Premium Double Shaft Shredder Blades | High-Performance Industrial Shredder Blades

Boost your shredding output with our high-quality double-shaft industrial shredder blades. Engineered for durability on plastic, metal, tires.

Get instant pricing and technical specifications for your project requirements

Product Video Demonstration

Product Specifications

| Premium Double Shaft Shredder Blades | High-Performance Industrial Shredder Blades | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

High-Performance Industrial Double Shaft Shredder Blades Boost your shredding output with our high-quality double-shaft industrial shredder blades. Engineered for durability on plastic, metal, tires. | ||||||||||

| Key Attributes | Brand Name ShengAo Place of Origin Anhui, China Core Components Blade Machinery Test Report Provided Video Outgoing-Inspection Provided Warranty 3 Months | |||||||||

| Delivery Information | Quantity-Based Lead Time

Lead time starts from order confirmation and deposit received. | |||||||||

Raw Materials & Alloys

Crafted from premium materials for exceptional performance and durability

About Our Premium Double Shaft Shredder Blades

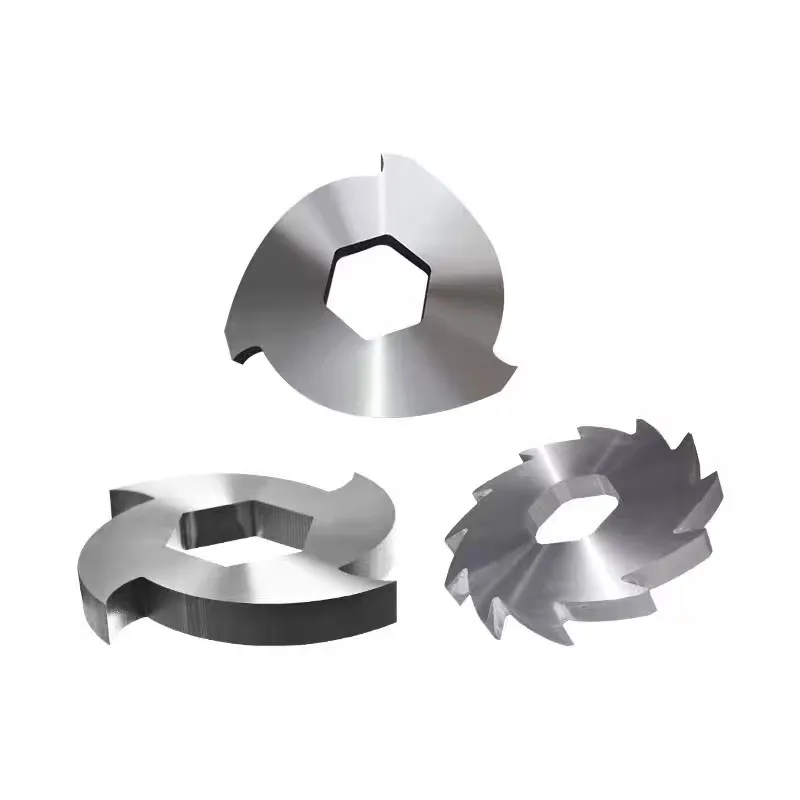

Double shaft shredder blades are precision-engineered cutting components designed for industrial size reduction applications. Featuring two counter-rotating shafts with intermeshing blades, these systems provide superior cutting power, consistent particle size, and high throughput for challenging materials. Our custom-made double shaft shredder blades are engineered for maximum performance, durability, and efficiency in demanding industrial recycling environments.

Premium Material & Construction

Our double shaft shredder blades are manufactured from premium tool steel alloys including D2, DC53, 6CrW2Si, and other high-grade materials, selected for their exceptional wear resistance, toughness, and durability. These materials ensure high hardness (typically 58-62 HRC) and impact resistance, making the blades ideal for shredding challenging materials like metals, tires, and hard plastics. Each blade undergoes precision machining and heat treatment to achieve optimal performance characteristics, featuring high-precision cutting edges and burr-free surfaces for smooth operation and consistent cutting performance.

