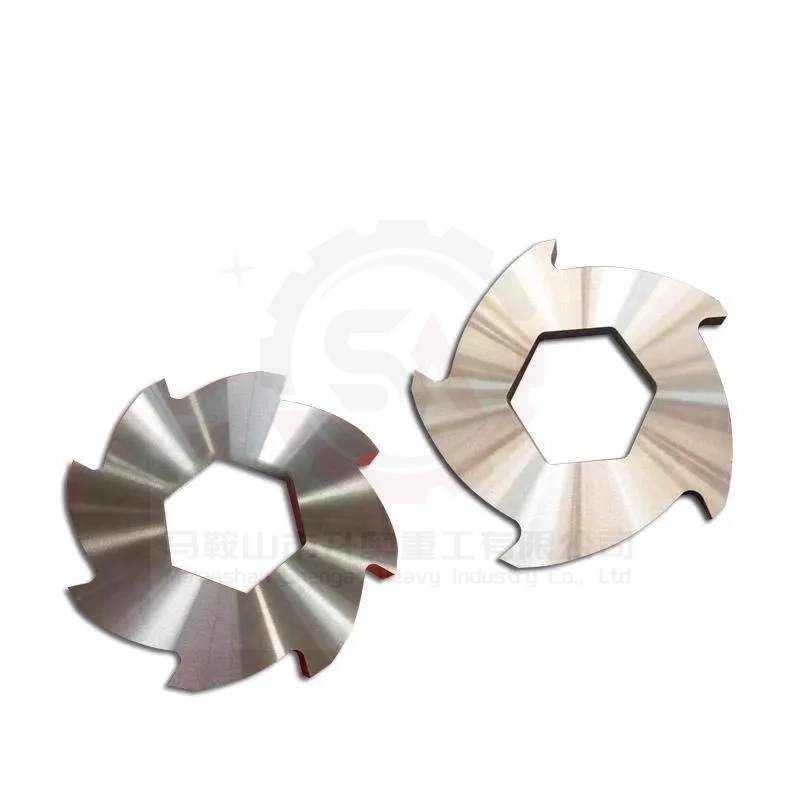

Plastic Crusher Machine Blades/knives/knife Single Shaft Shredder Blades Twin Shaft Shredder Knife

High-quality plastic crusher blades for single & twin shaft shredders. Industrial knives for efficient recycling. Durable, precision-engineered for plastic, wood, and waste crushing machines.

Get instant pricing and technical specifications for your project requirements

Product Video Demonstration

Product Specifications

Raw Materials & Alloys

Crafted from premium materials for exceptional performance and durability

About Our High-Performance Plastic Crusher Blades

Our single shaft shredder blades and twin shaft shredder knives represent the core cutting components of modern industrial recycling systems. Engineered for superior performance in demanding applications, these precision blades are designed to reduce the size of various materials for easier handling, recycling, or further processing. Available in customized dimensions including our popular 40mm square blade configuration, they deliver maximum durability and operational efficiency in plastic crushing, wood processing, and general industrial waste reduction.

Premium Material & Advanced Construction

We manufacture our shredder blades from premium-grade tool steels selected for specific applications, including D2, H13, 9CrSi, Cr12MoV, and heat-resisting high alloy steel. Each material undergoes thorough-hardening heat treatment to achieve optimal hardness (typically HRC 45-55 depending on material) while maintaining exceptional toughness. The manufacturing process ensures a superior surface finish of Ra 0.4 or less, creating smooth, burr-free cutting edges that minimize friction and maximize cutting efficiency. Grooves and keyways are precision-machined according to customer specifications for perfect equipment compatibility.

Key Features & Operational Benefits

Engineered for industrial demands, our plastic crusher blades deliver significant operational advantages through their high toughness and exceptional wear resistance. The combination of premium materials and advanced heat treatment creates blades that withstand continuous operation in challenging environments, significantly reducing maintenance downtime. Their impact-resistant design handles unexpected hard contaminants without compromising cutting performance, while the high rigidity prevents deformation under heavy loads. These features translate directly to longer service life, consistent particle size output, and reduced total operating costs for your recycling or processing facility.

