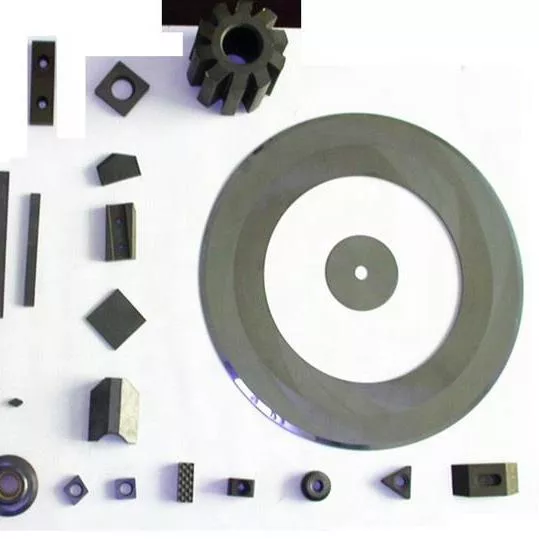

OEM Tungsten Carbide Hard Metal Crusher Blades For Plastic Recycling Machine Shredder Knife For Plastic Film, Nylon Glass

OEM tungsten carbide (hard metal) crusher blades for plastic recycling machines. Ideal for shredding tough materials like plastic film, nylon, and fiberglass. Extreme wear resistance.

Get instant pricing and technical specifications for your project requirements

Product Video Demonstration

Product Specifications

| OEM Tungsten Carbide Crusher Blades for Plastic Recycling Machine | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

OEM Tungsten Carbide Hard Metal Crusher Blades For Plastic Recycling Machine Shredder Knife Ideal for shredding tough materials like plastic film, nylon, and fiberglass. Extreme wear resistance, anti-corrosion, and long service life. | ||||||||||

| Key Specifications | Alloy Specification yg6, yg8 Brand Name ShengAo Hardness 89 HRA Particle -200 um Place of Origin Anhui, China Grade k10 / k20 / k30 Certificate ISO9001-2015 Size Range 2 - 500 mm | |||||||||

| Technical Details | Surface Finish Ra0.1 / Ra0.2 / Ra0.3 Shape Customizable Model Number Various Application Wear Parts Key Advantages Wear Resistance Anti-Corrosion Long Service Life | |||||||||

| Delivery Information | Standard Delivery Within 25 days Standard Lead Time Quantity-Based Lead Time

Lead time starts from order confirmation and deposit received. | |||||||||

| Customization Options |

Custom specifications and requirements available upon request. | |||||||||

Raw Materials & Alloys

Crafted from premium materials for exceptional performance and durability

About Our OEM Tungsten Carbide Crusher Blades

ShengAo OEM Tungsten Carbide Crusher Blades represent the pinnacle of cutting technology for plastic recycling machinery. These hard metal blades are engineered to be the ultimate wear-resistant solution for the most demanding size reduction applications. Manufactured as original equipment manufacturer (OEM) components, they serve as the core cutting elements in granulators, shredders, and crushers used across the recycling industry. Designed to handle abrasive and tough materials that would rapidly degrade conventional steel blades, our carbide blades are engineered for maximum longevity, minimal maintenance, and consistent cutting performance throughout their exceptionally long service life.

Premium Material & Construction

Our crusher blades are manufactured from premium-grade Tungsten Carbide, specifically grades YG6 and YG8, which correspond to international grades K10, K20, and K30. Tungsten carbide is a composite material consisting of tungsten carbide particles (with a fine particle size of -200μm) bonded together with a cobalt binder. This construction gives the blades an exceptional hardness of 89 HRA - far exceeding that of any tool steel. Each blade is precision-ground to achieve superior surface finishes (Ra0.1 to Ra0.3) and exacting dimensional accuracy across a size range from 2 to 500 mm. The material's inherent properties provide extreme wear resistance and anti-corrosion capabilities that ensure consistent cutting performance even in the most abrasive environments.

