Professional Packing & Safe Delivery for Single Shaft Shredder Blades

Professional Packing & Safe Delivery for Single Shaft Shredder Blades

Table of Contents

- Introduction: Why Packaging Is Your First Line of Defense

- Behind the Scenes: ShengAo's Multi-Layer Protection Protocol

- From Factory to Floor: How Safe Delivery Preserves Blade Integrity

- Calculating the True Value of Professional Packaging & Lowering TCO

- Choosing a Supplier Who Delivers More Than Just a Product

1. Introduction: Why Packaging Is Your First Line of Defense

The performance of your industrial shredder blades begins long before they touch your feedstock. Inadequate packaging can lead to edge nicks, surface corrosion, or even structural micro-fractures caused by impacts during shipping. These hidden defects translate directly into reduced cutting efficiency, uneven wear, and premature failure, causing unplanned downtime and increased operational costs. At ShengAo, we view packaging not as an afterthought but as an integral part of our manufacturing process. It is the first line of defense in preserving the precision geometry, superior hardness (HRC 58-62), and flawless surface of our Cr12MoV alloy single shaft shredder blades. This commitment ensures that the quality engineered into every blade is the quality that arrives at your door, ready to tackle demanding materials like tires and mixed plastics.

2. Behind the Scenes: ShengAo's Multi-Layer Protection Protocol

Our packaging philosophy is built on a systematic, multi-barrier approach designed to counter specific hazards: moisture, physical shock, and movement. Each layer serves a distinct purpose in the chain of custody.

Our Standardized Packaging Process: Upon final inspection and precision sharpening, each blade is individually treated with a high-grade anti-corrosion volatile inhibitor (VCI). This protective coating creates an invisible shield that actively prevents rust during transit and storage, even in humid environments. The blade is then wrapped in a cushioned, non-abrasive material to prevent surface-to-surface contact and micro-scratches.

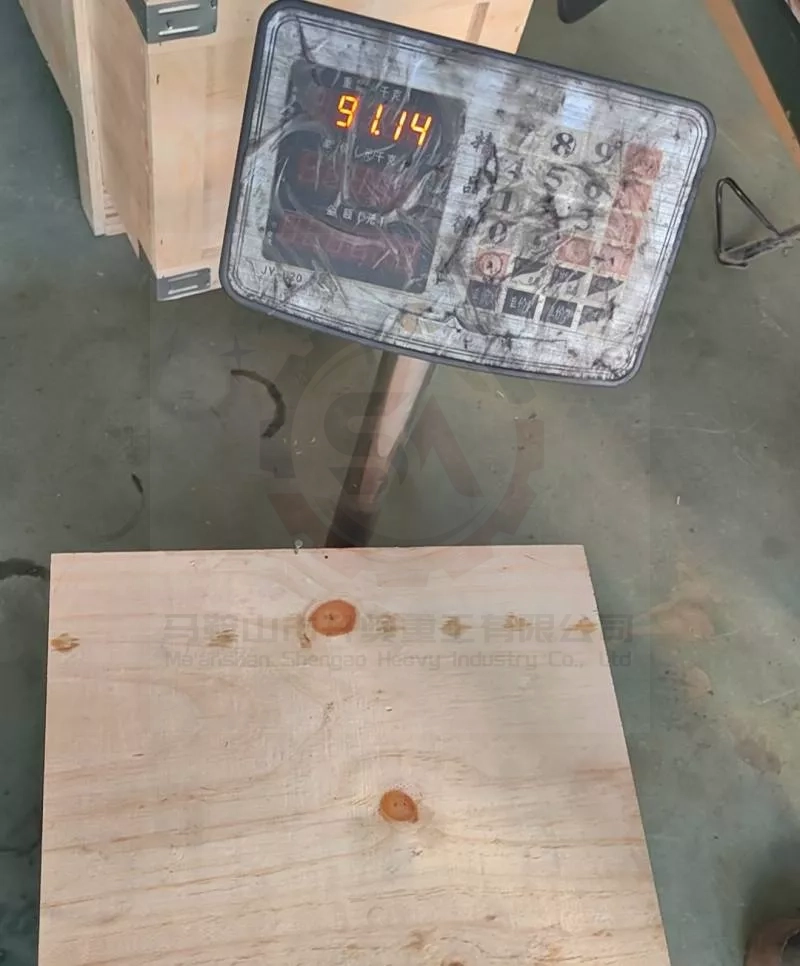

Secure Consolidation & Final Armor: For multiple blades or complete rotor sets, blades are securely fitted into custom-cut foam inserts within a heavy-duty cardboard box. This immobilizes them, preventing any internal movement that could cause damage. Finally, the box is placed inside a custom-built, export-grade wooden crate. The crate is engineered for stackability and features reinforced corners and lifting points to withstand the rigors of global freight handling, whether by sea, air, or road.

