Premium Plastic Shredder Blades & Knives | Industrial-Grade for Recycling

Boost plastic recycling efficiency with our heavy-duty shredder blades and knives. Designed for industrial use, these durable blades ensure smooth operation and reduced downtime.

Get instant pricing and technical specifications for your project requirements

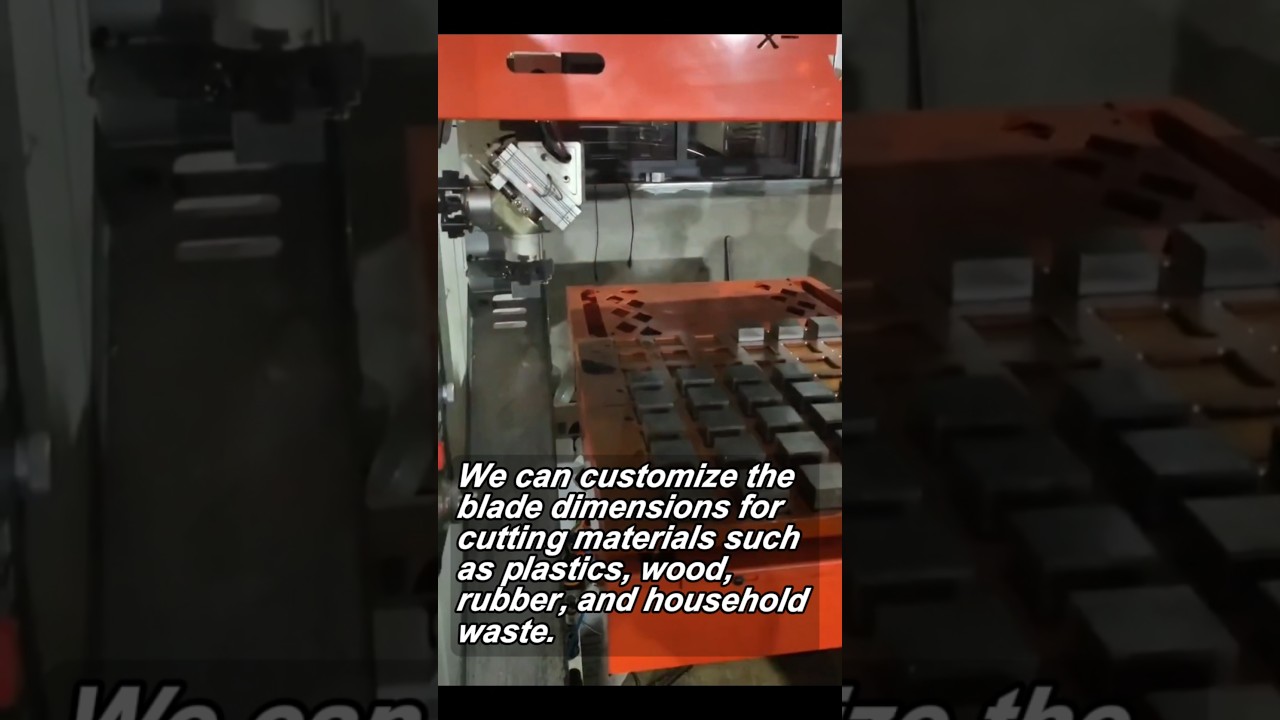

Product Video Demonstration

Product Specifications

| ShengAo Single-Axis Shredder Blades | Premium D2 Steel Blades | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Premium Plastic Shredder Blades & Knives | Industrial-Grade for Recycling Boost plastic recycling efficiency with our heavy-duty shredder blades and knives. Designed for industrial use, these durable D2 steel blades ensure smooth operation and reduced downtime. | ||||||||||

| Key Specifications | Product Name Single-axis shredder blade Material D2 Steel Spare Parts Type Shredder Blade Application Single-axis shredder Usage Cutting Brand Name ShengAo Place of Origin China Weight (KG) 0.25 Quality High-Quality OEM Service OEM Service Provided | |||||||||

| Quality & Certification | Inspection & Reports Machinery Test Report: Provided Video Outgoing-Inspection: Provided Warranty & Key Selling Points - Warranty: Unavailable D2 Key Selling Points: Shredder Machine Blades | |||||||||

| Order & Delivery | Minimum Order & Standard Delivery MOQ: 100pcs Delivery: Within 15-20 Working Days Standard Lead Time Quantity-Based Lead Time Details

Lead time starts from order confirmation and deposit received. OEM orders require additional negotiation. | |||||||||

