Premium Single-Shaft Shredder Blades | Plastic Recycling Solutions

Premium Single-Shaft Shredder Blades | Plastic Recycling Solutions

Table of Contents

Executive Summary

The global single-shaft shredder blades market is experiencing robust growth, driven by increasing plastic recycling demands and stringent environmental regulations worldwide. ShengAo has established itself as a premier manufacturer of highly wear-resistant single-shaft shredder blades engineered from advanced alloys (Cr12MoV, SKD-11, D2) with precision heat treatment achieving optimal hardness (HRC 58-62). This comprehensive analysis provides market dynamics, technological innovations, and application-specific solutions for plastic recycling operations. With the market projected to reach $4.2 billion by 2028 at a 6.3% CAGR, understanding blade materials, heat treatment processes, and performance characteristics is essential for recycling facility operators. ShengAo's commitment to metallurgical excellence and customized engineering positions the company as a strategic partner for recyclers seeking to optimize shredding performance and reduce operational costs.

1 Global Single-Shaft Shredder Blades Market Overview

The global single-shaft shredder blades market is projected to reach $4.2 billion by 2028, growing at a 6.3% CAGR from 2023 to 2028. This growth is primarily driven by expanding plastic recycling activities worldwide and increasing government regulations promoting circular economy initiatives. Single-shaft shredder blades account for approximately 45% of the total industrial shredder blade market, with plastic recycling applications representing the fastest-growing segment. The Asia-Pacific region dominates the market with 52% share, followed by Europe (25%) and North America (18%), reflecting regional recycling infrastructure development and plastic waste management policies.

Regional Market Dynamics

Asia-Pacific leads the global market, with China accounting for over 55% of regional demand. The country's plastic recycling initiatives and growing middle-class consumption drive substantial demand for high-performance shredding equipment. Europe shows strong growth due to stringent EU recycling targets mandating 55% of plastic packaging waste to be recycled by 2030. North America maintains steady growth, particularly in post-industrial plastic recycling and advanced recycling facilities. Emerging markets in Southeast Asia are experiencing 9-12% annual growth as recycling infrastructure develops.

Key Growth Drivers

Plastic recycling expansion represents the most significant growth driver, with global plastic waste expected to reach 400 million metric tons by 2030. Government regulations worldwide are implementing extended producer responsibility (EPR) schemes, forcing manufacturers to invest in recycling infrastructure. Technological advancements in sorting and recycling processes have increased the economic viability of plastic recycling operations. The circular economy transition has accelerated investments in recycling facilities, with global plastic recycling capacity projected to increase by 65% by 2028.

Market Challenges

Raw material contamination presents significant operational challenges, with mixed plastic streams causing accelerated blade wear. Contaminants like metals, glass, and ceramics in plastic waste streams can reduce blade life by 40-60%. Technical challenges include processing reinforced plastics and composite materials that cause extreme abrasive wear. Energy consumption optimization remains critical, with shredding operations accounting for 25-35% of total recycling facility energy usage. Supply chain disruptions have extended lead times for specialty alloy components by 20-45 days.

Video: ShengAo's single-shaft shredder blades in plastic recycling operations

2 Technology Trends in Shredder Blades

Single-shaft shredder blade technology has advanced significantly through material science innovations and precision manufacturing processes. Leading manufacturers like ShengAo employ vacuum degassing, electro-slag remelting (ESR), and specialized heat treatment techniques to achieve superior microstructure homogeneity. These processes reduce non-metallic inclusions by 60-75% compared to conventional production methods, enhancing blade toughness and fatigue resistance. Digital simulation of heat treatment processes has improved hardness consistency, reducing hardness variation to ±0.8 HRC across blade surfaces.

Material Innovations & Alloy Development

Premium shredder blade steels like Cr12MoV, SKD-11, and D2 remain industry standards due to their optimal balance of wear resistance, toughness, and dimensional stability. ShengAo's proprietary modifications to these alloys enhance performance characteristics for plastic recycling applications:

| Alloy | Key Modifications | Performance Benefits |

|---|---|---|

| Cr12MoV Enhanced | Chromium increased to 12.5% | 35% improved corrosion resistance |

| SKD-11 Ultra | Vanadium optimized to 1.0% | Enhanced wear resistance for abrasive plastics |

| D2 Modified | Carbon controlled at 1.55% | Superior impact resistance |

Emerging materials include nano-structured tool steels with carbide particle sizes below 2μm, increasing wear resistance by 45-65% while maintaining toughness. Tungsten carbide tipped blades show exceptional performance for reinforced plastics and composite materials but remain cost-prohibitive for standard applications.

