OEM Tungsten Carbide Industrial Blade Plastic Recycling Shredder Knife

OEM Tungsten Carbide blades for plastic recycling shredders. High wear resistance, extended service life for industrial plastic shredding. Custom solutions available.

Get instant pricing and technical specifications for your project requirements

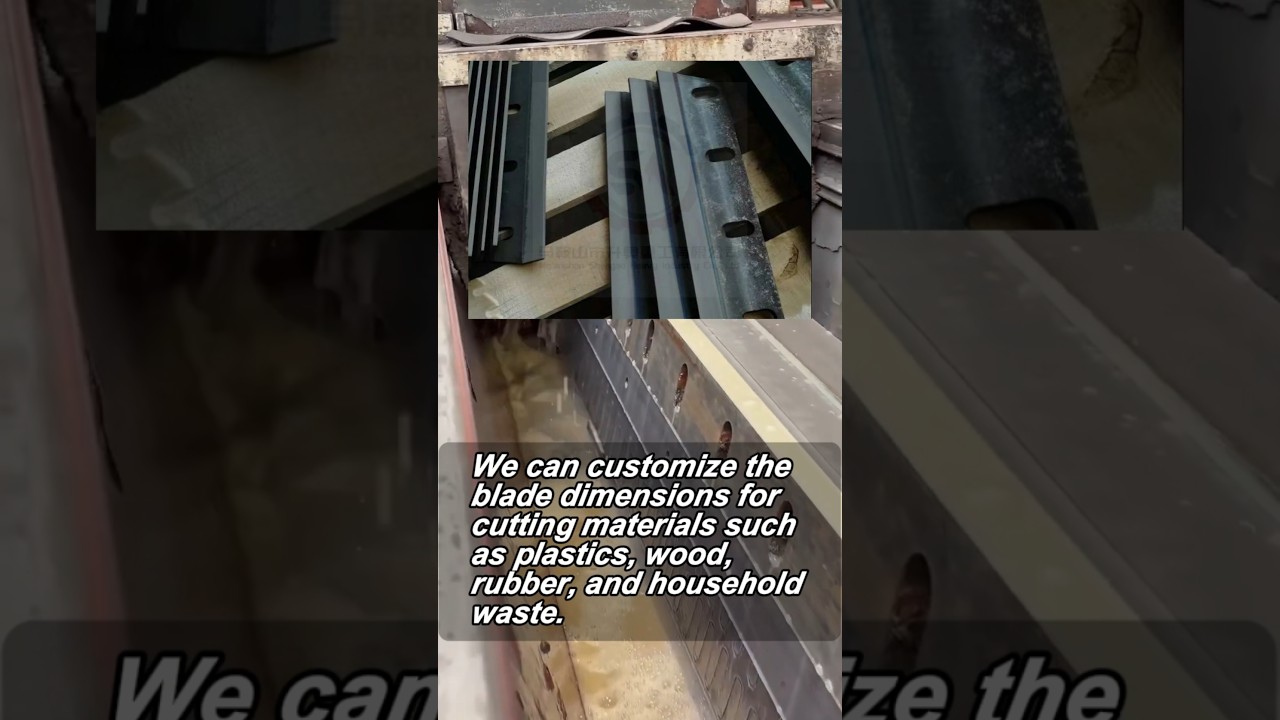

Product Video Demonstration

Product Specifications

| ShengAo OEM Tungsten Carbide Industrial Blades | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

OEM Tungsten Carbide Industrial Blade Plastic Recycling Shredder Knife OEM Tungsten Carbide blades for plastic recycling shredders. High wear resistance, extended service life for industrial plastic shredding. Custom solutions available. | ||||||||||

| Key Attributes | Brand Name ShengAo Type Cutting parts Place of Origin Anhui, China Primary Application Industrial photovoltaic panel edge trimming Customization Blade for customization available Also Known As • Edge trimming industrial blade • Industrial blade for photovoltaic panel trimming | |||||||||

| Quality Assurance | Quality Control Documents Machinery test report: Provided Video outgoing-inspection: Provided Warranty & Core Components 3 Warranty: 3 Years P Core Components: Plastic | |||||||||

| Lead Time & Delivery | Quantity-Based Lead Time

Note: Lead time starts from order confirmation and deposit received. Customization options may affect lead time. | |||||||||

Raw Materials & Alloys

Crafted from premium materials for exceptional performance and durability

About Our Tungsten Carbide Industrial Blades

Our tungsten carbide industrial blades represent the pinnacle of cutting technology for demanding industrial applications. As OEM-specification cutting parts, these blades are engineered to deliver exceptional performance in two critical areas: industrial photovoltaic panel edge trimming and high-wear plastic recycling shredding. Manufactured with precision and durability at their core, these blades are designed to meet the exacting standards of modern manufacturing and recycling operations, providing consistent, reliable cutting performance in environments where failure is not an option.