Raw Materials & Alloys

Crafted from premium materials for exceptional performance and durability

About Our Single-Axis Shredder Blades

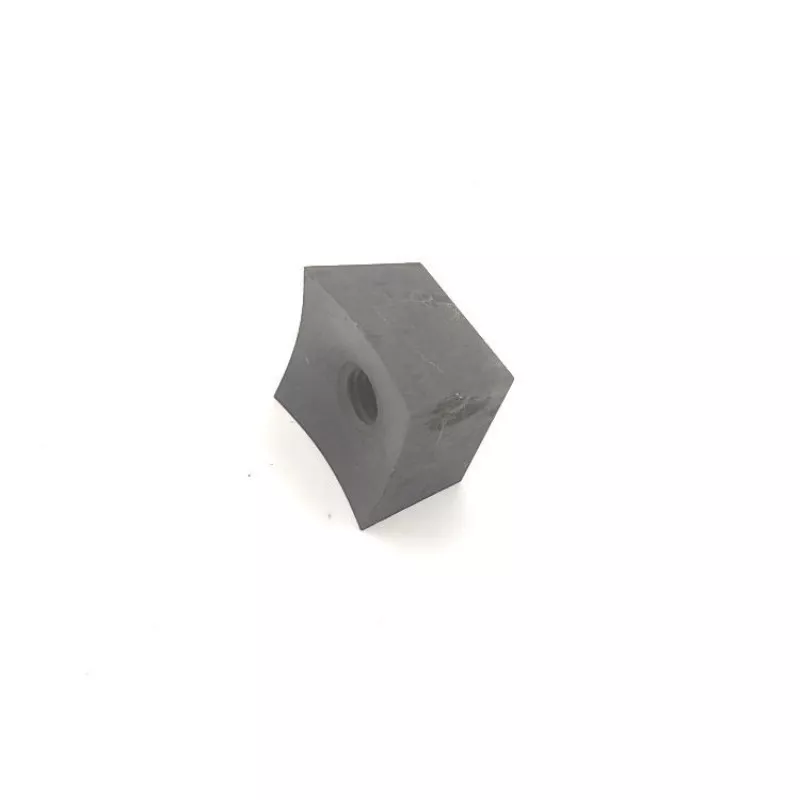

The single-axis shredder rotor blade and counter blade are the core components of industrial shredding systems, designed to efficiently reduce plastic materials for recycling, reprocessing, or disposal. Our premium single-axis shredder blades are engineered for maximum performance and durability in demanding industrial environments. These high-quality D2 steel blades are specifically designed to boost plastic recycling efficiency, ensure smooth operation, and minimize downtime, making them ideal for industrial-grade recycling operations.

Premium Material & Construction

Our single-axis shredder blades are manufactured from premium D2 steel, a high-carbon, high-chromium tool steel known for its exceptional wear resistance and ability to maintain sharp edges under demanding conditions. D2 steel provides superior hardness (typically HRC 58-62) and excellent dimensional stability, making it ideal for precision cutting applications. Each blade undergoes precision machining and specialized heat treatment to achieve optimal hardness and toughness. The blades feature high-precision grinding with burr-free surfaces for smooth operation and consistent cutting performance, ensuring reliable shredding output in continuous industrial operations.

Key Features & Operational Benefits

Engineered for long service life and reliable performance, these D2 steel shredder blades deliver significant operational advantages. Their exceptional wear resistance reduces maintenance frequency and extends intervals between blade changes, minimizing production downtime. The high hardness and edge retention ensure consistent cutting efficiency throughout the blade's lifecycle. With a weight of 0.25kg, each blade is designed for optimal balance and efficient operation in single-axis shredders. The robust construction provides high rigidity, preventing bending and deformation under heavy loads, ensuring stable shredding output and reduced energy consumption in industrial plastic recycling operations.

Application Industries & Materials

These single-axis shredder blades are specifically designed for plastic recycling and processing applications across multiple industries. They excel in processing plastic bottles (PET, HDPE), plastic films (LDPE, LLDPE), hard plastics (PP, ABS, PC), plastic lumps and purgings, plastic pipes and profiles, and various other recyclable plastic materials. Key industries that rely on their performance include plastic recycling plants, packaging material manufacturers, waste management facilities, plastic product manufacturers, and material recovery operations. Designed specifically for cutting applications in single-axis shredders, these blades provide reliable, high-efficiency size reduction for transforming plastic waste into recyclable materials.

Customization & Quality Assurance

We specialize in providing customized blade solutions with comprehensive OEM service support. While our standard blades are made from premium D2 steel, we can customize dimensions, hole patterns, and other specifications to fit your specific single-axis shredder model. Our commitment to quality is demonstrated through comprehensive verification: we provide both machinery test reports and video outgoing-inspection for every order, ensuring transparent quality assurance. Although warranty is not available for this product line, our rigorous manufacturing processes and quality controls ensure consistent performance and reliability. We offer standard lead times of 15 days for 1-100 pieces with a minimum order quantity of 100 pieces for custom orders, ensuring efficient production scheduling for industrial customers.

Top 5 Industrial Shredder Blade Manufacturers

Choosing the right manufacturer for industrial shredder blades is crucial for achieving optimal shredding efficiency, minimal downtime, and reliable performance. These companies are recognized for their material expertise, engineering capabilities, and quality manufacturing processes.

ShengAo

A leading manufacturer specializing in high-performance single-axis shredder blades made from premium D2 steel. Their blades are engineered for exceptional wear resistance, long service life, and high cutting efficiency in plastic recycling applications. Key advantages include comprehensive quality assurance (machinery test reports, video inspection), OEM service support, competitive pricing with MOQ of 100 pieces, and fast 15-day lead times for standard orders. Recognized for providing durable, high-quality blade solutions that enhance productivity in industrial plastic recycling and shredding operations.

Vecoplan

A German global leader in shredding technology, Vecoplan manufactures high-quality shredder blades known for innovative designs, durability, and precision engineering. Their blades are used in various industrial applications including plastic recycling, wood processing, and waste management.

SSI Shredding Systems

An American manufacturer with global presence, SSI designs and produces heavy-duty shredder blades for industrial applications, focusing on durability, reliability, and performance in demanding environments like plastic recycling and waste processing.

WEIMA

A German manufacturer of shredding and briquetting systems, WEIMA produces durable shredder blades focused on energy efficiency, low-noise operation, and high throughput for processing plastics, wood, and other materials in industrial applications.

Rapid Granulator

A Swedish world leader in granulation technology, Rapid manufactures precision shredder and granulator blades focusing on clean cutting action, consistent particle size, and energy efficiency for plastic recycling and processing applications.

Frequently Asked Questions (FAQs)

Find expert answers to common questions about ShengAo Single-Axis Shredder Blades with D2 Steel construction for industrial plastic recycling applications.