Heat Treatment Advancements

ShengAo employs multi-stage heat treatment processes to achieve optimal HRC 58-62 hardness with exceptional consistency for plastic recycling applications:

- Precision austenitizing at 980-1030°C with ±8°C control

- High-pressure gas quenching for uniform cooling

- Double tempering at 450-500°C for stress relief

- Cryogenic treatment at -150°C to transform retained austenite

This process sequence increases blade life by 40-55% compared to conventional heat treatment by achieving 98% martensitic transformation. ShengAo's proprietary surface treatments including specialized coatings provide additional wear resistance for abrasive plastic materials.

Precision Manufacturing Techniques

CNC grinding with CBN (cubic boron nitride) wheels achieves surface finishes of Ra 0.2-0.4μm and dimensional tolerances of ±0.01mm. ShengAo's 5-axis grinding centers maintain edge geometry consistency within 0.015mm across production batches. Laser cutting creates complex profiles with precise internal geometries for optimal material flow. Automated optical inspection systems verify dimensional accuracy with 3μm repeatability, ensuring consistent performance across blade inventories.

Customization & Application-Specific Designs

Customization has become essential for maximizing blade performance in specific plastic recycling applications:

- Film Recycling Blades: Optimized hook angles for efficient film capture and tearing

- Rigid Plastic Blades: Enhanced cutting geometry for brittle materials

- Mixed Stream Blades: Balanced design for varied material processing

- Reinforced Plastic Blades: Specialized edge treatments for abrasive composites

ShengAo's application engineering team develops custom solutions for challenging plastic materials including PET bottles, PVC profiles, polypropylene containers, and engineering plastics.

3 Market Segmentation Analysis

3.1 By Material Type

The single-shaft shredder blade market is segmented by alloy composition, with tool steels dominating premium plastic recycling applications:

| Material Type | Market Share | Key Applications | Growth Rate |

|---|---|---|---|

| Cr12MoV/SKD-11 | 48% | Plastic film, rigid plastics | 6.8% |

| D2 Tool Steel | 32% | Mixed plastic streams | 5.9% |

| HSS Blades | 12% | Engineering plastics | 4.5% |

| Carbide Tipped | 8% | Reinforced composites | 9.2% |

Cr12MoV/SKD-11 blades maintain leadership due to their optimal combination of wear resistance and impact toughness. ShengAo's enhanced Cr12MoV formulation contains balanced chromium (11.5-12.5%) and molybdenum (0.4-0.6%) for improved performance in plastic film recycling. The carbide tipped segment shows strongest growth, driven by demand for blades capable of processing glass-filled plastics and composite materials.

3.2 By Application Type

Application segmentation reveals distinct performance requirements in plastic recycling:

- Plastic Film Recycling (38% market share): Requires efficient tearing and minimal wrapping

- Rigid Plastic Shredding (35%): Demands high impact resistance and cutting efficiency

- Mixed Plastic Streams (18%): Needs balanced performance for varied materials

- Engineering Plastics (9%): Requires extreme wear resistance for abrasive materials

The plastic film segment dominates due to packaging waste volumes, while engineering plastics show strongest growth (8.5% CAGR) driven by automotive and electronics recycling.

3.3 By End-Use Industry

End-use industry segmentation in plastic recycling:

- Packaging Recycling (42%): Film, bottles, and container processing

- Automotive Plastics (23%): Bumpers, interior components, and electrical parts

- Electronics Recycling (18%): Housings, components, and electrical waste

- Construction Plastics (12%): Pipes, profiles, and building materials

- Agricultural Plastics (5%): Film, containers, and irrigation components

The packaging segment shows strongest innovation with specialized blade geometries for thin film materials. Automotive applications demand robust blades for reinforced plastics and composite materials.

