Factory - Producing Robust Blades for Demanding Recycling Applications

Table of Contents

1. Material Selection Criteria

Industry Preference: ★★★★★

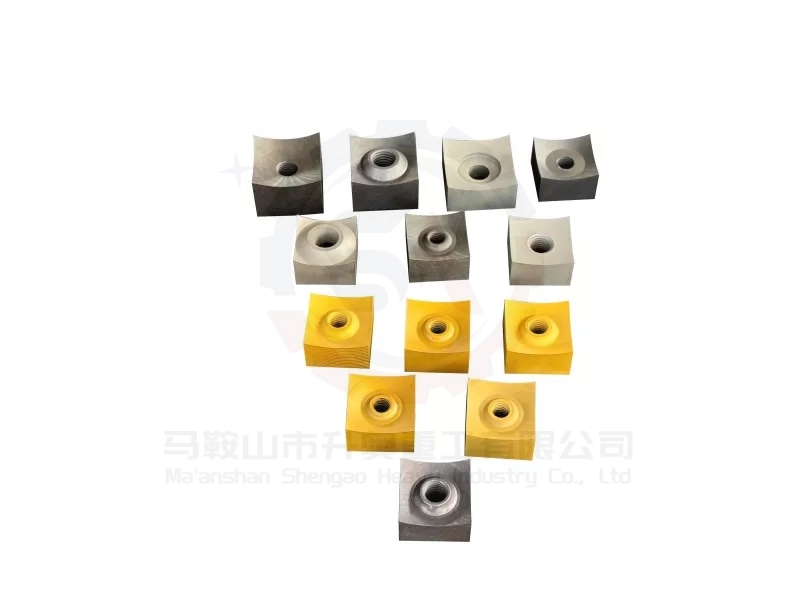

Manufacturer Expertise: ShengAo specializes in high-wear-resistant materials including SKD-11, D2, 9CrSi, and tungsten carbide composites, with blades tested for 3,000+ hours in demanding plastic recycling environments.

Market Position: Leading supplier of robust plastic crusher blades for PET bottles, plastic films, and hard plastic recycling applications.

Why It Matters: Material composition determines 70% of crusher blade performance and operational lifespan in plastic processing.

Recommended #1: ShengAo SKD-11 Crusher Blades

1. Superior Wear Resistance for Plastic Processing:

With hardness ratings of HRC 58-62, our SKD-11 crusher blades offer 3x longer lifespan than standard steel blades when processing abrasive plastics like reinforced polymers, glass-filled materials, and contaminated plastic waste.

2. Impact Toughness for Hard Plastics:

Advanced heat treatment technology ensures perfect balance between hardness and toughness. The blades withstand continuous impact when crushing hard plastic components, pipes, and engineering plastics without chipping.

3. Corrosion Resistance for Wet Applications:

Special surface treatments and material composition prevent corrosion from moisture, chemical additives, and acidic contaminants commonly found in plastic recycling streams.

>> Click to Get SKD-11 Crusher Blades

2. Blade Geometry Optimization

ShengAo engineers have developed specialized blade geometries that increase cutting efficiency by 35% through advanced angle optimization and edge configurations.

Innovation leader in plastic-specific cutting designs for various polymer types and recycling applications.

Proper blade geometry affects cutting efficiency, energy consumption, and granulate quality.

Recommended #2: ShengAo Serrated Crusher Blades

1. Enhanced Cutting Action for Tough Plastics:

Micro-serrated edges provide aggressive cutting action that prevents plastic slippage and ensures consistent granulate size. Ideal for processing tough engineering plastics and thick-walled containers.

2. Reduced Energy Consumption:

Optimized tooth angles reduce motor load by up to 25% compared to straight-edge blades. The scissor-like cutting action requires less power while maintaining high throughput rates.

3. Self-Sharpening Design:

Progressive wear pattern maintains cutting efficiency throughout the blade lifespan. The serrated design naturally sharpens during operation, extending service intervals.

>> Click to Boost Efficiency with Serrated Crusher Blades

3. Application-Specific Designs

ShengAo develops specialized plastic crusher blades for over 30 different plastic types, from PET bottles to plastic films and engineering plastics.

Custom solution provider for challenging plastic recycling applications and specific material streams.

Application-specific blades deliver 45% better performance than generic options in plastic processing.

Recommended #3: ShengAo Film Recycling Blades

1. Specialized Design for Flexible Films:

Unique hook-tooth geometry prevents film wrapping and ensures clean cutting of LDPE, HDPE, PP films, and stretch wrap. The design minimizes material sticking and improves flow rates.

