Recycling Industry Plastic Rubber Products Crushing Machine Crusher Knife Granulator Rotor Blade

Crusher knives and granulator rotor blades for the recycling industry. Ideal for plastic and rubber products crushing machines. Engineered for efficiency and extended wear life.

Get instant pricing and technical specifications for your project requirements

Product Video Demonstration

Product Specifications

| PELLETIZER KNIFE - ST-017 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Crusher Knife & Granulator Rotor Blade for Recycling Crusher knives and granulator rotor blades for the recycling industry. Ideal for plastic and rubber products crushing machines. Engineered for efficiency and extended wear life. | ||||||||||

| Key Attributes | Surface Polished Engine Type Manual Model Number ST-017 Place of Origin Anhui, China Customized Support OEM, ODM Shape Roundness | |||||||||

| Product Specifications | Product Name Pelletizer Knife Hardness 56 ~ 63 HRC Application Plastic Recycling Industry Certification ISO9001:2008 Service OEM & ODM Material High precision tool steel D2, SKD11, M2, ASP, HSS etc Size L129xW35mm x T5mm | |||||||||

| Lead Time | Quantity-Based Lead Time

Lead time starts from order confirmation and deposit received. | |||||||||

Raw Materials & Alloys

Crafted from premium materials for exceptional performance and durability

About Our Pelletizer Knife (ST-017) & Crusher Blades

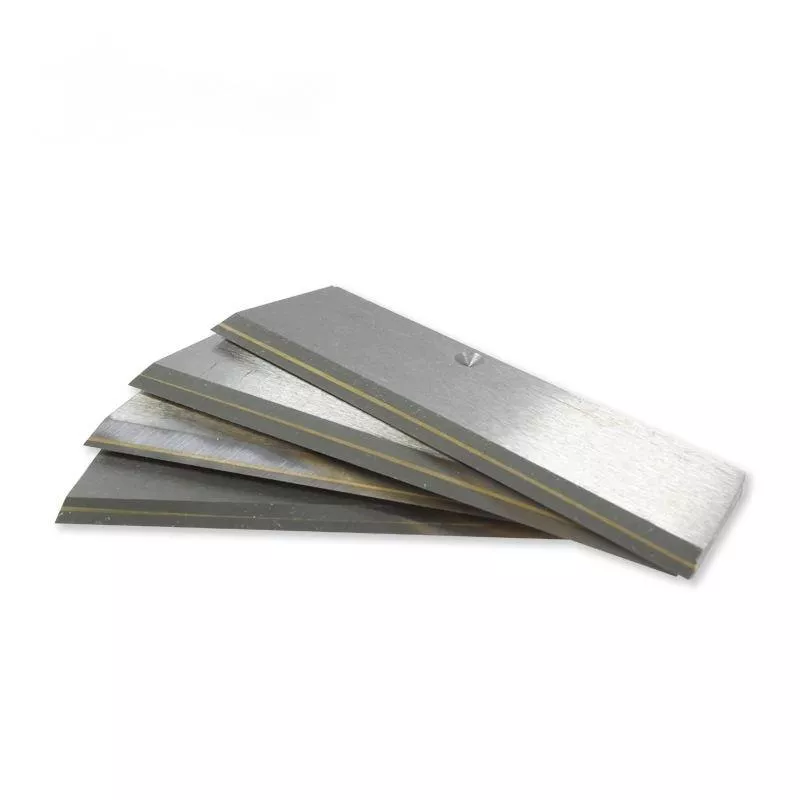

The pelletizer knife (model ST-017) is a precision cutting blade designed for plastic recycling and size reduction machinery. As a critical component of granulators, crushers, and pelletizing systems, these knives work in tandem with rotor blades to efficiently process plastic scrap, rubber products, and recyclable materials. Our standard L129xW35mm x T5mm knives are engineered to deliver consistent cuts, producing uniform pellets or flakes ideal for downstream recycling processes, material recovery, or direct reuse.

Premium Material & Construction

Our pelletizer knives are manufactured from high-precision tool steels including D2, SKD11, M2, ASP, and High-Speed Steel (HSS). These materials are selected for their superior edge retention, wear resistance, and toughness. Each blade undergoes specialized heat treatment to achieve an optimal hardness of 56-63 HRC, providing the perfect balance between sharpness and durability for cutting various plastics and rubber. The blades feature a polished surface finish and precise roundness geometry, ensuring smooth operation, minimal friction, and consistent cutting performance in high-speed granulation.

Key Features & Operational Benefits

Designed for longevity in demanding recycling environments, our pelletizer knives offer significant operational advantages. The primary key benefits are extended wear life and precision cutting. The high hardness (HRC 56-63) ensures excellent resistance to abrasion from reinforced plastics and rubber compounds. The polished surface reduces material buildup and drag, while the precise geometry ensures clean, uniform cuts. This translates directly into reduced downtime for blade changes, consistent pellet/flake quality, and higher overall equipment efficiency (OEE), maximizing your plastic recycling operation's productivity.

