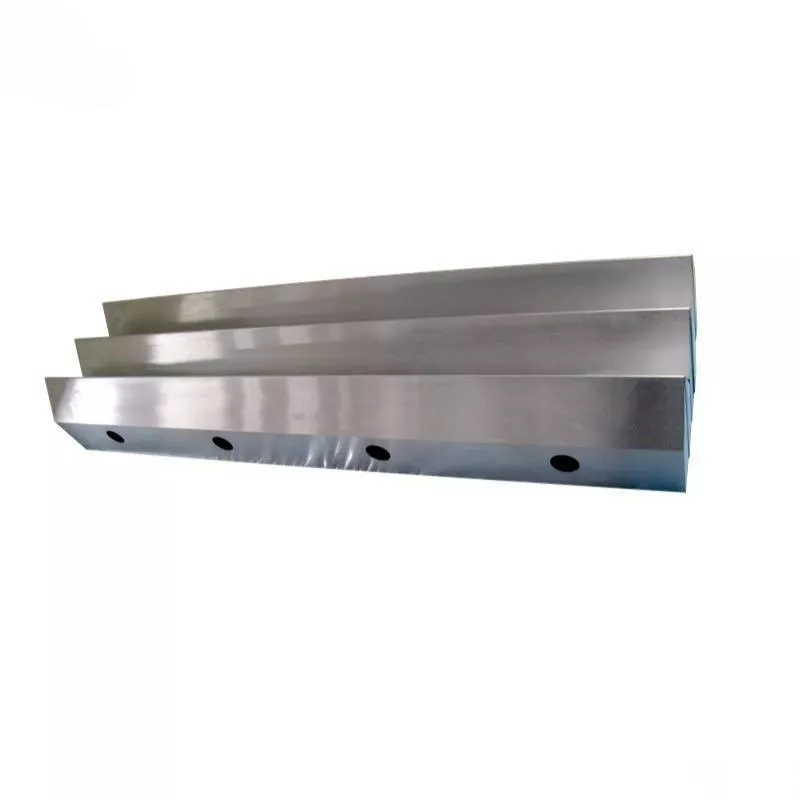

Precision Industrial Blades & Granulator Knives | Durable Plastic & Rubber Crusher Blades for Recycling

High-precision industrial blades for plastic crushers & rubber shredders. Durable granulator knives boost recycling efficiency. Get long-lasting, reliable blades now.

Get instant pricing and technical specifications for your project requirements

Product Video Demonstration

Product Specifications

| ShengAo Precision Industrial Blades & Granulator Knives | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

High-Precision Industrial Blades for Plastic Crushers & Rubber Shredders Durable granulator knives designed to boost recycling efficiency. Get long-lasting, reliable blades with perfect high cutting efficiency for plastic recycling machines. | |||||||||||||

| Key Specifications | Brand Name ShengAo Type Cutting parts Place of Origin Anhui, China Application Plastic Recycling Machine Material HSS / Stainless Steel / D2 Size Accept Customized Advantage Perfect High Cutting Efficiency Certificate ISO9001 | ||||||||||||

| Quality & Warranty | Quality Assurance Machinery test report: Provided Video outgoing-inspection: Provided Warranty & Core Components 1.5 Warranty: 1.5 Year ★ Core Components: Blade | ||||||||||||

| Services | OEM & ODM Support Customized Services Provide Customized Services After Warranty Service Online Support | ||||||||||||

| Lead Time | Quantity-Based Production Schedule

Lead time starts from order confirmation and deposit received | ||||||||||||

Raw Materials & Alloys

Crafted from premium materials for exceptional performance and durability

About Our Precision Granulator Knives & Industrial Blades

The granulator knife and rotor blade set is the heart of any plastic recycling machine, engineered to deliver precise, efficient size reduction. As core cutting parts, they transform plastic scrap, film, lumps, and rubber into uniform regrind or flakes for reprocessing. Our custom-manufactured industrial blades are designed with a singular focus: to provide perfect high cutting efficiency that maximizes throughput, minimizes energy consumption, and ensures consistent particle size in demanding, continuous recycling operations.