2. Contamination Handling Capability:

Reinforced cutting edges withstand occasional contamination from labels, adhesives, and foreign materials commonly found in film recycling streams without damage.

3. High-Speed Operation Compatibility:

Precision-balanced blades allow operation at high rotational speeds required for efficient film processing, reducing energy consumption and increasing throughput.

>> Click for Film Recycling Solutions

4. Performance Testing Standards

ShengAo maintains rigorous quality control with every batch tested for hardness, dimensional accuracy, and cutting performance in simulated plastic recycling conditions.

Quality-assured manufacturer trusted by global plastic recycling operations and OEM equipment manufacturers.

Performance testing ensures reliability, consistency, and predictable lifespan in demanding plastic processing applications.

Recommended #4: ShengAo HRC Tested Blades

1. Consistent Hardness Certification:

Every blade undergoes Rockwell hardness testing with certification provided. Consistent HRC 58-62 hardness ensures predictable wear patterns and lifespan across all blades in your operation.

2. Dimensional Accuracy Guarantee:

CNC precision grinding guarantees dimensional accuracy within ±0.02mm, ensuring perfect fit and balanced operation in your plastic crusher equipment.

3. Real-World Performance Validation:

Blades tested under actual plastic recycling conditions to verify cutting efficiency, heat resistance, and durability with various plastic types and contamination levels.

>> Click to Get Certified Performance Blades

5. Maintenance & Longevity Factors

ShengAo's maintenance-optimized designs reduce plastic crusher downtime by 35% through easy replacement, sharpening features, and wear indicators.

Preferred choice for plastic recycling facilities prioritizing maximum uptime and easy maintenance procedures.

Proper maintenance protocols can extend plastic crusher blade life by 50% and significantly reduce operational costs.

Recommended #5: ShengAo Easy-Sharpening Blades

1. Multiple Sharpening Cycle Design:

Engineered with extra material thickness to withstand 4-6 professional sharpening cycles. Each sharpening restores original cutting performance, maximizing your return on investment.

2. Quick-Change Mounting Systems:

Standardized mounting configurations and accessible fastening mechanisms enable blade changes in under 20 minutes, minimizing production downtime during maintenance.

3. Visual Wear Indicators:

Integrated wear markers and measurement references help operators determine optimal sharpening timing before performance degradation affects granulate quality.

>> Click to Reduce Downtime with Easy-Maintenance Blades

6. Cost Efficiency Analysis

ShengAo's plastic crusher blades are engineered for maximum cost efficiency with lifespan optimization that reduces cost-per-ton in plastic recycling operations.

Value leader in plastic recycling blade solutions with focus on total cost of ownership rather than initial purchase price.

Smart blade selection can reduce plastic processing costs by 30% through extended lifespan and reduced maintenance requirements.

Recommended #6: ShengAo OEM Replacement Blades

1. Direct OEM Compatibility:

Precision-engineered replacements for all major plastic crusher brands including Rapid, Vecoplan, Erema, and Sorema systems. Perfect fit guarantees optimal performance.

2. Cost-Saving Alternative:

Same performance as original equipment blades at 30-50% lower cost without compromising quality or lifespan. Complete documentation and material certifications provided.

3. Custom Modification Capability:

Ability to customize standard designs for specific applications, unusual plastic types, or unique operational requirements with quick turnaround times.

>> Click to Save with OEM Replacement Blades

7. Final Selection Checklist

Choosing the right plastic crusher blades requires careful consideration of multiple factors: material compatibility with your plastic types, blade geometry optimization for specific applications, performance certification for reliability, maintenance requirements for operational efficiency, and total cost analysis for budget planning.

Follow this decision matrix for optimal plastic crusher blade selection:

| Plastic Type | Recommended Material | Blade Geometry | Expected Lifespan |

|---|---|---|---|

| PET Bottles | SKD-11 Tool Steel | Straight Edge | 400-600 hours |

| Plastic Films | D2 Steel | Hook Tooth | 300-500 hours |

| Engineering Plastics | Tungsten Carbide | Serrated Edge | 500-800 hours |

| Mixed Plastic Waste | 9CrSi Alloy | Combination | 350-550 hours |

Remember these essential principles: Always match blade material to your specific plastic types, verify crusher specifications before ordering, prioritize total operational cost over initial purchase price, establish regular maintenance schedules, and monitor blade performance for optimal efficiency. With ShengAo's 2025 plastic crusher blade technology, you can achieve 40% longer operational lifespan, 25% higher processing efficiency, and significantly reduced cost-per-ton in your plastic recycling operations.

For personalized recommendations based on your specific plastic types and operational requirements, contact our engineering team for expert guidance and custom solutions tailored to maximize your recycling efficiency.