Key Features & Benefits

Designed for extended service life in demanding industrial environments, these double shaft shredder blades deliver exceptional operational benefits. Their wear-resistant properties significantly reduce downtime for blade changes and maintenance, maximizing equipment uptime and productivity. The intermeshing design provides superior cutting action and consistent particle size output. With comprehensive quality documentation including machinery test reports and video outgoing-inspection, you receive verified quality. The robust construction ensures high cutting efficiency and stable processing output over extended production runs, making them ideal for continuous industrial operations.

Application Industries & Materials

These high-performance double shaft shredder blades are engineered for a wide range of industrial size reduction applications. They are highly effective in processing plastic waste (hard plastics, lumps, films), metals (light gauge, aluminum, non-ferrous), tires (car, truck), rubber, wood, and other industrial materials. Industries that benefit most include plastic recycling facilities, metal processing plants, tire recycling operations, electronic waste processors, automotive shredding, and general industrial waste management. The dual-shaft design provides increased torque and cutting power for processing tough, bulky, or mixed material streams efficiently.

Customization & Quality Assurance

We specialize in providing tailor-made double shaft shredder blade solutions. Every aspect can be customized, including blade dimensions, cutting edge geometry, material selection, and specialized configurations for specific applications. Our commitment to quality is demonstrated through comprehensive documentation including both machinery test reports and video outgoing-inspection provided with every order, offering complete verification of blade quality and specifications. We back our products with a solid 3-month warranty covering manufacturing defects. With competitive lead times (15 days for 1-10 pieces) and full customization capabilities, we provide practical, high-performance solutions for industrial double shaft shredding operations worldwide.

Top 5 Double Shaft Shredder Blade Manufacturers

Selecting the right manufacturer for double shaft shredder blades is crucial for achieving optimal shredding efficiency, minimal downtime, and cost-effective operation in plastic, metal, tire, and industrial material processing. These brands are recognized for their material expertise, precision engineering, and proven performance in demanding double shaft shredding applications.

ShengAo

A leading manufacturer specializing in high-performance double shaft shredder blades for industrial recycling applications. Based in Anhui, China, ShengAo is recognized for its premium tool steel materials (D2, DC53, 6CrW2Si), precision engineering, and exceptional durability. Key advantages include comprehensive machinery test reports and video outgoing-inspection for quality verification, a solid 3-month warranty, competitive lead times (15 days for small orders), and full support for customized specifications. Their blades are engineered for maximum efficiency and longevity in demanding double shaft shredding operations worldwide.

Vecoplan

A German manufacturer of advanced recycling technology and shredding equipment, including robust double shaft shredders and replacement blades. Vecoplan produces high-quality double shaft shredder blades known for precision engineering, durability, and compatibility with their equipment and other industrial shredders for processing MSW, industrial waste, plastics, and wood globally.

SSI Shredding Systems

An American industrial shredder manufacturer known for durable equipment and replacement parts, including double shaft systems. SSI produces robust blades designed for various materials and applications, with a focus on system integration and reliable performance in demanding North American and international recycling markets.

Weima

A German manufacturer of shredding and briquetting equipment, including double shaft shredders. Weima produces durable double shaft shredder blades designed for various materials including plastics, wood, paper, and general waste. Their blades are known for good wear resistance and compatibility with different double shaft shredder models in the recycling industry.

Granutech-Saturn Systems

A global manufacturer of size reduction and recycling equipment, including double shaft shredders. They offer a range of double shaft shredder blades designed for processing various materials, including plastics, tires, metals, and general waste. Their products are built for reliability in continuous industrial operations worldwide.

Frequently Asked Questions (FAQs)

Find expert answers to common questions about ShengAo Premium Double Shaft Shredder Blades for industrial plastic recycling, metal processing, tire shredding, and material size reduction applications.