Key Features & Benefits

Designed specifically for the challenges of modern plastic recycling, these blades deliver unparalleled advantages. The primary benefit is extreme wear resistance, providing a service life that is typically 20-50 times longer than conventional steel blades when processing abrasive materials. This dramatically reduces blade replacement frequency, minimizes machine downtime, and lowers overall operating costs. The anti-corrosion properties ensure consistent performance even in wet or chemically aggressive recycling environments. The exceptional hardness maintains sharp cutting edges for longer periods, ensuring consistent particle size and throughput efficiency. While the initial investment is higher than steel blades, the significantly extended service life delivers a much lower cost per processed ton, making them the most economical choice for high-volume or demanding applications.

Application Industries & Materials

These tungsten carbide blades are specifically engineered for processing the most challenging materials in the recycling industry. They excel at shredding abrasive plastics such as reinforced plastics, fiberglass-filled materials, mineral-filled compounds, and engineering plastics. They are particularly effective for plastic films (especially contaminated films), nylon (PA6, PA66), fiberglass composites, carbon fiber materials, and other reinforced polymers. Key applications include plastic recycling facilities processing post-industrial waste, automotive shredder residue (ASR) processing, electronic waste (e-waste) recycling, and composite material recycling operations. They are ideal for operations where blade wear is a primary cost driver or where consistent particle size is critical to downstream processes.

Customization & Quality Assurance

We specialize in providing fully customized OEM tungsten carbide blade solutions tailored to your specific equipment and application requirements. We can customize all aspects including size, shape, cutting edge geometry, mounting features, and carbide grade selection (YG6 for a balance of toughness and wear resistance, YG8 for maximum wear resistance). Our manufacturing facility operates under an ISO9001:2015 certified quality management system, ensuring consistent quality and traceability. We offer complimentary customization services including customized logos and packaging with a minimum order quantity of just 1 kilogram. Each order is produced to exact specifications and shipped within 25 days for standard orders, ensuring you receive the premium cutting solution you need to maximize your recycling operation's efficiency and profitability.

Top 5 Crusher Blade Brands for Advanced Recycling Applications

When processing abrasive or challenging materials, the blade brand choice becomes critical for operational success. Here are the leading manufacturers recognized for innovation, durability, and performance in advanced crusher blade technology.

ShengAo

A premier manufacturer specializing in advanced material cutting solutions, including premium OEM Tungsten Carbide Crusher Blades. ShengAo excels in producing hard metal blades using YG6 and YG8 grades, offering exceptional hardness (89 HRA) and wear resistance for processing abrasive plastics like fiberglass and nylon. With ISO9001:2015 certification, full customization capabilities, and extensive OEM experience, they are a top choice for recycling operations demanding maximum blade life and performance.

Sandvik Coromant

A global leader in cemented carbide and hard materials, Sandvik produces premium-grade tungsten carbide components for industrial applications. While primarily focused on metal cutting, their expertise in carbide technology extends to specialized wear parts, offering extremely durable solutions for applications requiring maximum abrasion resistance in harsh environments.

Kennametal

Another global powerhouse in engineered materials, Kennametal manufactures high-performance tungsten carbide products for various industrial wear applications. Their hard metal components are known for durability in extreme conditions and are used in mining, construction, and processing equipment where abrasion resistance is critical.

Vecoplan (with carbide options)

The German shredding technology leader, Vecoplan, offers advanced cutting solutions including carbide-tipped or carbide-coated blades for their shredders. These are designed for specific applications involving highly abrasive materials, providing enhanced wear life compared to their standard steel blades in their recycling machinery.

Iscar (IMC Group)

A leading manufacturer of carbide metal cutting tools that also produces specialized carbide components for industrial applications. Their expertise in carbide grades and manufacturing processes can be applied to create durable wear parts for processing equipment, including potential adaptations for severe abrasive conditions.

Frequently Asked Questions (FAQs)

Find answers to common technical questions about our Tungsten Carbide Crusher Blades and their applications in demanding plastic recycling.