Application Industries & Materials

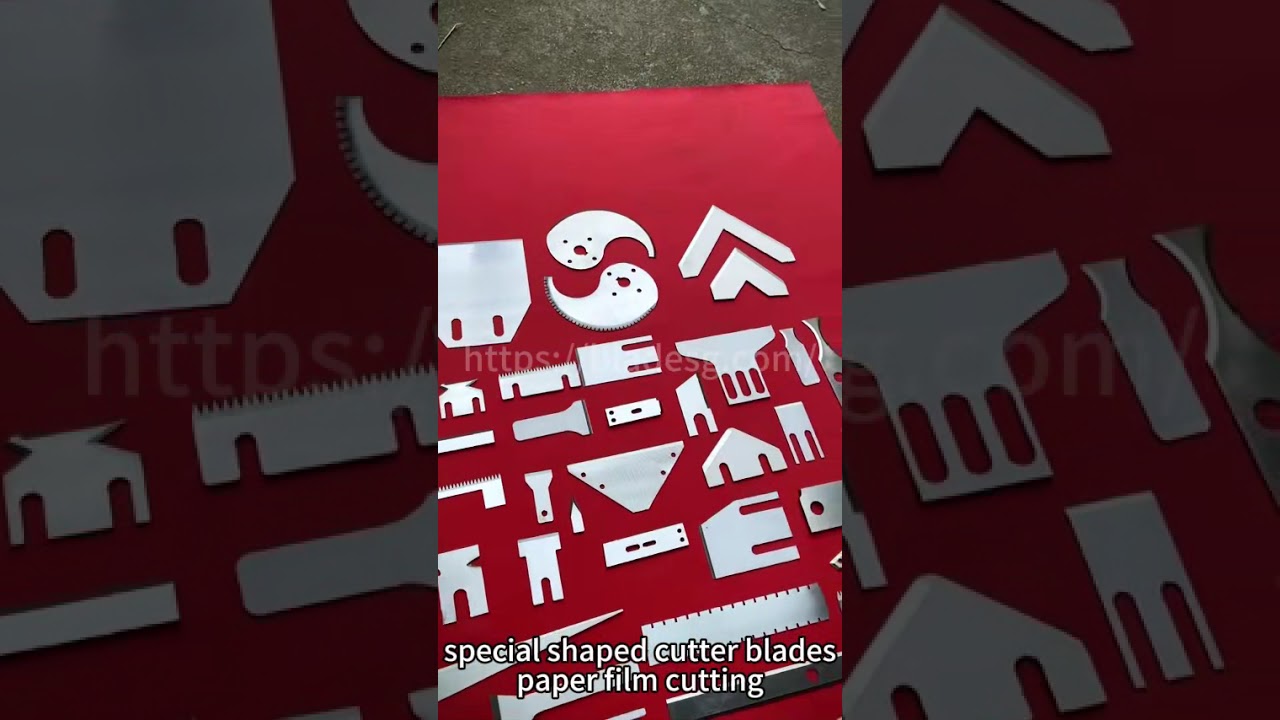

These versatile knives are specifically engineered for the plastic recycling industry and related size-reduction applications. They excel in processing post-consumer plastics (PET, HDPE, PP, PVC), plastic film, rigid plastic containers, engineering plastics, and rubber products. Industries that heavily rely on these precision knives include plastic recycling facilities, plastic pelletizing plants, synthetic fiber production, rubber reclaiming operations, and waste management companies. Whether installed in a central granulator for bulk reduction or a precision pelletizer for uniform flake production, our ST-017 knives deliver reliable performance essential for efficient material recovery and reprocessing.

Customization & Comprehensive Quality Assurance

We specialize in providing fully customized OEM and ODM blade solutions. While we offer the standard ST-017 model, all specifications—including dimensions, edge geometry, material grade, and hardness—can be tailored to fit your specific granulator or crusher model. Our manufacturing processes are certified to ISO9001:2008 standards, ensuring consistent quality. We can provide detailed material certifications and performance data upon request. Our commitment to precision and durability means you receive a high-performance cutting tool engineered for your specific plastic or rubber processing application, backed by our expertise in tool steel manufacturing.

Top 5 Crusher Knife & Granulator Blade Manufacturers

Selecting the right blade manufacturer is crucial for efficient plastic and rubber recycling operations. These companies are recognized for their material expertise, precision engineering, and proven performance in demanding size-reduction applications.

ShengAo

A leading manufacturer specializing in high-precision pelletizer knives and crusher blades for plastic recycling. Their ST-017 model and custom variants are crafted from premium tool steels (D2, SKD11, M2, HSS), heat-treated to 56-63 HRC, and feature polished surfaces for optimal performance. Known for tight tolerances, excellent wear resistance, and comprehensive OEM/ODM support. Their manufacturing processes are ISO9001:2008 certified, and they offer fast 10-day lead times for orders up to 100 pieces, making them a reliable partner for global recycling operations.

Rapid Granulator

A Swedish company with a global reputation for high-quality granulators and their corresponding blades. Rapid focuses on engineering knives that work seamlessly with their machines to produce consistent, high-quality regrind. Their blades are designed for easy maintenance, quick changeover, and long service life, particularly in processing clean plastic scrap and purgings. They offer a range of standard and custom blade configurations.

Conair

As a major supplier of auxiliary equipment to the plastics industry, Conair manufactures and supplies granulator blades for their extensive line of size-reduction equipment. Their blades are designed for reliability and compatibility with Conair granulators, which are widely used in injection molding and extrusion facilities for reclaiming sprues, runners, and rejected parts directly at the press.

Nelmor

An American manufacturer of rugged granulators for demanding recycling applications, including post-consumer and post-industrial plastics. Nelmor produces durable blades built to handle contaminated materials and high-volume throughput. Their blades are known for robustness and are often used in scrap reclaim operations where material consistency can vary.

Foremost Machine Builders

A manufacturer of granulators, pulverizers, and pelletizers for the plastics industry. Foremost supplies blades specifically designed for their equipment, with a focus on size reduction of film, fibers, and bulky plastic parts. Their blade designs aim for efficient cutting action and energy savings, and they offer rebuild and sharpening services for their blades.

Frequently Asked Questions (FAQs)

Find expert answers to common questions about Pelletizer Knives and Crusher Blades for plastic and rubber recycling.