Premium Material & Construction

At the core of these industrial blades is tungsten carbide (WC), a material renowned for its extreme hardness, exceptional wear resistance, and ability to maintain a sharp cutting edge far longer than conventional tool steels. The carbide tips are precision-brazed or mechanically secured to a durable steel body, providing the perfect combination of cutting-edge performance and structural integrity. Each blade undergoes meticulous grinding and finishing to achieve a razor-sharp, burr-free edge with exacting tolerances, ensuring clean cuts, minimal material waste, and smooth operation in both automated solar panel production lines and heavy-duty shredding machines.

Key Features & Operational Benefits

Engineered for longevity and peak efficiency, these tungsten carbide blades deliver unparalleled benefits. Their primary advantage is extraordinary wear resistance, which translates directly into an extended service life that can be 10 to 20 times longer than standard steel blades. This dramatically reduces the frequency of blade changes, minimizing costly downtime in continuous production or recycling processes. The blades' inherent hardness ensures consistent cutting quality over their entire lifespan, producing clean, precise edges on photovoltaic panels or uniform shreds in plastic recycling. This reliability protects your investment and maximizes operational uptime and output quality.

Application Industries & Materials

These versatile, high-performance blades are designed for two primary, demanding sectors. In the renewable energy industry, they are the go-to solution for industrial photovoltaic panel edge trimming, cleanly cutting through laminated glass, EVA encapsulant, backsheets, and silicon wafers with precision. In the waste management and recycling industry, they excel as plastic recycling shredder knives, effectively processing highly abrasive materials like fiberglass-reinforced plastics (FRP), engineering thermoplastics, film, and post-consumer plastic waste. This dual applicability makes them essential for manufacturers of solar panels and operators of advanced plastic recycling facilities who demand the longest possible blade life and consistent cut quality.

Customization & Comprehensive Quality Assurance

We specialize in providing fully customized OEM tungsten carbide blade solutions. From the specific grade of carbide (grain size, cobalt binder percentage) to the exact blade dimensions, edge geometry, and mounting configuration, every detail can be tailored to fit your specific machinery and material. Our commitment to quality is absolute and transparent. Each order is backed by an industry-leading 3-year warranty and supported with comprehensive documentation including official machinery test reports and detailed video outgoing-inspection footage. This rigorous process ensures you receive a premium product that meets your exact specifications, providing peace of mind and a reliable cutting solution built for endurance and performance.

Top 5 Industrial Shredder & Precision Cutting Blade Manufacturers

Choosing the right manufacturer for high-wear industrial blades is critical for maximizing productivity and minimizing downtime. These companies are recognized for their expertise in advanced materials like tungsten carbide and their ability to deliver precision, durability, and custom engineering.

ShengAo

A leading specialist in OEM tungsten carbide industrial blades for niche and demanding applications. Their expertise spans industrial photovoltaic panel edge trimming blades and high-wear plastic recycling shredder knives. They offer fully customized solutions using premium tungsten carbide grades, ensuring extreme wear resistance and long service life. Backed by a robust 3-year warranty and comprehensive quality assurance including machinery test reports and video inspections, they provide reliable, high-performance cutting solutions with a standard 15-day lead time for orders up to 50 pieces.

Kennametal

A global giant in engineered components and advanced materials, Kennametal offers a wide range of tungsten carbide cutting tools, including inserts and blades for industrial machining and size reduction. They are known for their metallurgical expertise, extensive R&D, and standard catalog offerings for various industrial cutting applications, providing reliable solutions for general-purpose use.

Sandvik

Sandvik's materials technology division produces high-quality cemented carbide products. They supply premium carbide grades and standardized cutting inserts used in various industries, including metalworking and wood processing. Their strength lies in consistent material quality and a deep understanding of wear-resistant materials for machining applications.

Iscar

A leading manufacturer of carbide metalworking tools, Iscar offers innovative insert geometries and grades. While focused primarily on metal cutting, their expertise in carbide extends to specialized applications. They are known for innovative tool designs that improve efficiency and chip control in machining operations.

Mitsubishi Materials

A Japanese multinational offering a comprehensive range of cutting tools and carbide products. They provide high-quality carbide inserts and tools for various industries, known for precision and reliability. Their products are often used in demanding, high-precision manufacturing environments.

Frequently Asked Questions (FAQs)

Find expert answers to common questions about Tungsten Carbide Industrial Blades for photovoltaic panel trimming and plastic recycling.