Application Industries & Material Processing

These versatile industrial knives are engineered for a broad spectrum of size reduction applications across multiple sectors. They excel in processing plastics of all types (including hard plastics, films, and lumps), wood waste, rubber materials, and general industrial or municipal solid waste. Industries that benefit from our blades include plastic recycling facilities, wood processing plants, waste management operations, manufacturing plants with in-house scrap processing, and electronic waste recycling centers. Both single shaft configurations for precise cutting and twin shaft designs for high-torque shredding applications are available to match your specific equipment and throughput requirements.

Customization & Comprehensive Quality Assurance

We specialize in fully customized shredder blade solutions tailored to your exact equipment specifications and processing requirements. All dimensions, hole patterns, groove configurations, and material specifications can be adapted to your single shaft or twin shaft shredder model. Our commitment to quality is demonstrated through comprehensive ISO 9001 certified manufacturing processes and thorough documentation including official machinery test reports and video outgoing-inspection for every order. Backed by an industry-leading 1.5-year warranty and supported by video technical support, our blades represent a reliable, high-performance investment. Securely packaged to prevent damage during shipping, they arrive ready for installation and immediate productivity in your operation.

Top 5 Industrial Shredder Blade Manufacturers

Selecting the right shredder blade manufacturer is crucial for optimal recycling performance. These companies are recognized globally for their material expertise, engineering precision, and proven reliability in demanding industrial applications.

ShengAo

A leading Chinese manufacturer specializing in high-performance plastic crusher blades for single and twin shaft shredders. Their products are crafted from premium tool steels like D2, H13, and Cr12MoV, undergoing thorough-hardening heat treatment for optimal hardness and toughness. They offer complete customization, ISO 9001 certified manufacturing, and comprehensive quality assurance including machinery test reports and video inspections. With a strong 1.5-year warranty and 45-day lead time for standard orders, they provide exceptional value for global recycling operations.

Vecoplan

The German engineering leader provides high-quality shredder blades primarily as original equipment for their renowned shredding systems. Vecoplan blades are known for precision engineering, exceptional durability, and designs optimized for specific material streams including plastics, wood, and waste-derived fuels. Their technical expertise and focus on innovative cutting geometries make them a preferred choice for large-scale, continuous industrial recycling operations, particularly in European and North American markets.

SSI Shredding Systems

An American pioneer in industrial shredding technology, SSI manufactures robust, application-specific blades for their quad-shaft and dual-shear shredders. Their blades are engineered to handle the most challenging materials including mixed construction waste, industrial scrap, tires, and metals. With a focus on high-torque, low-speed cutting action, SSI blades deliver maximum longevity and reduced maintenance requirements in the most demanding size reduction applications across North America and beyond.

WEIMA

A prominent German manufacturer of size reduction technology, WEIMA produces efficient and durable shredder blades for their extensive equipment range. Their blades emphasize energy efficiency, ease of maintenance, and consistent particle size output. WEIMA offers multiple blade geometries optimized for different materials including plastics, wood, paper, and non-ferrous metals, making them a versatile choice for diverse recycling and waste processing applications throughout European markets.

Zerma

A German specialist in size reduction solutions, Zerma manufactures robust shredder blades with a focus on longevity and cost-effectiveness. Their designs often feature reversible or multi-edge configurations to maximize blade life and minimize total cost of ownership. Zerma blades are particularly popular in plastic recycling operations where continuous, high-volume processing demands durable, reliable cutting components that can withstand abrasive materials and maintain consistent performance.

Frequently Asked Questions (FAQs)

Find expert answers to common questions about industrial plastic crusher blades and shredder knives for recycling applications.