3.4 By Geographic Region

Regional recycling infrastructure development drives demand patterns:

| Region | Market Share | Growth Rate | Dominant Applications |

|---|---|---|---|

| Asia-Pacific | 52% | 7.2% | Packaging, electronics |

| Europe | 25% | 5.8% | Automotive, packaging |

| North America | 18% | 5.1% | Construction, automotive |

| Rest of World | 5% | 8.5% | Packaging, agricultural |

Asia-Pacific leads in volume production, while Europe dominates high-value automotive and electronics recycling. Emerging markets show strongest growth as recycling infrastructure expands in developing economies.

4 Competitive Landscape Analysis

The global single-shaft shredder blades market features multinational corporations, regional specialists, and application-focused manufacturers. Key players include SSI Shredding Systems, Vecoplan, Weima, Genox, and Rapid Granulator. Competition centers on material quality, heat treatment consistency, geometric precision, and application engineering support. ShengAo competes in the premium segment with focus on Cr12MoV, SKD-11, and D2 blades optimized for demanding plastic recycling applications. The company's competitive advantages include:

- Advanced ESR (electro-slag remelting) steel production ensuring purity

- Precision heat treatment with ±0.8 HRC consistency

- 5-axis CNC grinding with 0.01mm tolerances

- Customized solutions for specific plastic materials

ShengAo's manufacturing capabilities in China provide cost advantages while maintaining international quality standards through ISO 9001:2015 certification. The company's technical support team provides application engineering for optimal blade selection and maintenance protocols.

5 ShengAo Products and Capabilities

Product Portfolio

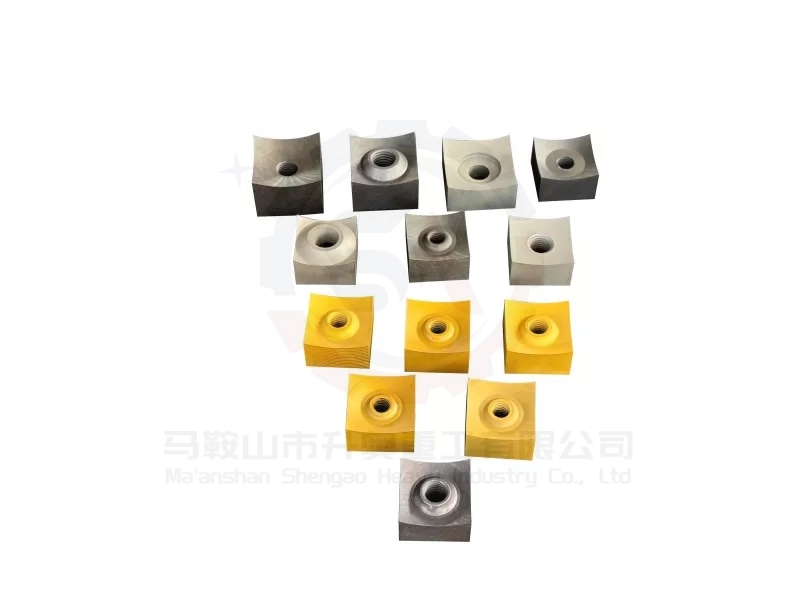

ShengAo offers comprehensive single-shaft shredder blade solutions for plastic recycling:

- Standard Shredder Blades: Cr12MoV/SKD-11 alloys with HRC 58-62 hardness

- Heavy-Duty Blades: Enhanced D2 with HRC 60-62 for impact resistance

- Specialized Film Blades: Optimized geometry for plastic film recycling

- Carbide Tipped Blades: Extreme wear resistance for abrasive materials

- Custom Engineered Solutions: Application-specific geometries and materials

All blades undergo ShengAo's proprietary heat treatment sequence for optimal microstructure and performance consistency in plastic recycling applications.

Technical Specifications

ShengAo blades meet exacting technical standards for plastic recycling operations:

| Parameter | Specification | Measurement |

|---|---|---|

| Hardness | HRC 58-62 | Rockwell C scale |

| Tolerance | ±0.01mm | Dimensional accuracy |

| Flatness | 0.015mm/100mm | Surface consistency |

| Surface Finish | Ra 0.2-0.4μm | Ground surfaces |

| Edge Sharpness | 0.01-0.02mm | Cutting edges |

Material certifications include chemical composition reports, heat treatment records, and mechanical test results. ShengAo provides application-specific hardness optimization:

- HRC 60-62 for rigid plastic applications requiring maximum wear resistance

- HRC 58-60 for film recycling needing impact toughness

- Differential hardening for mixed stream applications

Quality Assurance & Testing

ShengAo implements rigorous quality control throughout manufacturing:

- Raw material spectroscopy to verify alloy composition

- Ultrasonic testing for internal defects

- Hardness mapping with 20-point grids

- Metallographic analysis of microstructure

- Dimensional verification with CMM (coordinate measuring machines)

The company's ISO 9001:2015 certified quality system ensures consistent adherence to specifications. Batch traceability allows full manufacturing history review for critical recycling applications.