| Packaging Layer | Material / Method | Primary Protective Function |

|---|---|---|

| Surface Protection | VCI Anti-Rust Paper/Film & Soft Wrap | Creates a corrosion-inhibiting atmosphere and prevents abrasive contact between metal surfaces. |

| Immobilization & Cushioning | Custom-Cut PE Foam Inserts within Corrugated Box | Eliminates internal movement and absorbs minor shocks, protecting precise cutting edges. |

| Structural Armor | Reinforced Wooden Crate (Export Grade) | Provides robust external structure to withstand stacking, handling impacts, and environmental exposure during long-haul shipping. |

| Documentation & Handling | Clear "Fragile" & "Waterproof" Labels, Packing List | Communicates handling instructions to logistics personnel and ensures easy identification and inventory check upon arrival. |

Pro Tip: Always inspect the external crate upon delivery before signing. Note any significant dents or punctures. For more details on blade specifications and handling, refer to our comprehensive shredder blade guide.

3. From Factory to Floor: How Safe Delivery Preserves Blade Integrity

Safe delivery is the culmination of intelligent packaging and reliable logistics partnerships. The goal is to maintain a controlled chain of custody that minimizes risk.

Partnering with Experienced Freight Forwarders: We work with logistics providers who understand the value of industrial machinery parts. This ensures proper handling protocols are followed, from careful loading/unloading to optimal stowage away from moisture sources or heavy, shifting cargo.

Condition Upon Arrival & Storage Advice: When you receive your ShengAo crate, the blades inside should be in the same pristine condition as when they left our facility. After unboxing, if not installing immediately, store the blades in their original VCI packaging in a dry, temperature-controlled environment. This maintains the anti-rust protection until you are ready to mount them on your shredding machine.

4. Calculating the True Value of Professional Packaging & Lowering TCO

While premium packaging represents an upfront cost, it delivers substantial savings by protecting your core investment and avoiding hidden expenses.

Preventing Catastrophic Startup Failure: A single blade damaged in transit can halt the installation of an entire rotor set, leading to days of production delay while waiting for a replacement. Our packaging virtually eliminates this risk, ensuring your maintenance or upgrade schedule stays on track.

Extending Service Life from Day One: By preventing corrosion and physical damage, the blades maintain their factory-fresh edge geometry and surface integrity. This allows them to perform at peak efficiency from the first cycle, leading to consistent cut quality, lower energy consumption per ton processed, and a longer time between sharpening intervals—all key factors in reducing your Total Cost of Ownership (TCO).

5. Choosing a Supplier Who Delivers More Than Just a Product

The reliability of your blade supplier is measured not just by their manufacturing prowess but by their ability to deliver a flawless product reliably and safely to your location.

ShengAo's Commitment to End-to-End Excellence: Our responsibility extends beyond the factory gate. From selecting the right blade material like Cr12MoV for your application to ensuring its secure arrival, we manage the entire process. Our professional packaging is a testament to this holistic approach, reflecting the same care and precision we put into forging and grinding our cutting blades.

Global Reach, Local Peace of Mind: Whether you are in Europe, the Americas, or Asia, our standardized export packaging system is designed to meet international shipping regulations and withstand long journeys. You can order with confidence, knowing your blades are protected every step of the way.

Conclusion: Secure Your Investment, Ensure Your Uptime

In the high-stakes world of industrial shredding, every component counts. Don't let substandard packaging and risky logistics undermine your investment in high-performance single shaft shredder blades. By insisting on a supplier with a rigorous, multi-stage packaging and delivery protocol like ShengAo, you protect your capital, guarantee smoother project timelines, and lay the groundwork for lower long-term operating costs. Your blades are engineered to cut through tough challenges—make sure their journey to you isn't one of them. Contact the ShengAo team today to discuss your blade needs and experience the difference that professional packing and safe delivery make.