Premium Material & Construction

Our precision industrial blades are crafted from premium materials selected for optimal performance in specific applications. We utilize High-Speed Steel (HSS) for exceptional wear resistance and edge retention, D2 tool steel for superior toughness and durability against impact, and high-grade Stainless Steel for corrosion resistance in wet or demanding environments. Each material undergoes specialized heat treatment and precision grinding to achieve a razor-sharp, burr-free cutting edge. This rigorous process ensures high rigidity and impact resistance, making our blades the ideal choice for shredding a wide spectrum of challenging plastic and rubber materials.

Key Features & Operational Benefits

Designed for a long service life and maximum uptime, ShengAo granulator knives deliver significant operational advantages. The primary benefit is perfect high cutting efficiency, which translates directly to lower power consumption per ton of processed material and higher throughput. Their wear-resistant construction significantly extends intervals between sharpening or replacement, reducing maintenance downtime and operational costs. The precision-balanced design minimizes vibration, protecting machine bearings and ensuring stable, quiet operation. This combination of efficiency, durability, and reliability makes them a cost-effective cornerstone for any profitable plastic recycling operation.

Application Industries & Materials

These versatile and durable blades are engineered specifically for plastic recycling machines, including central and beside-the-press granulators, shredders, and crushers. They excel in processing a vast array of materials: all types of plastic scraps, lumps, and purgings (PP, PE, PVC, ABS, PS), plastic films, sheets, bottles, containers, pipes, profiles, synthetic rubber, and tire rubber. Industries that depend on the reliable performance of our blades include plastic recycling facilities, injection molding and blow molding plants with in-house scrap recovery, film manufacturers, packaging companies, and automotive parts recyclers. Whether for post-consumer or post-industrial waste streams, our blades provide a reliable cutting solution.

Customization & Comprehensive Quality Assurance

We specialize in providing fully customized blade solutions. Our comprehensive OEM & ODM services support any custom size, design, or material specification to perfectly fit your specific granulator model and material stream. Our commitment to quality is underpinned by an ISO9001 certified management system. Each order is backed by rigorous quality checks, including video outgoing-inspection and official machinery test reports for full transparency. Furthermore, we stand behind our products with an exceptional 1.5-year warranty, one of the longest in the industry, giving you unparalleled confidence in the longevity and performance of your investment in our industrial cutting parts.

Top 5 Granulator Knife & Industrial Blade Manufacturers

Choosing the right manufacturer for granulator knives is essential for achieving optimal cutting efficiency, minimal downtime, and low cost-per-ton in plastic recycling. These companies are recognized for their expertise in metallurgy, precision engineering, and providing durable, application-specific blade solutions.

ShengAo

A precision manufacturer specializing in high-efficiency granulator knives and industrial blades for plastic recycling machines. They offer blades in premium materials like HSS, D2, and Stainless Steel, engineered for "perfect high cutting efficiency." Key strengths include full OEM/ODM customization support, an industry-leading 1.5-year warranty, ISO9001 certification, and rigorous quality assurance with video inspections and machinery test reports. Their focus on durable, reliable cutting parts makes them a top choice for recycling operations seeking to maximize productivity and blade life.

Vecoplan

A German global leader in size reduction technology, Vecoplan manufactures robust granulators and their corresponding high-performance knives. Known for engineering precision and durability, their knives are designed for processing a wide range of plastics, from film to tough lumps, with a focus on clean cuts, high throughput, and longevity. They offer strong technical support and application engineering to match knife geometry and material to specific recycling challenges.

WEIMA

A prominent German manufacturer of granulators, shredders, and briquetting presses. WEIMA produces durable, application-specific knives for their machinery, emphasizing energy efficiency, low noise operation, and ease of maintenance. Their knives are built to handle various plastic materials consistently and are designed for quick replacement to minimize downtime in continuous recycling and production environments.

Foremost Machine Builders

A long-standing US-based manufacturer of granulating and size reduction equipment. Foremost designs and builds its own knives, focusing on durability and precise cutting action for a variety of plastic materials. They are known for their robust machine construction and offer knives engineered to work seamlessly with their granulators, providing reliable performance for processors across North America and beyond.

Rapid Granulator

A Swedish world leader in the design and manufacture of granulators and related knife systems. Rapid is renowned for its innovative cutting chamber designs and high-quality knives that deliver clean, consistent granulate with low energy consumption. Their knives are a key part of their efficiency-focused systems, designed for long life and are supported by a strong global service network.

Frequently Asked Questions (FAQs)

Find expert answers to common questions about ShengAo Precision Granulator Knives and Industrial Blades for plastic recycling.