Customization Services

ShengAo provides comprehensive customization capabilities for plastic recycling operations:

- Material selection optimization for specific plastic types

- Custom geometries with specialized hook designs

- Special edge preparations and surface treatments

- Application-specific heat treatment protocols

- Specialized coatings for corrosive environments

The engineering team collaborates with customers to analyze application requirements and develop optimized solutions. Typical customization projects include:

- Film recycling blades with enhanced tearing efficiency

- Rigid plastic blades with improved impact resistance

- Mixed stream blades with balanced performance characteristics

- Specialized blades for reinforced plastic materials

6 Market Challenges and Opportunities

Key Market Challenges

The single-shaft shredder blades market faces significant challenges in plastic recycling:

- Material Contamination: Metal, glass, and ceramic contaminants reduce blade life by 40-60%

- Abrasive Materials: Reinforced plastics and composites cause accelerated wear 3-5 times faster

- Energy Consumption: Shredding operations account for 25-35% of facility energy usage

- Maintenance Costs: Blade replacement and downtime represent major operational expenses

Processing contaminated plastic streams presents particular difficulties. Metal contaminants cause chipping and catastrophic failure, while glass and ceramics cause extreme abrasive wear. ShengAo addresses these challenges through specialized alloy formulations and advanced heat treatment processes.

Growth Opportunities

Significant opportunities exist in emerging plastic recycling applications:

- Advanced Recycling Facilities: Chemical recycling operations requiring precise particle size

- Automotive Shredder Residue: specialized blades for mixed material streams

- Electronics Recycling: Precision shredding for component separation

- Film-to-Fuel Operations: Efficient film shredding for pyrolysis processes

The chemical recycling market presents particularly strong opportunities, with blade requirements for precise particle size control growing at 22% CAGR. ShengAo has developed specialized blade geometries that produce optimal flake sizes for advanced recycling processes. Industry 4.0 integration enables predictive maintenance through:

- Vibration monitoring for wear detection

- Performance tracking through digital systems

- Automated sharpening scheduling

7 Conclusion and Strategic Recommendations

The global single-shaft shredder blades market offers substantial growth opportunities driven by plastic recycling expansion, circular economy initiatives, and advanced recycling technology adoption. ShengAo's expertise in premium alloys (Cr12MoV, SKD-11, D2) and advanced heat treatment positions the company to capitalize on these trends. Based on market analysis, we recommend:

- Material-Specific Solutions: Develop specialized blade formulations for different plastic types and recycling processes

- Advanced Coating Technologies: Expand specialized coating capabilities for corrosive and abrasive environments

- Digital Integration: Implement Industry 4.0 technologies for predictive maintenance and performance optimization

- Regional Expansion: Strengthen distribution in emerging recycling markets

- Technical Partnerships: Collaborate with recycling machinery manufacturers for integrated solutions

Procurement professionals should prioritize:

- Lifecycle cost analysis rather than initial purchase price

- Application engineering support for optimal blade selection

- Supplier technical capabilities in heat treatment and precision grinding

- Material certification and performance guarantees

ShengAo's commitment to metallurgical excellence and manufacturing precision provides recycling operations with high-performance blade solutions that optimize processing efficiency and reduce total operational costs.

About ShengAo

ShengAo is a leading manufacturer of premium single-shaft shredder blades for plastic recycling applications. With expertise in advanced alloys (Cr12MoV, SKD-11, D2) and precision heat treatment, we deliver blades with optimal hardness (HRC 58-62) for efficient plastic shredding operations. Our commitment to quality, innovation, and customer satisfaction has established ShengAo as a trusted partner for recycling facilities worldwide.

For inquiries, please contact:

Engineer Jack

Email: jack@shenaozg.com

Mobile: +86 136 9673 1068

WhatsApp: +86 152 1234 9604

Address: Bowang town Songhua River road, Bowang District, Ma'anshan City, China